Mold for blanking of instrument board middle transverse beam support

A technology for intermediate beams and instrument panels, which is applied in the field of molds for the blanking of instrument panel intermediate beam brackets, can solve the problems of high cost, complex mold structure, and unfavorable popularization and application, and achieve low cost, simple mold structure, and favorable promotion and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

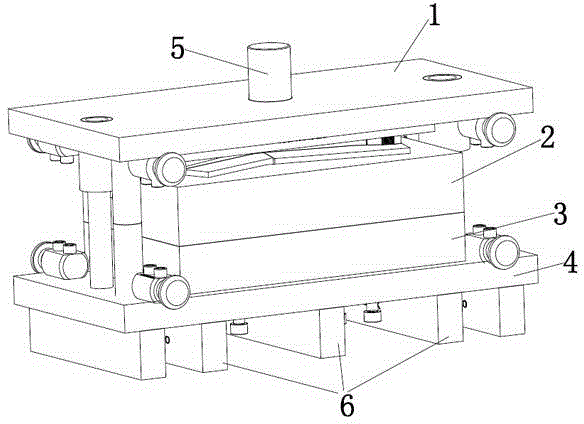

[0009] Such as figure 1 As shown, the present invention discloses a mold for forming the upper bracket of an instrument panel, which includes a front push plate 1, a front mold core 2, a rear mold core 3, and a rear push plate 4. The front mold core 2 and the front push plate 1 is connected, the rear mold core 3 is connected to the rear push plate 4, the front mold core 2 and the rear mold core 3 form a cavity, and the mold also includes a driving mechanism that drives the front push plate 1 to move , The rear mold core 3 is provided with a blanking hole.

[0010] The driving mechanism includes an air cylinder and a connecting rod 5 connected to the air cylinder, and the connecting rod 5 is connected to the front push plate 1.

[0011] The mold also includes a plurality of bases 6 installed at the bottom of the push plate 4. The bottom of the rear push plate 4 is also provided with screws, and the rear push plate 4 is fixed by the screws.

[0012] When in use, the driving mechanis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap