Aluminum alloy forging material for welded structural parts and manufacturing method thereof

A welding structure and manufacturing method technology, applied in the field of aluminum alloy forging materials and its manufacturing, can solve the problems of poor performance reproducibility of forging materials, prone to cracks, insufficient verification of the relationship between grain size and grain shape, etc. , to achieve the effect of excellent welding crack resistance and stress corrosion crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, embodiments of the aluminum alloy forged material for welded structural parts and its manufacturing method according to the present invention will be described in detail.

[0043] First, the forged material of the present invention will be described.

[0044] 〔Aluminum alloy forging material〕

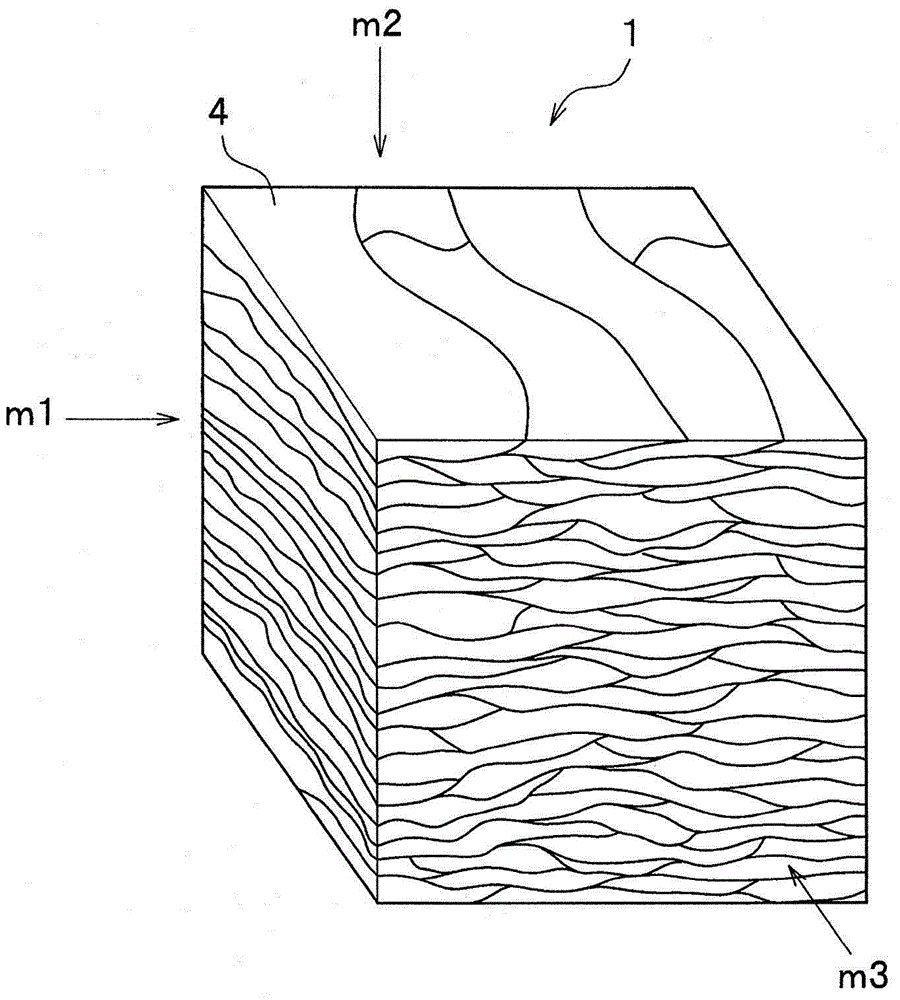

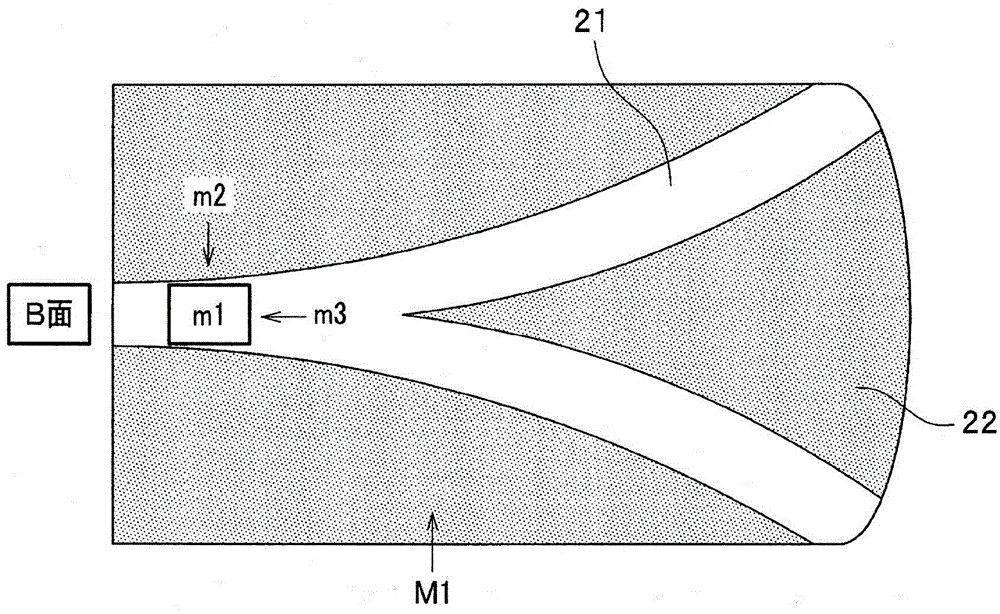

[0045] For an aluminum alloy forging material, in its structure, when the grain length of the long axis is GLμm, and the grain length of the short axis is GSμm, three directions perpendicular to each other observed at the part where the shear band is formed Among the faces, two faces are represented by the following formula, and the crystal grains of the remaining face are bent in the direction of the major axis.

[0046] 50≤GL≤500...(1)

[0047] 10≤GS≤180...(2)

[0048] GS≤GL...(3)

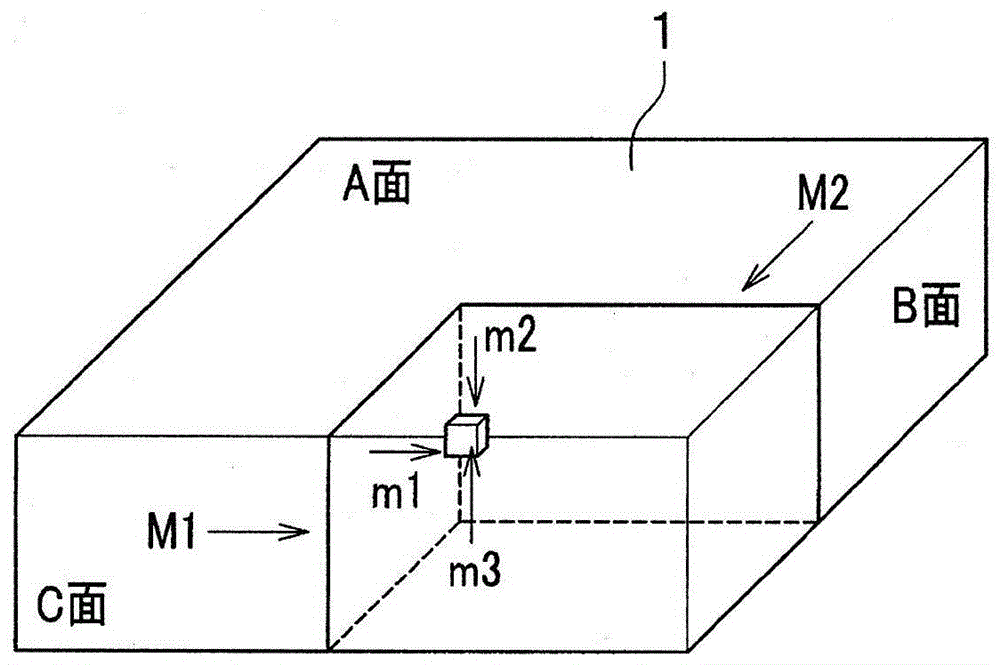

[0049] The configuration of the forged material of the present invention will be described. figure 1 It is a perspective view for explaining the structure observation position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com