Method and device for modifying organic sludge to prepare fuel oil

A technology for organic sludge and fuel oil, applied in sludge treatment, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of insufficient combustion of organic sludge, environmental pollution of organic sludge, etc., and achieve good flow flammability and flammability, and the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

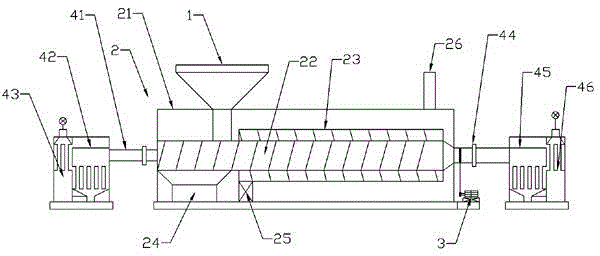

[0033] Example 1

[0034] The remaining sludge of the municipal sewage treatment plant is modified with a modifier. The modification temperature is controlled at 45°C to 60°C, and the modification time is controlled at 25 days. The modified residual sludge of the urban sewage treatment plant is transported to the feeding bin 2 through an external belt conveyor, and the residual sludge of the urban sewage treatment plant enters the positive thread in the reaction bin 2 after being measured. The delivery pipe 22. At this time, the furnace 24 uses gas or biomass fuel to heat the forward threaded conveying pipe 22, and the temperature is controlled at 330°C. At this time, the driving motor 3 drives the forward screw conveying pipe 22 to rotate forward and the reverse screw conveying pipe 23 to rotate in reverse. The remaining sludge of the urban sewage treatment plant is extracted inside the forward threaded conveying pipe 22, and the extracted oil and gas are respectively collecte...

Example Embodiment

[0036] Example 2

[0037] Add modifiers to the bottom mud of Heiwu River for modification. The modification temperature is controlled at 40℃ to 60℃, and the modification time is controlled at 30 days. The modified black and smelly river sludge is transported to the upper silo 1 via an external belt conveyor, and the black and smelly river sludge enters the forward thread entering the reaction chamber 2 after being metered. The delivery pipe 22. At this time, the furnace 24 uses gas or biomass fuel to heat the forward threaded conveying pipe 22, and the temperature is controlled at 400°C. At this time, the driving motor 3 drives the forward threaded conveying pipe 22 to rotate forward. And driving the reverse threaded conveying pipe 23 to reverse rotation. The bottom mud of the Heiwu River is extracted inside the forward threaded conveying pipe 2, and the extracted oil and gas are respectively collected through the first collection pipe 41 and the second collection pipe 44, and ...

Example Embodiment

[0039] Example 3

[0040] The filter mud produced by sugar refining is modified by adding a modifier. The modification temperature is controlled at 40°C to 60°C, and the modification time is controlled at 30 days. The modified filter mud is transported to the upper silo 1 through an external belt conveyor, and the filter mud enters the forward threaded conveying pipe 22 in the reaction chamber 2 after being metered. At this time, the furnace 24 uses gas or biomass fuel to heat the forward threaded conveying pipe 22, and the temperature is controlled at 350°C. At this time, the driving motor 3 drives the forward threaded conveying pipe 22 to rotate forward. And driving the reverse threaded conveying pipe 23 to reverse rotation. The filter mud is extracted inside the forward threaded conveying pipe 22, and the extracted oil and gas are respectively collected through the first collection pipe 41 and the second collection pipe 44, and the collected oil and gas pass through the first...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap