A method of dissolving max phase ceramic materials

A technology for ceramic materials and solutions, applied in the field of dissolving MAX phase ceramic materials, can solve the problems of difficult to achieve spent fuel reprocessing, difficult to dissolve cladding materials by chemical deshelling, and shell core separation, etc., to achieve good application prospects and reduce radioactivity. The generation of waste liquid and the effect of short dissolution cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

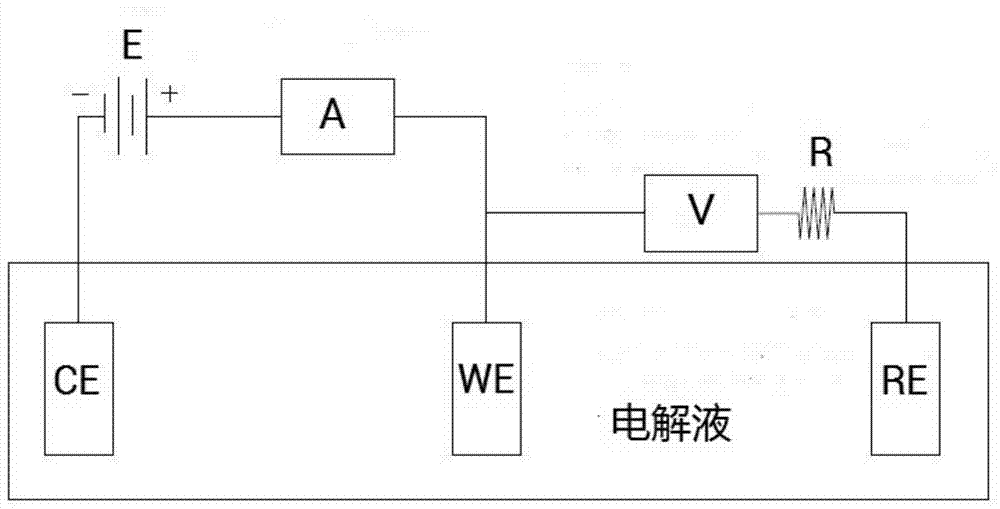

[0036] In this embodiment, the electrolytic technology is used to dissolve Ti 3 AlC 2 Bulk materials, specific electrolytic structures such as figure 1 shown. Among them, about 3mm thick Ti 3 AlC 2 The block is used as the working electrode (anode); the counter electrode (cathode) is a platinum sheet; the reference electrode is a saturated calomel electrode; the electrolyte is a mixed solution of HF and HCl, in which the mass of HF accounts for 1% and the mass of HCl accounts for 1%. The rest is water; the electrolysis temperature is room temperature.

[0037] The specific method is as follows:

[0038] (1) Prepare the required electrolyte;

[0039] (2) Measure about 80mL of electrolyte in a 100mL plastic beaker, and pass it through high-purity nitrogen for 15min to remove oxygen to form an electrolytic cell;

[0040] (3) Insert Ti on the electrolytic cell cover in turn 3 AlC 2 working electrode, platinum counter electrode and saturated calomel electrode, and the Ti ...

Embodiment 2

[0049] In this embodiment, the electrolytic technology is used to dissolve Ti 3 SiC 2 Bulk materials, specific electrolytic structures such as figure 1 shown. Among them, about 3mm thick Ti 3 SiC 2 The block is used as the working electrode (anode); the counter electrode (cathode) is a platinum sheet; the reference electrode is a saturated calomel electrode; the electrolyte is a mixed solution of HF and HCl, in which the mass of HF accounts for 1% and the mass of HCl accounts for 1%. The rest is water; the electrolysis temperature is room temperature.

[0050] The specific method is basically the same as the method in Example 1, the difference is that Ti is used 3 SiC 2 Bulk material replaces Ti 3 AlC 2 bulk material.

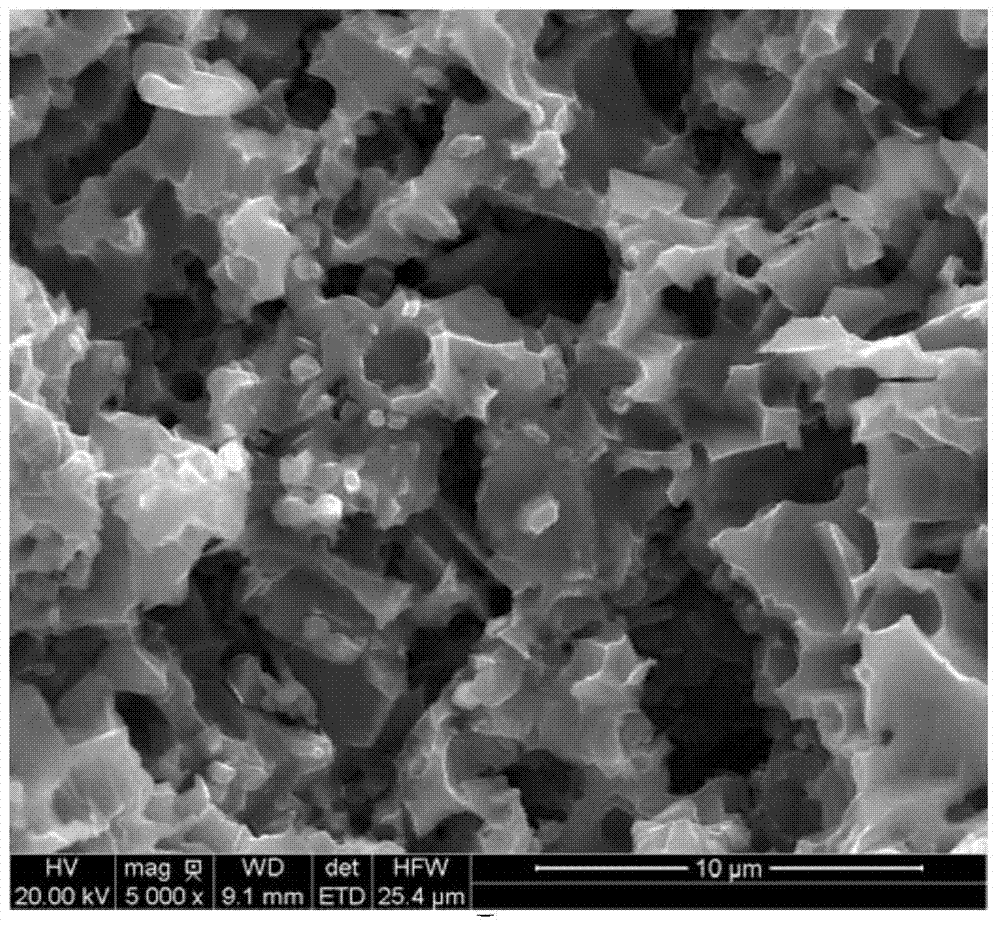

[0051] above Ti 3 SiC 2 The surface scanning electron microscope (SEM) photo of the material after 10 hours of constant voltage electrolysis is as follows image 3 shown. from image 3 It can be seen that Ti 3 SiC 2 Dissolution occurred on the s...

Embodiment 3

[0055] In this embodiment, the electrolytic technology is used to dissolve Ti 3 SiC 2 Bulk materials, specific electrolytic structures such as figure 1 shown. Among them, about 3mm thick Ti 3 SiC 2 The block is used as the working electrode (anode); the counter electrode (cathode) is a platinum sheet; the reference electrode is a saturated calomel electrode; the electrolyte is a mixed solution of HF and HCl, in which the mass of HF accounts for 1% and the mass of HCl accounts for 1%. The rest is water; the electrolysis temperature is room temperature.

[0056] The specific method is basically the same as that in Example 2, except that in step (4), the voltage applied by the electrochemical workstation is reduced from 0.8V (vs. SCE) to 0.6V (vs. SCE).

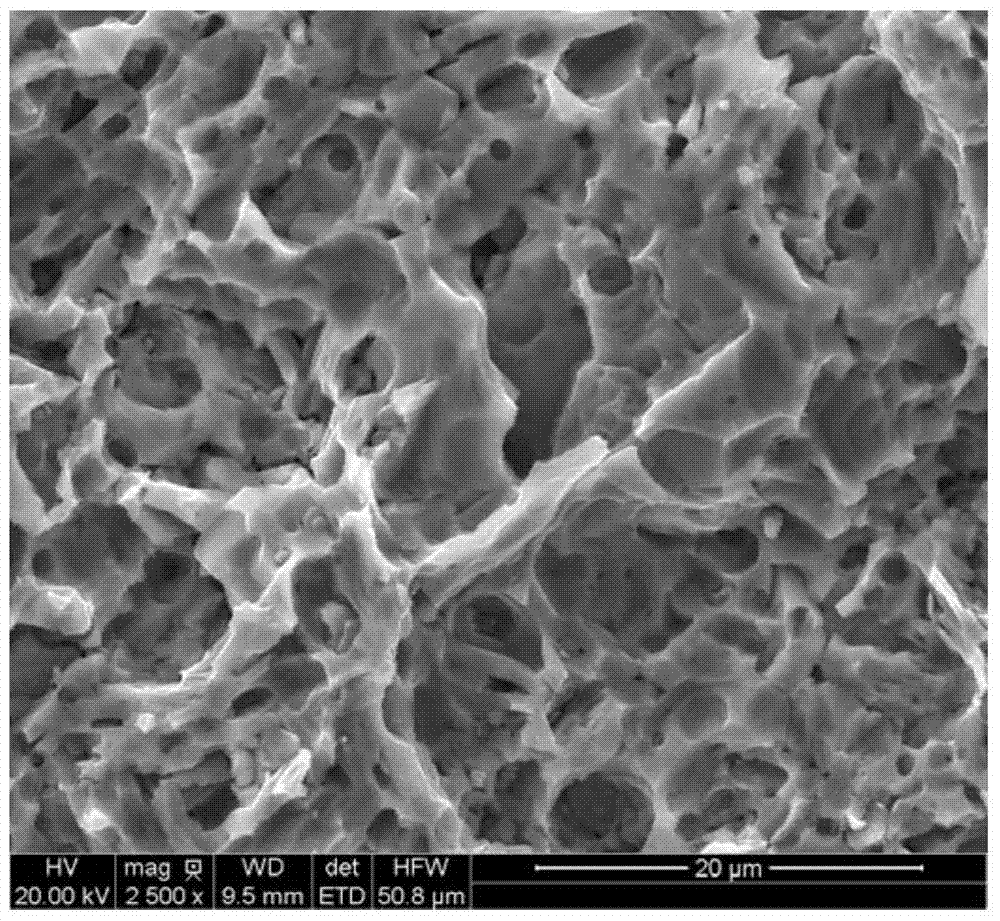

[0057] above Ti 3 SiC 2 The surface scanning electron microscope (SEM) photo of the material after 10 hours of constant voltage electrolysis is as follows Figure 4 shown. from Figure 4 It can be seen that Ti 3 SiC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com