Overload relief valve

A technology of unloading valve and valve body, applied in the field of hydraulic system, can solve the problems of large oil pressure difference, complicated connection and installation, complicated installation, etc., and achieve the effect of reducing cost, using less quantity, and simplifying the installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

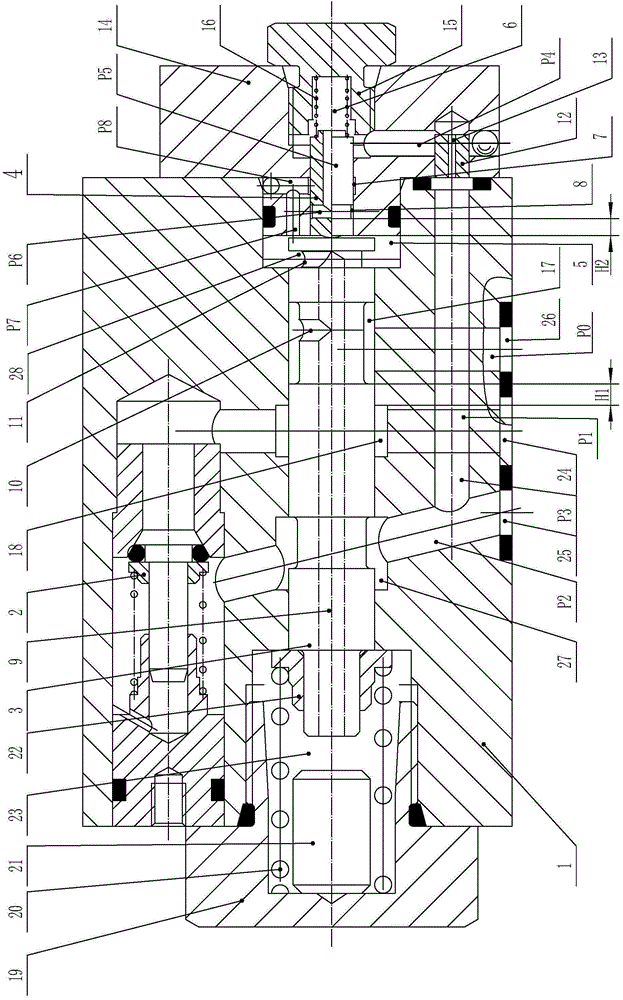

[0019] The overload relief valve of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0020] like figure 1 As shown, the overload relief valve of the present invention includes a valve body 1, a one-way valve 2, a main valve core 3, a control valve core 4, an oil inlet channel P1, an oil outlet channel P2, an oil return channel P0, a first spring adjustment A pressure mechanism, a second spring pressure regulating mechanism, a first oil passage mechanism, a second oil passage mechanism, a third oil passage mechanism, and a fourth oil passage mechanism. The check valve 2 is arranged on the upper part of the valve body 1, the oil inlet cavity of the check valve 2 is communicated with the oil inlet passage P1, and the oil outlet chamber of the check valve 2 is communicated with the oil outlet passage P2. The main valve core 3 can slide left and right in the valve body 1 , and a first sealing oil cavity...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap