Treatment method for oil product refining waste alkaline solution

A treatment method and technology of waste lye, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems that are not used as inspection indicators, and achieve reduction of reagent usage, Achieve zero discharge, reduce phenol concentration and COD effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

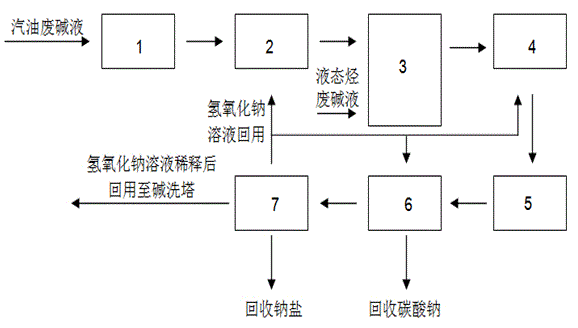

Image

Examples

Embodiment 1

[0034] A stock of gasoline waste lye, its COD is 536000mg / L, S 2- The concentration is 12700mg / L, the phenol concentration is 196000mg / L, the sodium carbonate concentration is 23760mg / L, the sodium hydroxide concentration is 2.6wt%, and the oil is 190mgL. A waste lye containing organic nitrogen liquid hydrocarbon, its COD is 179000mg / L, the organic nitrogen concentration is 8730mg / L, S 2- The concentration is 35800mg / l, the phenol concentration is 32300mg / L, the sodium carbonate concentration is 10800mg / L, the sodium hydroxide concentration is 3.5wt%, and the oil is 150mg / L. The method of the present invention is used for treatment under the following conditions:

[0035] (1) Acidification and neutralization: Add concentrated sulfuric acid to the spent lye of gasoline. When the pH value of the spent lye is 3-4, stop adding acid, stir for 30 minutes, and stand still for 24 hours. After acidification, the waste lye is divided into upper and lower layers. The upper layer is organic ...

Embodiment 2

[0043] A stock of gasoline waste lye, its COD is 396800mg / L, S 2- The concentration is 9360mg / l, the phenol concentration is 147000mg / L, the sodium carbonate concentration is 18390mg / L, the sodium hydroxide concentration is 2.9wt%, and the oil is 173mgL. A waste lye containing organic nitrogen liquid hydrocarbon, its COD is 158200mg / L, the organic nitrogen concentration is 7240mg / L, S 2- The concentration is 29320mg / l, the phenol concentration is 28240mg / L, the sodium carbonate concentration is 9920mg / L, the sodium hydroxide concentration is 3.8wt%, and the oil concentration is 135mg / L. The method of the present invention is used for treatment under the following conditions:

[0044] (1) Acidification and neutralization: Add concentrated sulfuric acid to the waste lye of gasoline. When the pH value of the waste lye is 5-6, stop adding acid, stir for 30 minutes, and stand still for 24 hours. After acidification, the waste lye is divided into upper and lower layers. The upper l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com