Ultraviolet curing device

A curing device and ultraviolet technology, which are applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of high production cost, complex and rigid structure, unfavorable promotion and use, etc., to improve the curing efficiency and structure. Simple and flexible, widely used value and the effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

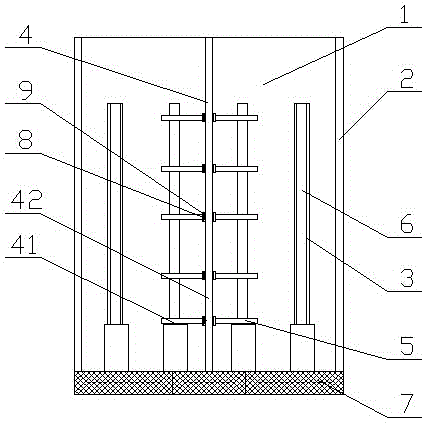

[0017] like figure 1 As shown, an ultraviolet curing device includes a curing chamber 1;

[0018] Wherein, described solidification cavity 1 is provided with the baffle plate 2 that inner liner is mirror surface stainless steel, and described solidification cavity 1 bottom and top surface layer are all mirror surface stainless steel materials; The bottom of described solidification cavity 1 is equipped with motor 7;

[0019] In the baffle plate 2, ultraviolet lamps 6 and placement racks 4 are sequentially arranged, and the ultraviolet lamps 6 are multiple, corresponding to the number of placement racks 4, and arranged vertically, evenly surrounding the placement racks 4; Frame 4 is provided with a plurality of placement discs 5 from top to bottom, and each placement disc 5 is provided with a slide shaft 8 on the contact surface with the placement rack 4, and is instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap