Special tubular screw conveyor casing for bottle flakes

A screw conveyor and tube-type technology, which is applied in the casing of the tube-type screw conveyor for bottle flakes, can solve the problems of small contact area between the material and the casing, the efficiency of blocking and winding conveying, and small friction, so as to reduce the equipment The effect of repair and maintenance cost, improvement of practical performance, and increase of friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

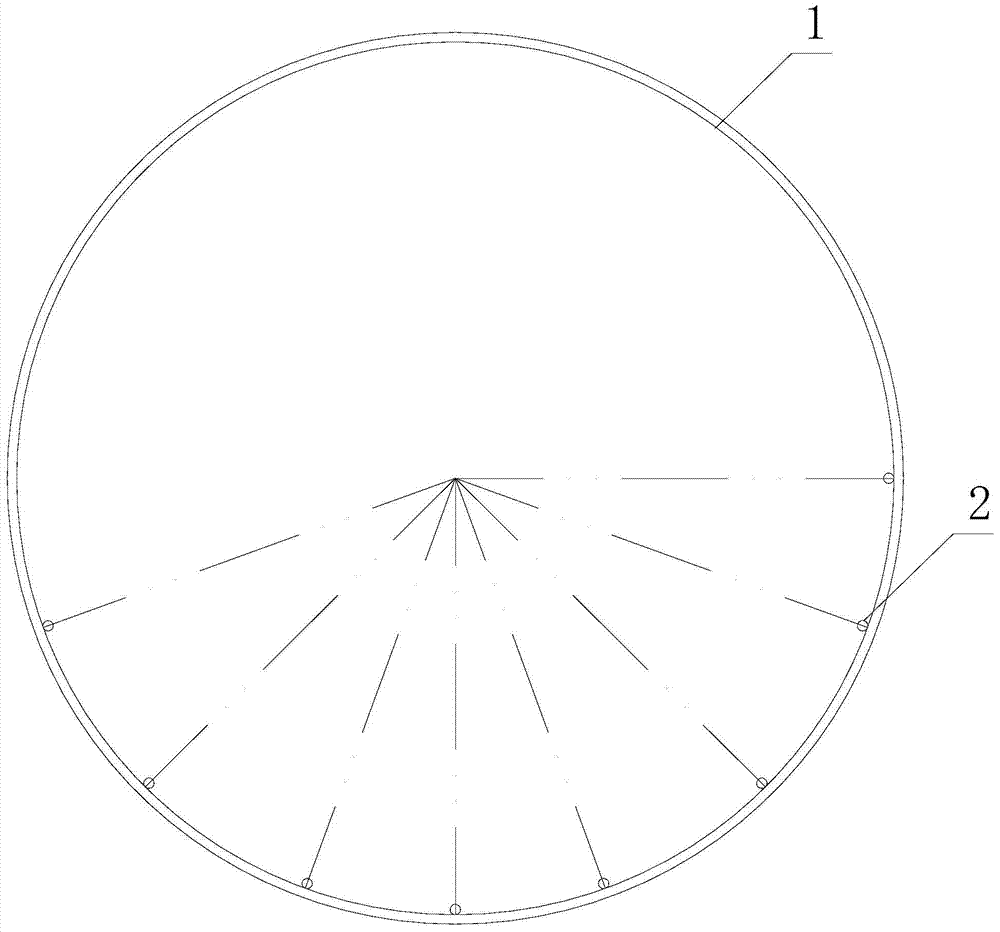

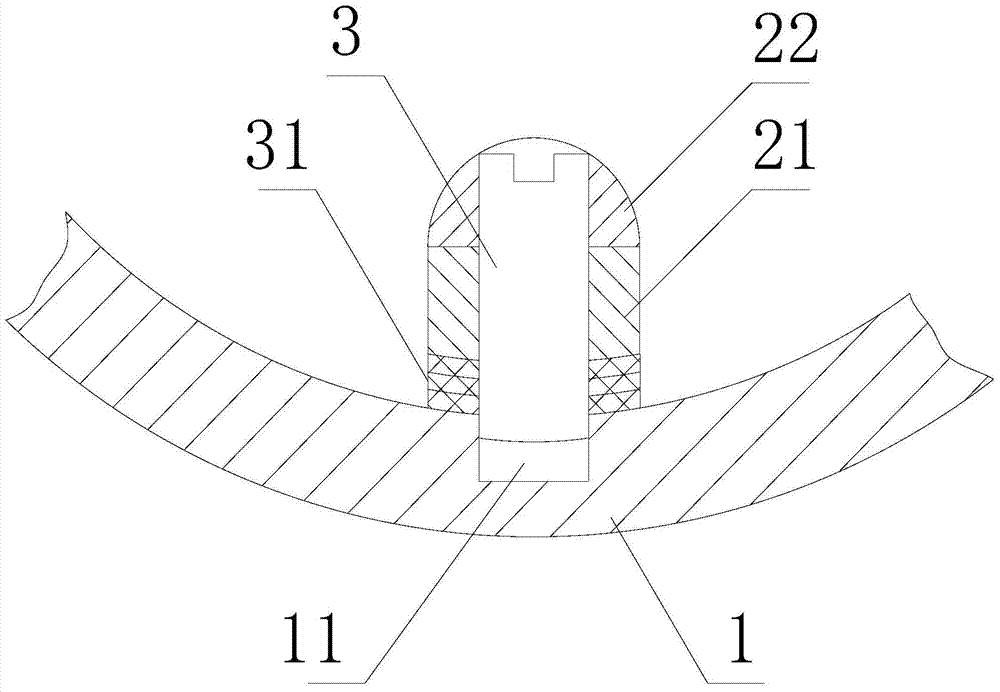

[0016] like figure 1 , figure 2 As shown, the shell of the special tubular screw conveyor for bottle flakes includes a shell 1, and the inner wall of the shell 1 is provided with a rib 2 that increases the friction of the shell 1, and the rib 2 is inside the shell 1. Distributed in a fan shape, the height of the rib 2 in the housing 1 is adjustable, the longitudinal section of the top of the rib 2 is arc-shaped, the rib 2 is fixedly connected to the housing 1 through the fastening screw 3, and the housing 1 is provided with The threaded hole 11 for fixing the fastening screw 3, the fastening screw 3 is provided with a gasket 31 for adjusting the height of the convex rib 2, the gasket 31 is arranged between the shell 1 and the convex rib 2, the fastening screw is connected reliably, and the use The effect is good, and the height of the convex rib in the housing is adjusted through the gasket, which can be adjusted according to different types of materials, and the practical p...

Embodiment 2

[0020] As for the casing of the special tubular screw conveyor for bottle flakes described in Embodiment 1, this embodiment has the following difference: the included angles formed between two adjacent ribs 2 are all equal, which can make the inner wall of the casing equal The friction force, the material conveying effect is good.

Embodiment 3

[0022] As for the casing of the special tubular screw conveyor for bottle flakes described in Embodiments 1 and 2, this embodiment has the following differences: an adjustable angle is formed between two adjacent convex ribs 2, and the base 21 It is movably connected on the inner side wall of the housing 1, and the housing 1 is provided with strip-shaped holes for fastening screws to be installed.

[0023] When in use, the height of the rib 2 in the housing 1 is adjusted according to the size of the material, and the height of the rib 2 can be adjusted only by adjusting the gasket or nut on the fastening screw 3. The shell 1 produces a height difference, which increases the friction of the shell 1, and the material can no longer be blocked and entangled in the shell 1, so that the material can be transported quickly and safely.

[0024] The friction force of the shell is effectively increased by the ribs provided in the shell, so that there will be no material clogging and win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com