A kind of liquid phase solvent and its application of acetylene hydrogenation preparation ethylene slurry state bed

A liquid-phase solvent and acetylene hydrogenation technology, applied in the field of industrial production of ethylene, can solve the problems of few explorations and unreported large-scale industrial application, so as to improve selectivity, prolong life and device start-up time, and avoid acetylene aggregated effect

Active Publication Date: 2016-11-23

北京锦泰诚瑞科技发展有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Although the selective hydrogenation of acetylene is a current focus of attention, its research content is mainly applied to the removal of trace amounts of acetylene (0.01-5% by volume) in the process of producing ethylene from petroleum hydrocarbon cracking, and for the catalytic selective hydrogenation that uses high-concentration acetylene as raw material. Hydrogenation ethylene process and catalysts are rarely explored, and the corresponding large-scale industrial application has not been reported.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

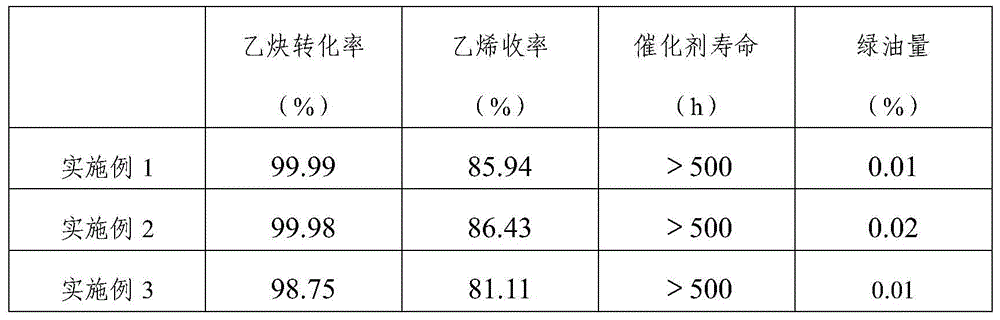

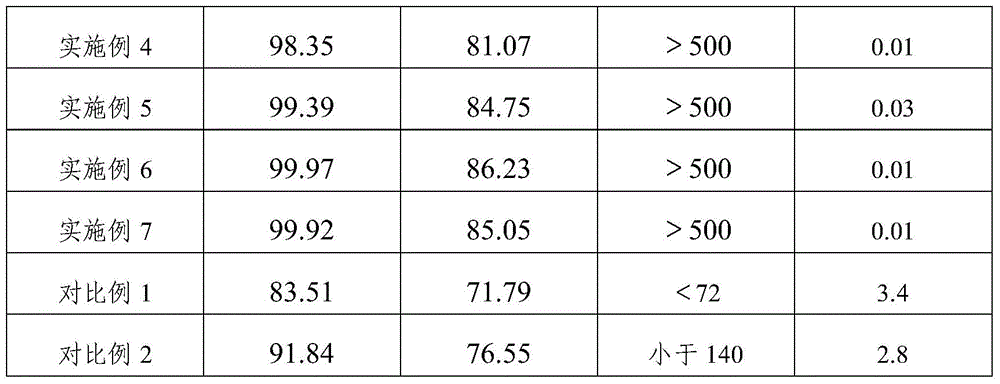

Effect test

Embodiment 1

[0018] The composition of the liquid phase solvent: [BMIM][BF 4 ] 15g, tetralin 10g, N-methyl-2-pyrrolidone 75g.

Embodiment 2

[0020] The composition of the liquid phase solvent: [BMIM][BF 4 ] 10g, tetralin 8g, N-methyl-2-pyrrolidone 82g.

Embodiment 3

[0022] The composition of the liquid phase solvent: [BMIM][BF 4 ]3g, [BMPyrr][EtHPO 3 ]3g, dihydroanthracene 5g, N-methyl-2-pyrrolidone 60g, ethylenediamine 29g.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a liquid-phase solvent for preparing an ethylene slurry bed through acetylene hydrogenation. The liquid solvent comprises the following components in parts by weight: 0.5 to 15 parts of ionic liquid, 0.5 to 10 parts of hydrogen donor and 75 to 105 parts of electron donor solvent. The liquid-phase solvent provided by the invention has good hydrogen donating capacity, hydrogen free radical transfer capacity and green oil dissolving capacity, the green oil coverage amount is greatly reduced and the service life of a catalyst is prolonged. The invention further protects application of the liquid solvent to the process for preparing the ethylene slurry bed through acetylene hydrogenation.

Description

technical field [0001] The invention relates to the field of industrial production of ethylene, in particular to a liquid phase solvent for preparing ethylene slurry bed by hydrogenation of acetylene. Background technique [0002] With the depletion of petroleum resources, the development of coal chemical industry as a raw material chemical process has become an important process to replace the petrochemical route, which has attracted widespread attention and achieved rapid development. [0003] Ethylene is the most important basic raw material in petrochemical industry, known as "the mother of petrochemical industry". Widely used in plastics, lubricating oils, polymers and some intermediates, currently mainly produced from petroleum or low-carbon alkanes through cracking. In coal chemical technology, the production of acetylene by using coal as raw material through calcium carbide process has been widely used. Using acetylene as raw material under the action of selective h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07C5/09C07C11/04

CPCY02P20/54

Inventor 余海鹏史雪君车中山吴道洪

Owner 北京锦泰诚瑞科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com