Oval building prefabricated column

An elliptical, prefabricated column technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of high brittleness of the pile body, low ductility of the pile body, and large steel consumption, so as to improve the seismic strength and save steel , to avoid the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The detailed structure of the present invention will be further described below in conjunction with the drawings and specific embodiments.

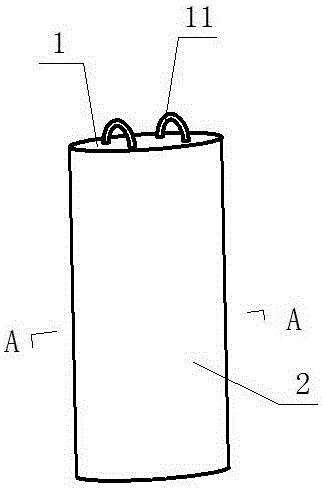

[0012] Such as figure 1 , figure 2 As shown, an elliptical prefabricated column includes a column body 2 and a lifting plate 1 fixed on the upper end of the column body 2. The upper end of the lifting plate 1 is provided with a lifting ring 11, and the lifting plate 1 and a steel frame provided inside the column 2 Connected, the cross section of the cylinder 2 is elliptical.

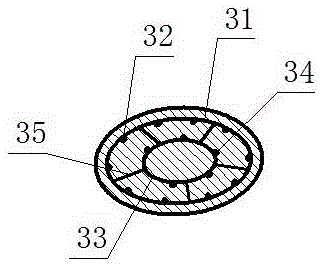

[0013] The steel frame includes pre-stressed steel bars 32 and non-pre-stressed steel bars 34. The pre-stressed steel bars 32 are connected into one body through an outer steel frame cage 31, and the non-prestressed steel bars 34 are connected into one body through an inner steel frame cage 33. The pre-stressed steel bars 32 The upper end of the is connected with the lifting plate 1.

[0014] The outer steel frame cage 31 and the inner steel frame cage 33 are con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap