A billet temperature modeling and online correction method for a walking heating furnace

A technology of a walking heating furnace and a calibration method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as poor practical application effects, low prediction accuracy, and numerous parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

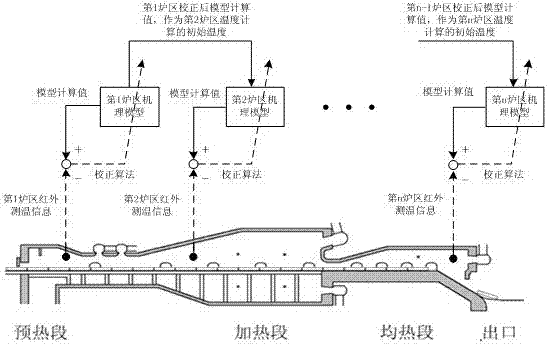

[0083] The establishment and correction process of the billet temperature model of the walking heating furnace in the present embodiment are as follows:

[0084] Step S1: For each furnace zone of the walking heating furnace, the heat exchange principle is used to establish the temperature mechanism model of the billet in each furnace zone offline.

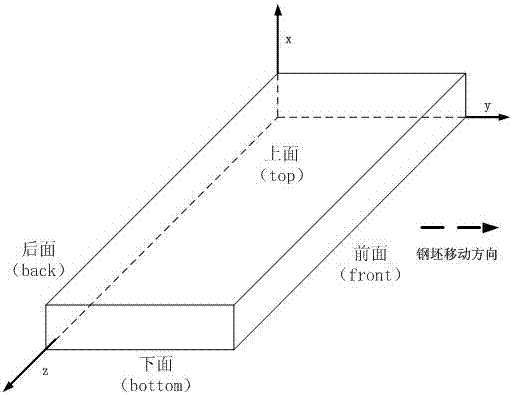

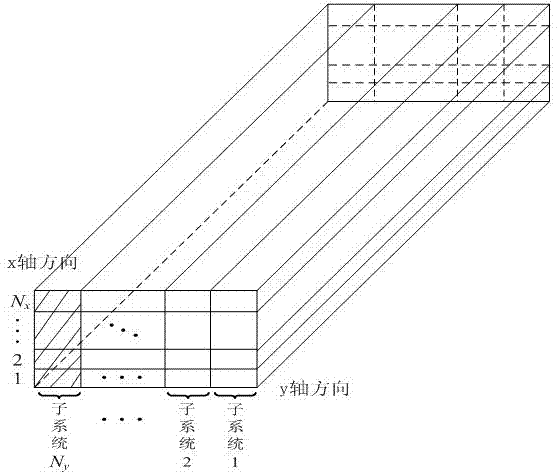

[0085] In this embodiment, the two-dimensional temperature model of a steel billet is taken as an example to describe the establishment process of the steel billet temperature mechanism model. In this embodiment, in order to establish a billet tracking model based on spatial coordinates, press figure 1 Create a space coordinate system as shown.

[0086] The billet two-dimensional temperature model ignores the distribution of billet temperature in the heating furnace along the billet width direction (that is, the z-axis direction), that is, the billet temperature in this direction is considered to be the same everywhere, that is, the...

Embodiment 2

[0167] In this embodiment, except that the optimization algorithm used is different from that in Embodiment 1, the rest of the content and steps are the same as in Embodiment 1.

[0168] In this embodiment, the grid calculation method is used to optimize the equivalent heat transfer coefficient, wherein the specific implementation of the grid calculation method is as follows:

[0169] Step 1: Determine the equivalent comprehensive heat transfer coefficient K according to production experience and model mechanism eq The optimization space of K eq ∈[K min ,K max ];

[0170] Step 2: given the optimal space division, assuming the number of searches N s , then the search step size is

[0171] L s =(K max -K min ) / N s

[0172] Step 3: Let K eq =K min ;

[0173] Step 4: Use the current equivalent heat transfer coefficient K eq , initial billet temperature temperature cloth X 0,all And formulas (8), (9), (10), calculate the average predicted temperature difference calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com