A production system and preparation method of a catalyst for the selective hydrogenation of benzene to cyclohexene

A technology for selective hydrogenation and production systems, applied in the production of bulk chemicals, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

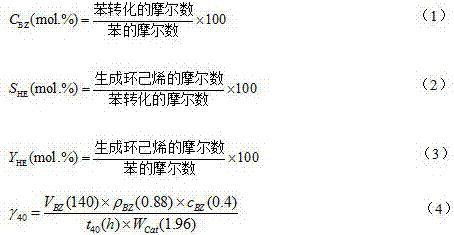

Examples

Embodiment 1

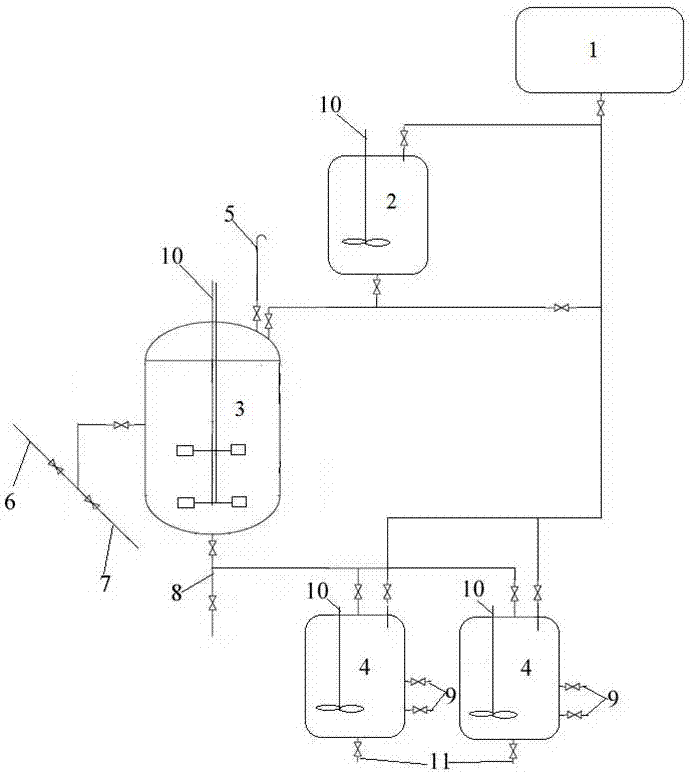

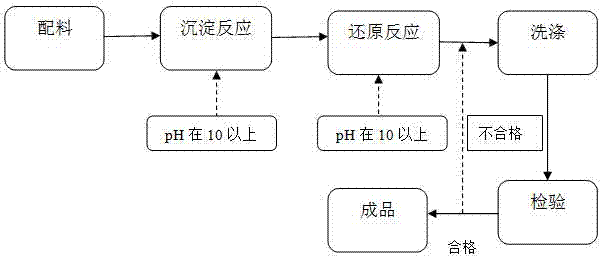

[0027] like figure 1 As shown, a production system for catalysts for the selective hydrogenation of benzene to cyclohexene: the production system includes a head tank 1, a batching tank 2, an autoclave 3, and a washing tank group arranged at intervals from top to bottom. The tank group includes two washing tanks 4, the batching tank 2 is located at the left obliquely below the high level tank 1, the autoclave 3 is located at the left obliquely below the batching tank 2, the washing tank 4 is located at the right obliquely below the autoclave 3, the bottom of the high level tank 1 is respectively connected to the batching The tops of tank 2, autoclave 3, and washing tank 4 are connected (the tops of batching tank 2, autoclave 3, and washing tank 4 are also connected to the bottom of elevated tank 1), and the top of autoclave 3 is provided with exhaust pipe 5, and The top of the autoclave 3 is connected to the bottom of the head tank 1 and also connected to the bottom of the bat...

Embodiment 2

[0045] A production system of a catalyst for the selective hydrogenation of benzene to cyclohexene is the same as in Example 1.

[0046] Utilize above-mentioned production system to prepare the method for benzene selective hydrogenation to prepare cyclohexene catalyst, operation steps are as follows:

[0047] (1) Ingredients: First add water to the batching tank 2 through the head tank 1, then add sodium hydroxide under stirring to prepare lye, the mass ratio of sodium hydroxide to water is 1:5, and then add the alkali The liquid is imported into the autoclave 3 from the batching tank 2, and the agitator 10 of the autoclave 3 is opened at the same time, and the rotating speed is 120 r / min; Add water, stir and dissolve, and prepare salt solution, the mass ratio of ruthenium trichloride hydrate and water is 1:10; then import the salt solution into autoclave 3, the mixing ratio of salt solution and lye Guarantee ruthenium trichloride hydrate: the mol ratio of sodium hydroxide is...

Embodiment 3

[0059] A production system of a catalyst for the selective hydrogenation of benzene to cyclohexene is the same as in Example 1.

[0060] Utilize above-mentioned production system to prepare the method for benzene selective hydrogenation to prepare cyclohexene catalyst, operation steps are as follows:

[0061] (1) Ingredients: first add water to the batching tank 2 through the head tank 1, then add sodium hydroxide under stirring to prepare lye, the mass ratio of sodium hydroxide to water is 1:7, and then add the alkali The liquid is imported into the autoclave 3 from the batching tank 2, and the agitator 10 of the autoclave 3 is opened at the same time, and the rotating speed is 135 r / min; Add water, stir and dissolve, and prepare salt solution, the mass ratio of ruthenium trichloride hydrate and water is 1:12; then import the salt solution into autoclave 3, the mixing ratio of salt solution and lye Guarantee ruthenium trichloride hydrate: the mol ratio of sodium hydroxide is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com