Preparation of epoxy resin adhesive and application of epoxy resin adhesive in friction matching pair molding process

A technology of epoxy resin and molding process, applied in the direction of modified epoxy resin adhesive, adhesive type, adhesive heating bonding method, etc. Improve transportation experimental conditions and other issues to achieve the effect of enhanced wear resistance, reduced friction coefficient, and reduced gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

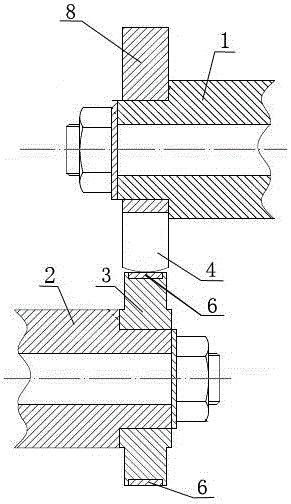

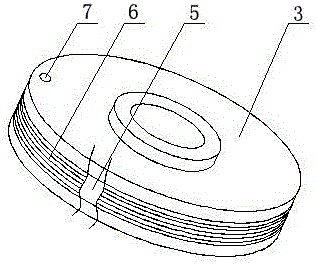

Image

Examples

Embodiment 1

[0023] The preparation method of epoxy resin adhesive comprises the following steps: Step 1. According to the molar ratio of 1:2, take epoxy resin and p-hydroxyanisole in a flask and heat it to 90°C in an oil bath, and then dropwise add acrylic acid and Prepare a mixed solution with p-dimethylbenzylamine, continue to heat up to 110°C, take 0.3g of the mixed solution as a sample, and titrate the acid value of the sample with a standard solution of potassium hydroxide ethanol with a concentration of 0.1mol / L. When the value is less than 3mgKOH / g, stop heating to prepare epoxy acrylate monoester for later use;

[0024] Step 2. According to the weight ratio of 3:2.25:0.24:0.24:10, weigh the polyurethane prepolymer, reactive diluent, photoinitiator, curing agent and the epoxy acrylate monoester prepared in step 2 and mix them to obtain Colloidal mixture, spare:

[0025] Step 3. According to the weight ratio of 1:3:3, weigh the microcapsule powder, white carbon black and absolute e...

Embodiment 2

[0028] The preparation method of epoxy resin adhesive comprises the following steps: Step 1. According to the molar ratio of 1:2, take epoxy resin and p-hydroxyanisole in a flask and heat it to 90°C in an oil bath, and then dropwise add acrylic acid and Prepare a mixed solution with p-dimethylbenzylamine, continue to heat up to 110°C, take 0.5g of the mixed solution as a sample, and titrate the acid value of the sample with a standard solution of potassium hydroxide ethanol with a concentration of 0.1mol / L. When the value is less than 3mgKOH / g, stop heating to prepare epoxy acrylate monoester for later use;

[0029] Step 2. According to the weight ratio of 3:2.25:0.24:0.24:10, weigh the polyurethane prepolymer, reactive diluent, photoinitiator, curing agent and the epoxy acrylate monoester prepared in step 2 and mix them to obtain Colloidal mixture, spare:

[0030] Step 3. According to the weight ratio of 1:3:3, weigh the microcapsule powder, white carbon black and absolute e...

Embodiment 3

[0033] The preparation method of epoxy resin adhesive comprises the following steps: Step 1. According to the molar ratio of 1:2, take epoxy resin and p-hydroxyanisole in a flask and heat it to 90°C in an oil bath, and then dropwise add acrylic acid and Prepare a mixed solution with p-dimethylbenzylamine, continue to heat up to 110°C, take 0.45g of the mixed solution as a sample, and titrate the acid value of the sample with a standard solution of potassium hydroxide ethanol with a concentration of 0.1mol / L. When the value is less than 3mgKOH / g, stop heating to prepare epoxy acrylate monoester for later use;

[0034] Step 2. According to the weight ratio of 3:2.25:0.24:0.24:10, weigh the polyurethane prepolymer, reactive diluent, photoinitiator, curing agent and the epoxy acrylate monoester prepared in step 2 and mix them to obtain Colloidal mixture, spare:

[0035] Step 3. According to the weight ratio of 1:3:3, weigh the microcapsule powder, white carbon black and absolute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com