A laser three-dimensional measuring system and its measuring method

A laser three-dimensional measurement system technology, applied in the field of laser measurement, can solve the problems of low inspection efficiency of inspectors, large manpower and time occupation, loss of company money and reputation, etc., to achieve the effect of improving detection efficiency and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention discloses a real-time contour tracking laser three-dimensional measurement system and measurement method, figure 1 It is a stereogram for three-dimensional measurement of an object of any shape, which is the object to be measured 100 of the present invention.

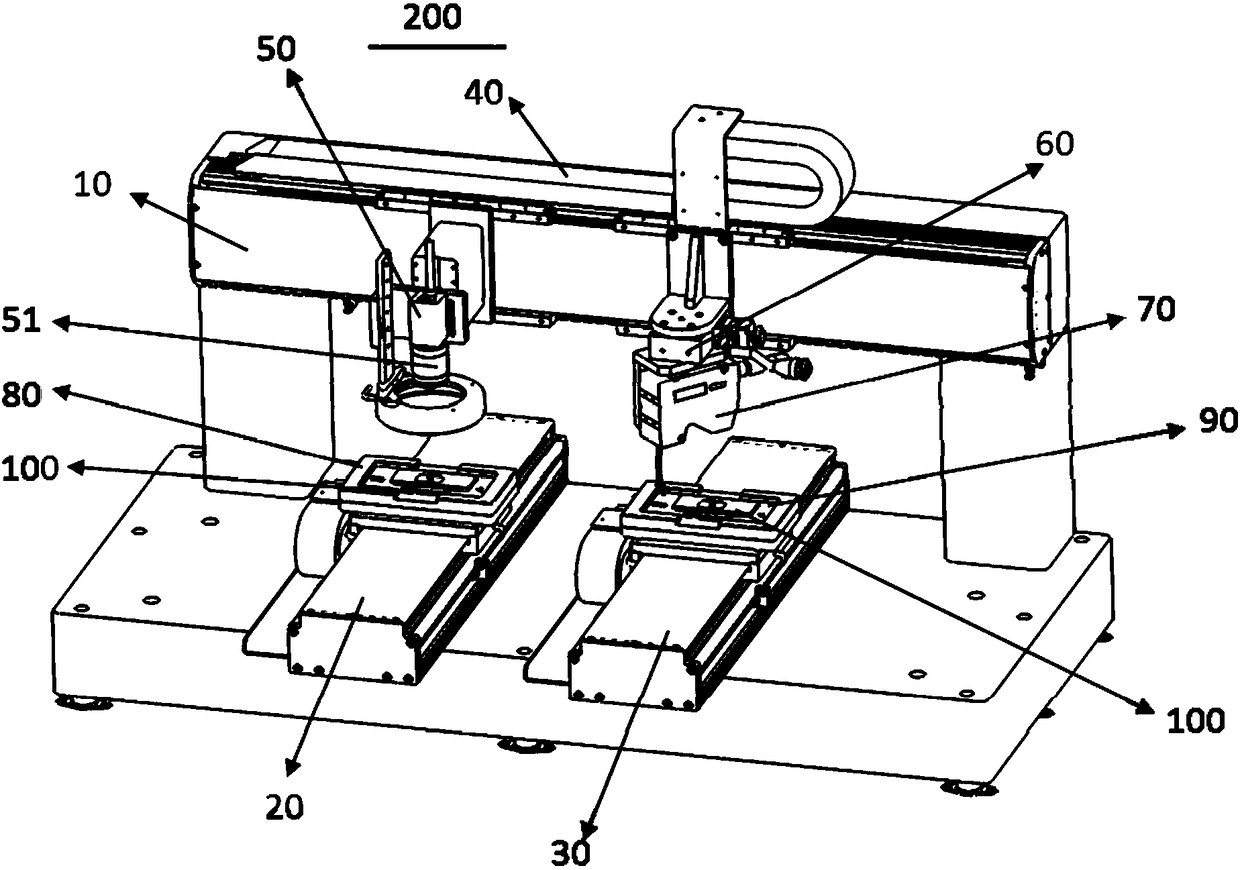

[0042] figure 2 It is a structural schematic diagram of an embodiment of the laser three-dimensional measurement system of the present invention. The laser three-dimensional measurement system 200 includes: an X motion axis 10; a plurality of Y motion axes perpendicular to the X motion axis, including two Y motion axes in this embodiment: A Y motion axis 20, a second Y motion axis 30 parallel to the first Y motion axis 20; a motion control system 40 fixed on the X motion axis 10, a CCD area array image acquisition device 50 fixed on the X motion axis 10 And the automatic rotary motion slide table 60, the laser three-dimensional measuring device 70 fixed on the automatic rotary motion slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com