Composite circuit protection structure resistant to high temperature and high overload

A composite circuit and protective structure technology, applied in the testing of machines/structural components, electrical components, electrical equipment enclosures/cabinets/drawers, etc., can solve problems such as non-removable, non-reusable, and impact-resistant without impact resistance , to achieve the effect of prolonging service life, good protection effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

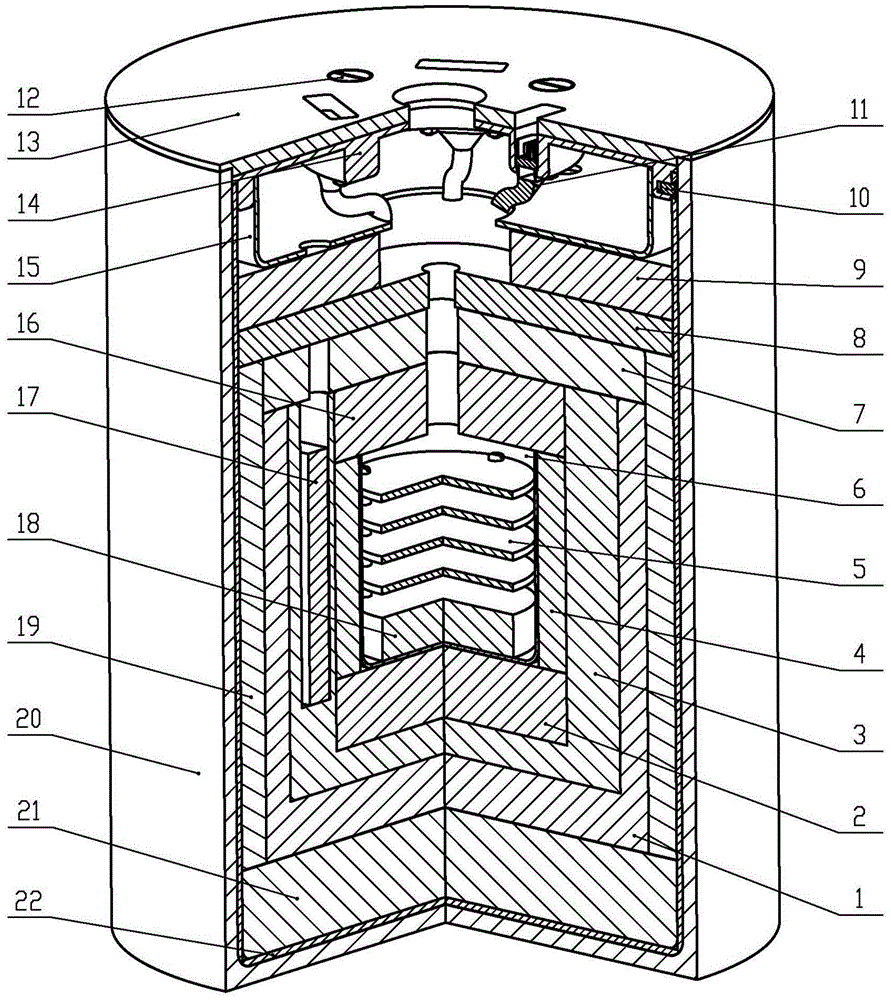

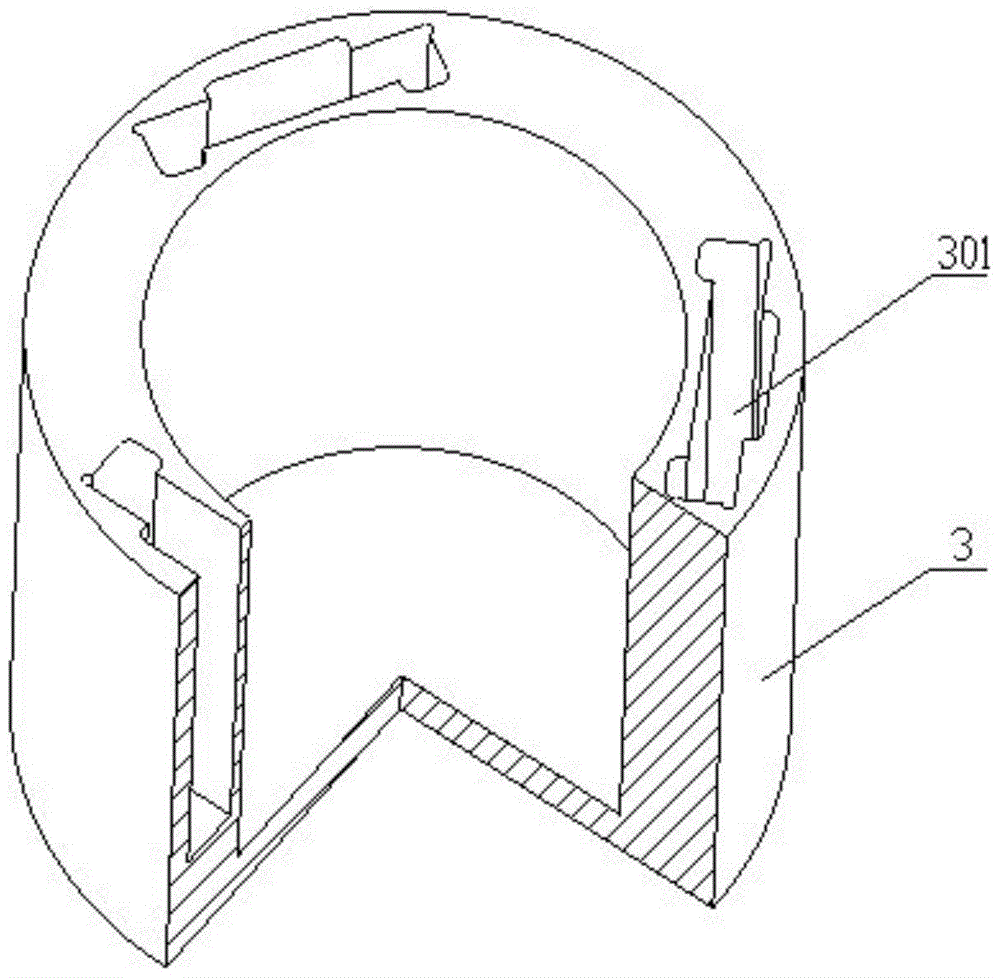

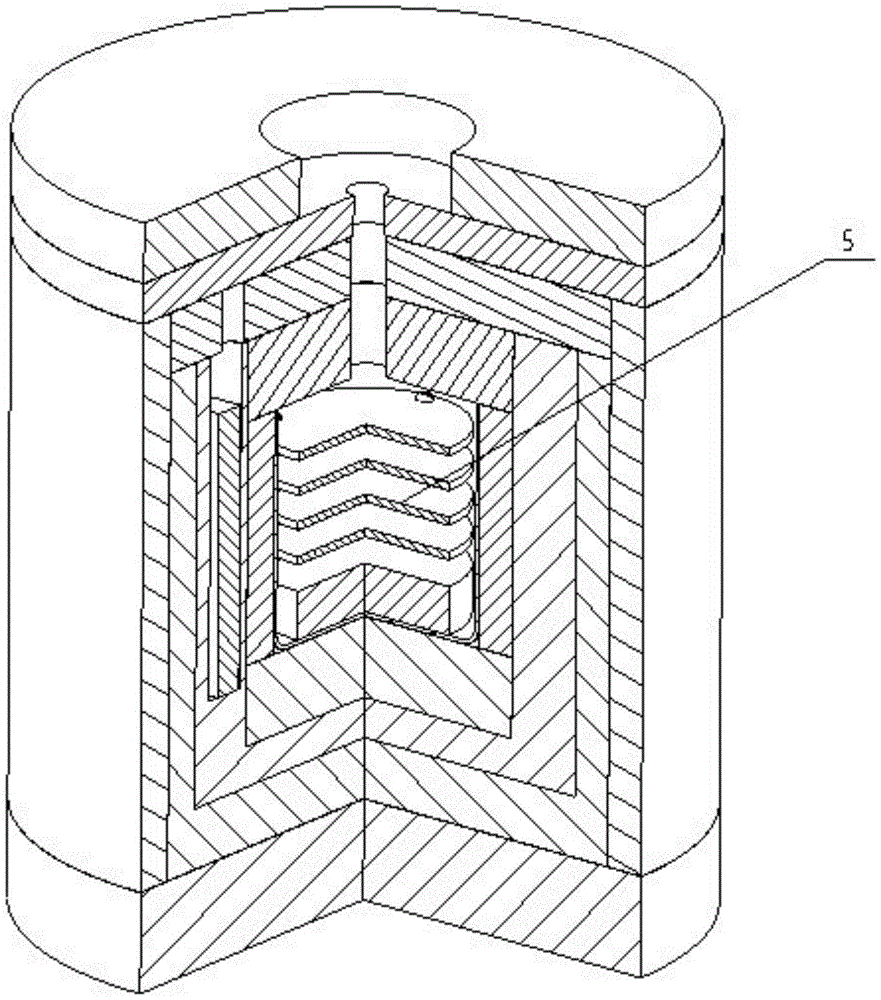

[0026] The present invention will be further explained below in conjunction with the drawings:

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention includes an outer shell. The outer shell includes a cylindrical PTFE shell 20 and a titanium alloy shell 22. The titanium alloy shell 22 is placed in the PTFE shell 20. The titanium alloy shell 22 is provided with polytetrafluoroethylene. The tetrafluoroethylene battery rack 3 and the multi-level buffer module. The multi-level buffer module includes four-level buffer layers. The four-level buffer layers are arranged from the inside to the outside and are the potting reinforcement layer of the circuit module, the internal glass wool buffer insulation layer, and the middle part. The rubber buffer layer and the outer glass wool buffer and heat insulation layer. The PTFE battery rack 3 is located between the inner glass wool buffer and heat insulation layer and the middle rubber buffe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap