A combined process of ngl (liquefied natural gas recovery) and lng (liquefied natural gas)

A technology for liquefied natural gas, liquid state, used in the field of LNG and LNG recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

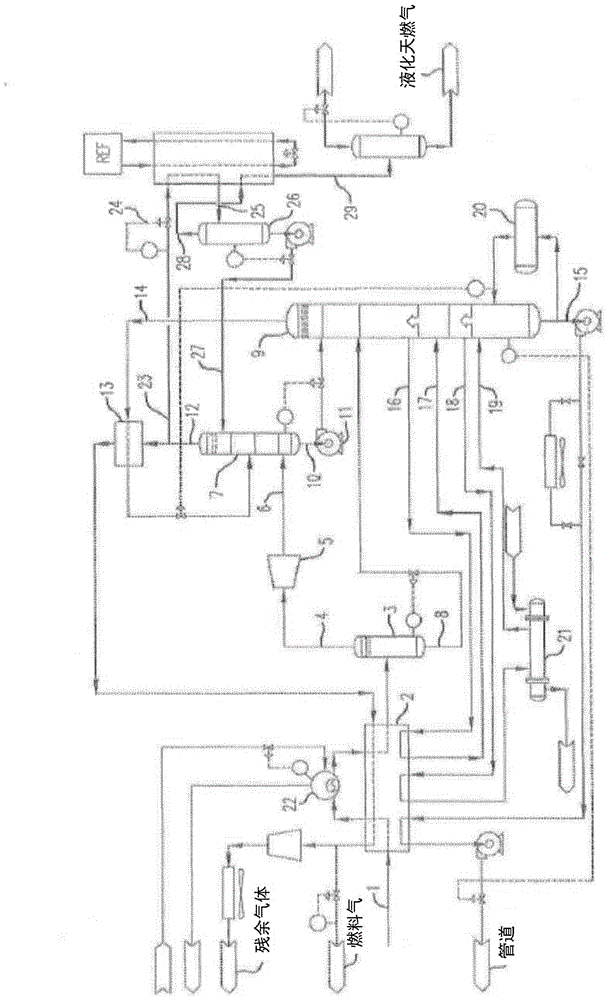

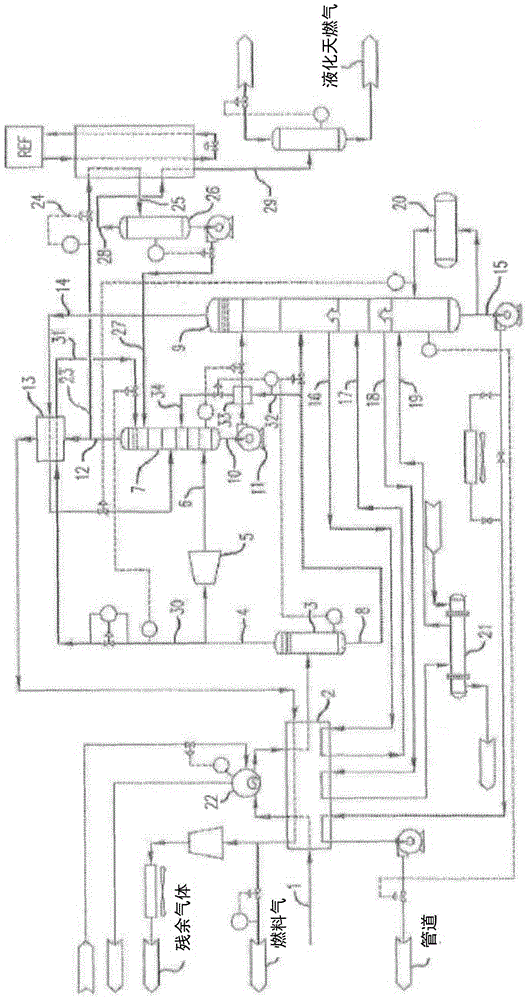

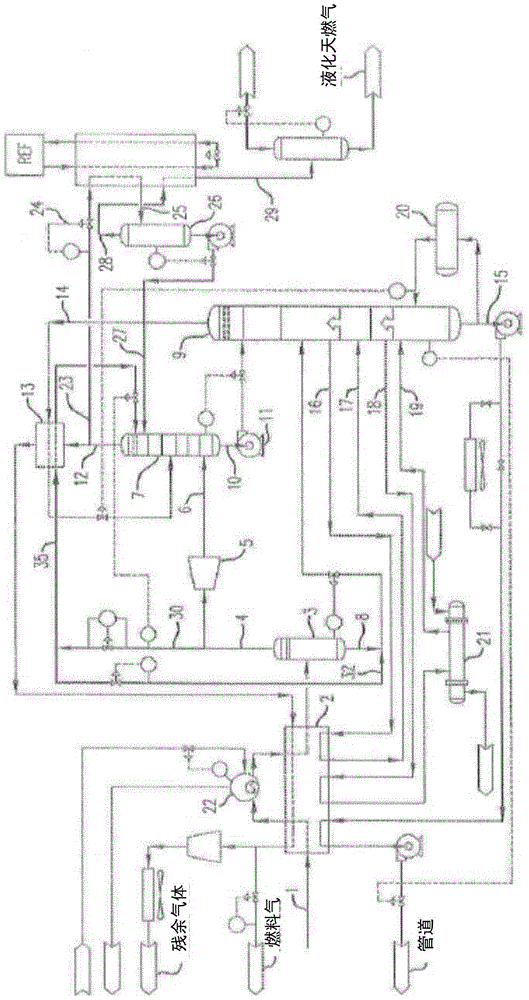

[0246] figure 1 In, the gas feed stream (1) (for example, a natural gas feed stream) comprising such as helium, nitrogen, methane, ethane, ethylene and hydrocarbons with a carbon number of 3 or more (for example, a natural gas feed stream) at a temperature of for example 10-50° C. , eg 250-1400 psig pressure is introduced into the system. The gaseous feed stream (1) is cooled and partially condensed in the main heat exchanger (2) by indirect heat exchange with the process streams (15, 16, 18) before being directed to the gas / liquid cryogenic separator (3). The overhead vapor stream (4) removed from the top of the gas / liquid cryogenic separator (3) is expanded, for example, in a turboexpander (5), and the expanded overhead vapor stream is then directed to the light components The lower area of the rectification column (LEFC) (7). The bottom liquid stream (8) removed from the gas / liquid cryogenic separator (3) is directed to the middle section of the heavy fraction fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com