Novel Fenton reaction device

A reaction device and a new type of technology, applied in the field of high-efficiency wastewater treatment devices, can solve the problems of reagent waste, reaction efficiency, large one-time dosage, complex reaction system, etc., and achieve the effects of easy popularization and application, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

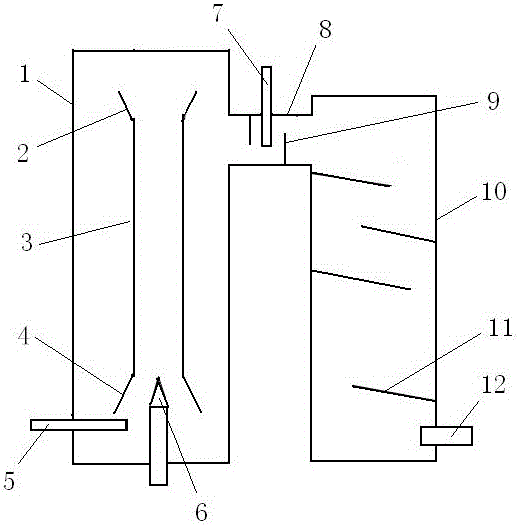

[0014] Reference figure 1 , The present invention provides a new type of Fenton-reactor, which is composed of a fully mixed flow reactor 1 and a plug flow reactor 10. Both the fully mixed flow reactor 1 and the plug flow reactor 10 are cylindrical structures with an upper part between them. The connecting pipe 8 of the fully mixed flow reactor 1 is connected, and the center of the fully mixed flow reactor 1 is built-in from the top to the bottom with a diversion mixing tube 3, and the diversion mixing tube 3 is fixed on the inner wall of the fully mixed flow reactor 1 by a fixing member. 3 has an inlet section 4 at the lower end and an outlet section 2 at the upper end. The water inlet spray port 6 extends from the bottom of the fully mixed flow reactor 1 upwards into the lower inlet section 4 of the diversion mixing pipe. There is drainage at the bottom of the flat plug flow reactor 10. Port 12, in the flat plug flow reactor 10, a baffle 11 is arranged from top to bottom betwe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap