Draught fan online monitoring system and method

A monitoring system and fan technology, applied in the direction of mechanical equipment, machine/engine, pump control, etc., can solve the problems of fan energy-saving effect reduction, regardless of other factors, etc., to achieve the effect of reducing losses, precise monitoring, and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0044] In the following description, many specific details are explained in order to fully understand the present invention. However, the present invention can be implemented in many other ways different from those described here, and those skilled in the art can make similar popularizations without violating the connotation of the present invention. Therefore, the present invention is not limited by the specific implementation disclosed below.

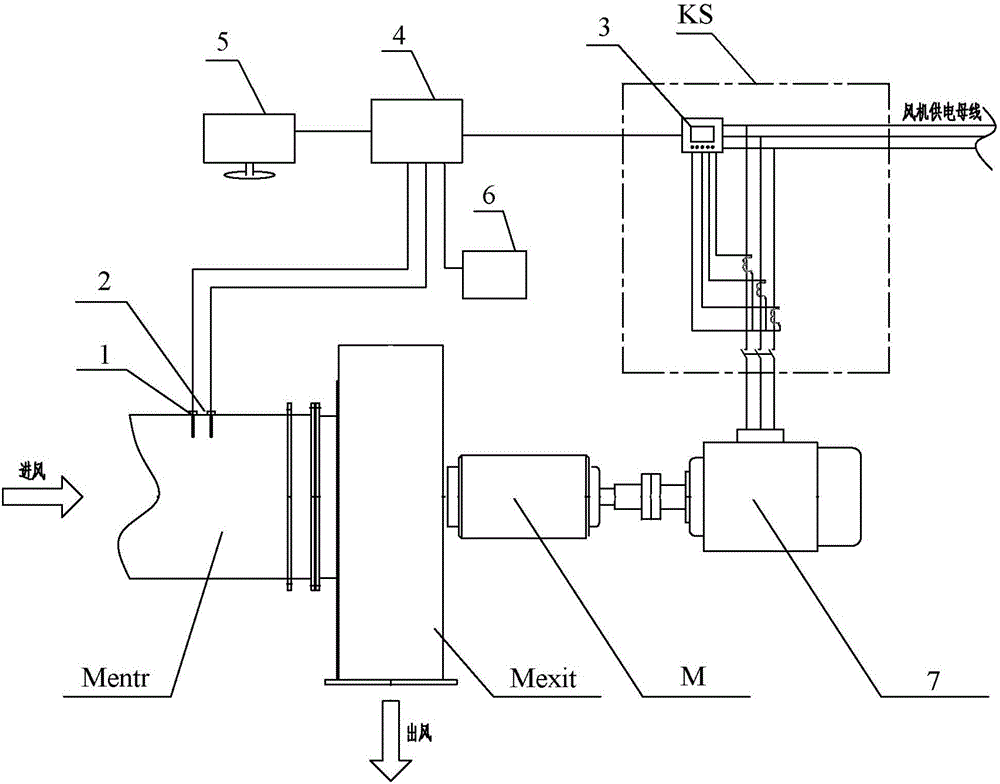

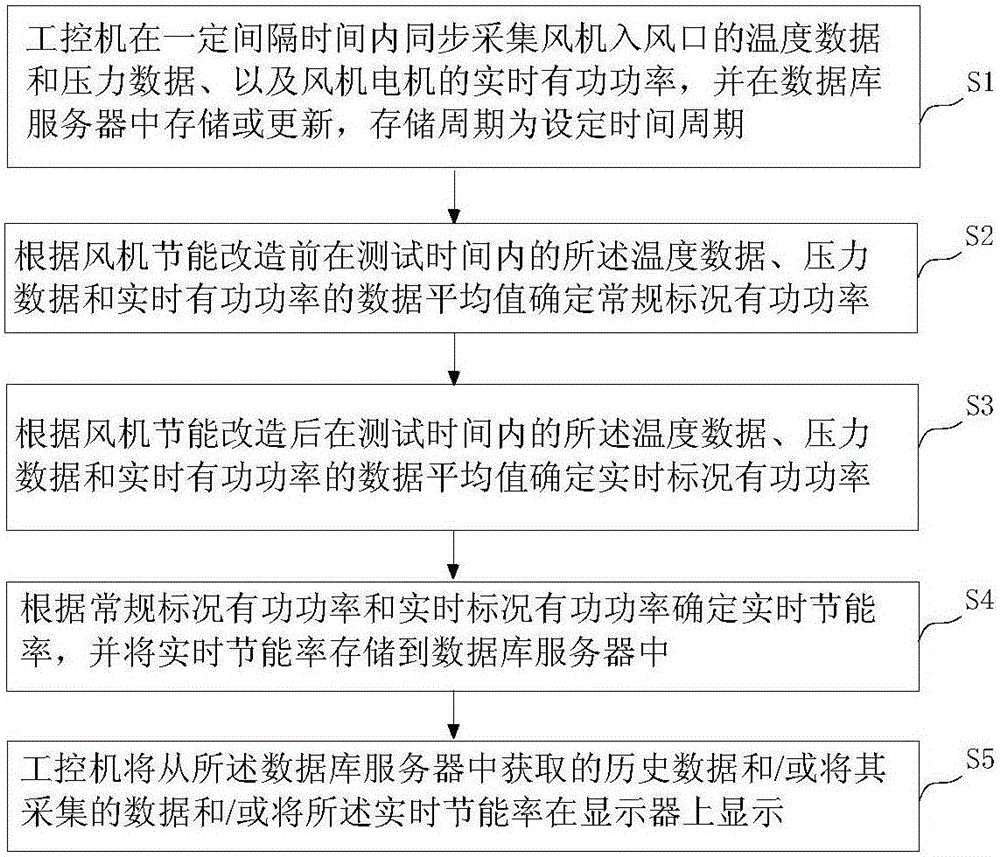

[0045] See figure 1 , The fan on-line monitoring system of the embodiment of the present invention includes a temperature sensor 1, a negative pressure sensor 2, a power meter device 3, an industrial computer 4, a display 5, and a database server 6.

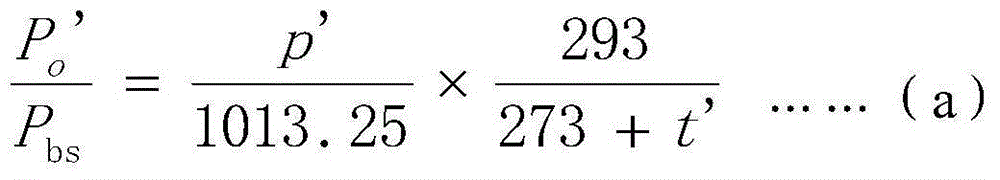

[0046] The temperature senso...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap