Manual Pulse Generator

A technology of manual pulse generation and angular position, which is applied in the direction of transmitting the sensing member by using an electric/magnetic device, which can solve the problems of early wear of the tooth portion, difficulty in obtaining durability, and difficulty in obtaining a sense of engagement, and achieves reliable performance. Engagement feeling, effect of suppressing tooth wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

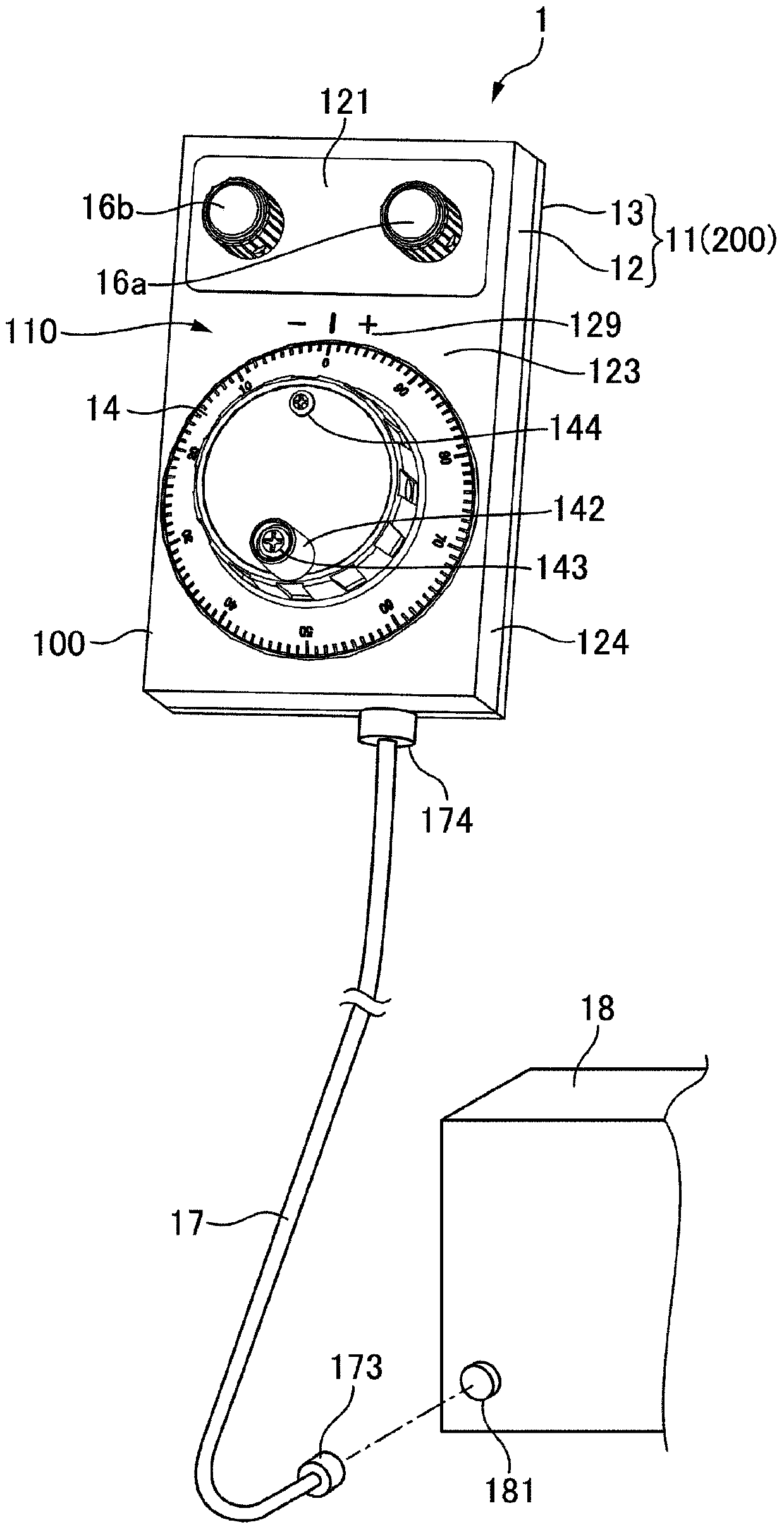

[0084] A manual pulse generator to which the present invention is applied will be described with reference to the drawings.

[0085] (The overall structure of the manual pulse generator)

[0086] figure 1 It is an explanatory diagram showing the appearance of the manual pulse generator 1 to which the present invention is applied. figure 2 It is an exploded perspective view of the manual pulse generator 1 to which the present invention is applied. In addition, in figure 2 Among others, in the direction in which the rotation center axis L of the rotating body 6 extends (rotation center axis L direction), the operation surface side is denoted as L1, and the back side is denoted as L2.

[0087] exist figure 1 as well as figure 2 In the illustrated manual pulse generator 1 , a dial 14 that is manually rotatable is provided on the front surface of the device body 100 , and marks 129 showing reference positions and polarities are marked around the dial 14 . The dial 14 const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com