Array substrate, manufacturing method thereof, liquid crystal display panel and display device

A technology for array substrates and base substrates, applied in optics, instruments, electrical components, etc., can solve problems such as complex manufacturing processes, achieve the effects of simplifying manufacturing processes, increasing aperture ratio, and reducing one-time patterning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

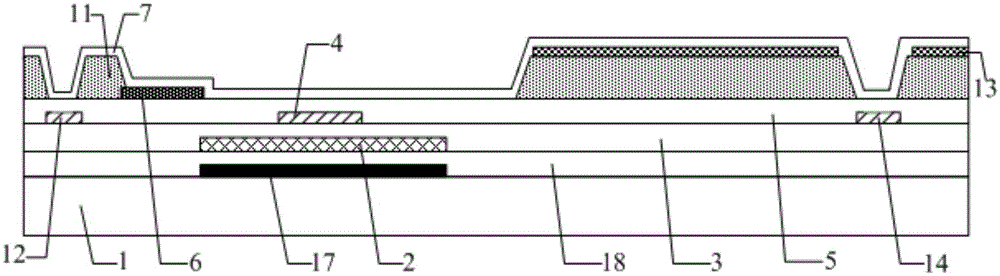

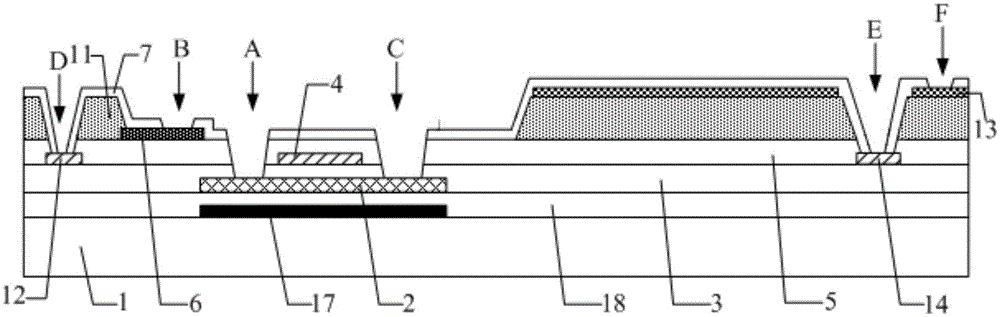

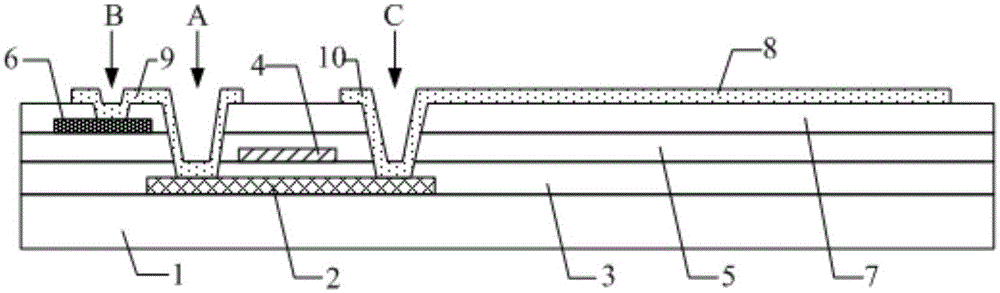

[0101] Example 1: Such as figure 2 The manufacturing method of the array substrate shown, such as Figure 7a-Figure 7m As shown, it can specifically include the following steps:

[0102] 1. Form a pattern including a light shielding layer 17 on the base substrate 1, such as Figure 7a Shown

[0103] 2. The buffer layer 18 is formed on the base substrate 1 with the pattern of the light shielding layer 17, such as Figure 7b Shown

[0104] 3. On the buffer layer 18, an amorphous silicon material is used to form the active layer film 19, and the active layer film 19 is subjected to an excimer laser annealing process, such as Figure 7c Shown

[0105] 4. Perform a patterning process on the active layer film 19 after the excimer laser annealing process to form a pattern including the active layer 2, such as Figure 7d Shown

[0106] 5. A gate insulating layer 3 is formed on the base substrate 1 on which the pattern of the active layer 2 is formed, such as Figure 7e Shown

[0107] 6. Form a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap