Fiber laser with high-efficiency temperature control device

A technology of fiber lasers and temperature control devices, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as loss of heat dissipation, stop working, laser stop working, etc., to solve applicability problems, improve work efficiency, The effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

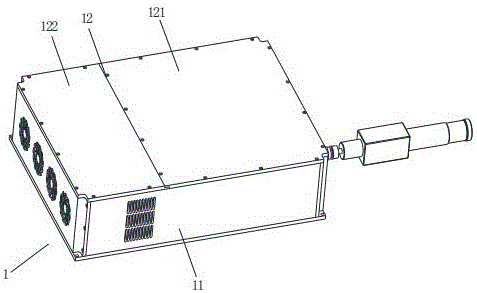

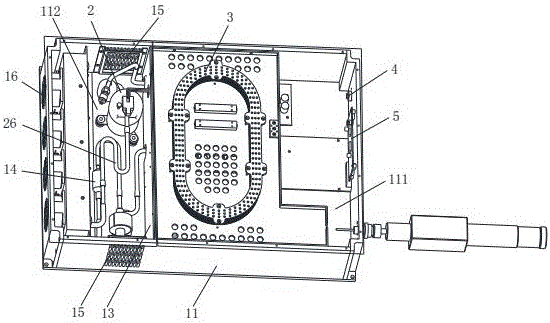

[0104] like Figure 1 to Figure 12 As shown, the fiber laser with high-efficiency temperature control device of the present invention includes a case 1 and a micro compressor direct cooling system 2 , an optical system 3 , a circuit system 4 and a control system 5 accommodated in the case 1 .

[0105] Chassis 1 is a separate laser chassis, such as figure 1 , figure 2 As shown, it includes a box 11, a box cover 12, a partition 13 and a screen filter 14; the partition 13 is assembled in the box 11, and divides the built-in space of the cabinet 1 into an optical circuit section 111 and a heat dissipation section 112; the box plate of the heat dissipation section 112 is provided with an air inlet channel 15 and an air outlet channel 16 to dissipate heat by convection with the external ambient air; the screen filter 14 is arranged on the air inlet channel 15 of the heat dissipation section 112 to isolate the air Ingress of sundries during convection;

[0106]The box body cover ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap