a mulberry picking machine

A technology of mulberry leaves and thorns, applied in the field of automatic leaf picking equipment, can solve the problems of not being suitable for collecting mulberry leaves in stages, not being able to adapt to complex land conditions, promotion and use restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

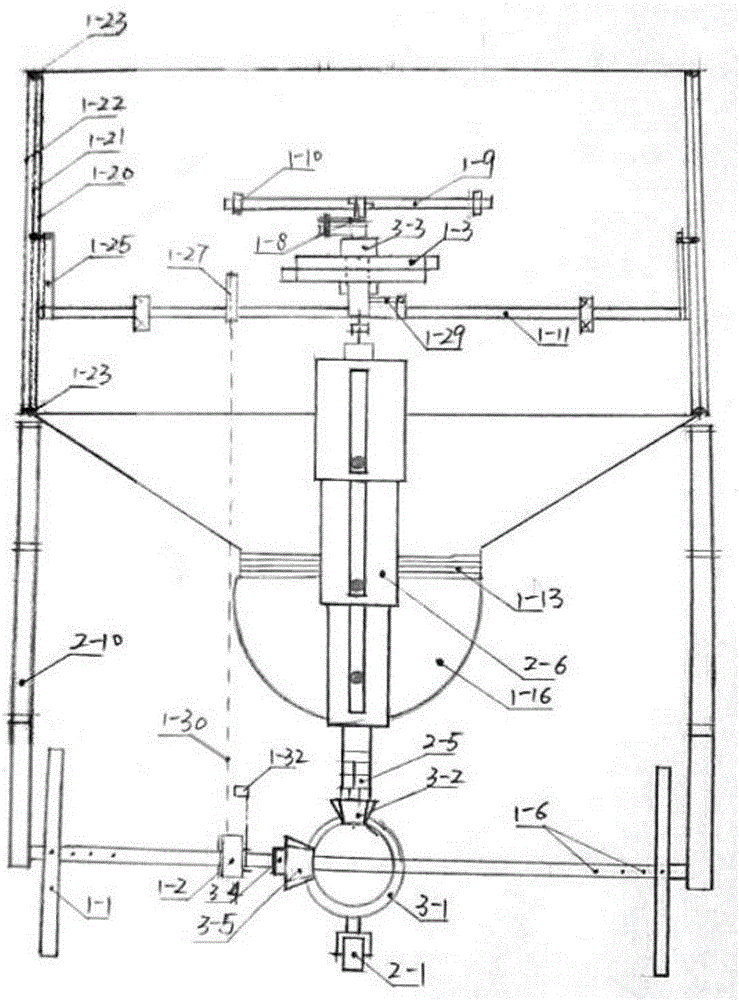

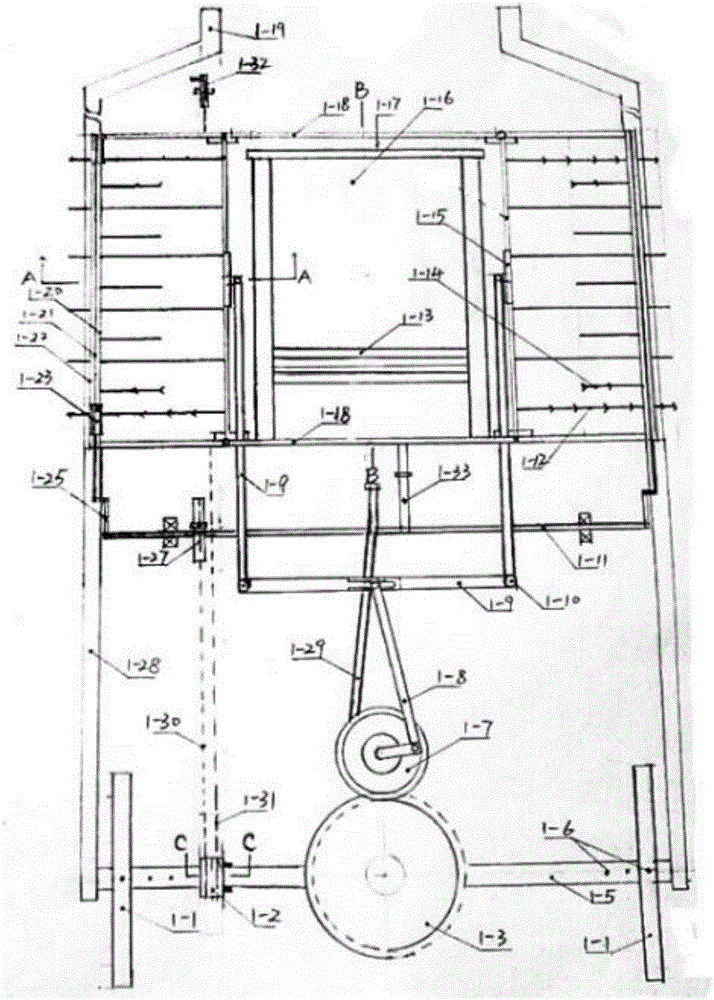

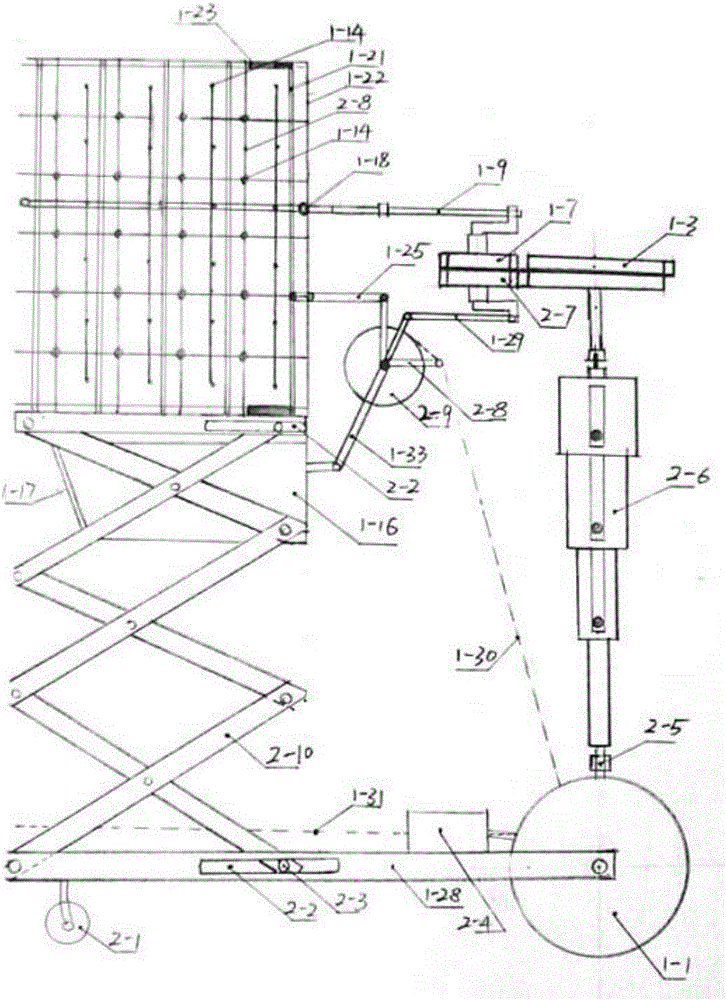

[0024] Such as figure 1 Shown, the working principle of the present invention is as follows: insert among the mulberry leaf clusters on the mulberry tree by the movable thorn bar frame 1-12 with barb, barb stabs into blade, and thorn bar pulls back blade and enters in the mulberry picker machine . Subsequently, the movable knife rest 1-21 that is arranged on both sides of the mulberry picking machine cooperates with the corresponding static knife rest 1-20 to cut off the petiole, and the mulberry leaves have just fallen into the storage groove 1-16 of the mulberry picking machine. The static knife rest 1-20 is provided with the non-return thruster 1-14 that prevents the blade from moving backwards to the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com