Automatic sundry removal material extrusion double-roller machine

A technology of squeezing rollers and counter-rollers, which is applied in the field of automatic impurity-removing material extruding and counter-rollers, can solve the problems of high cost, high processing cost, damage to milling equipment, etc., and achieves extended service life, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

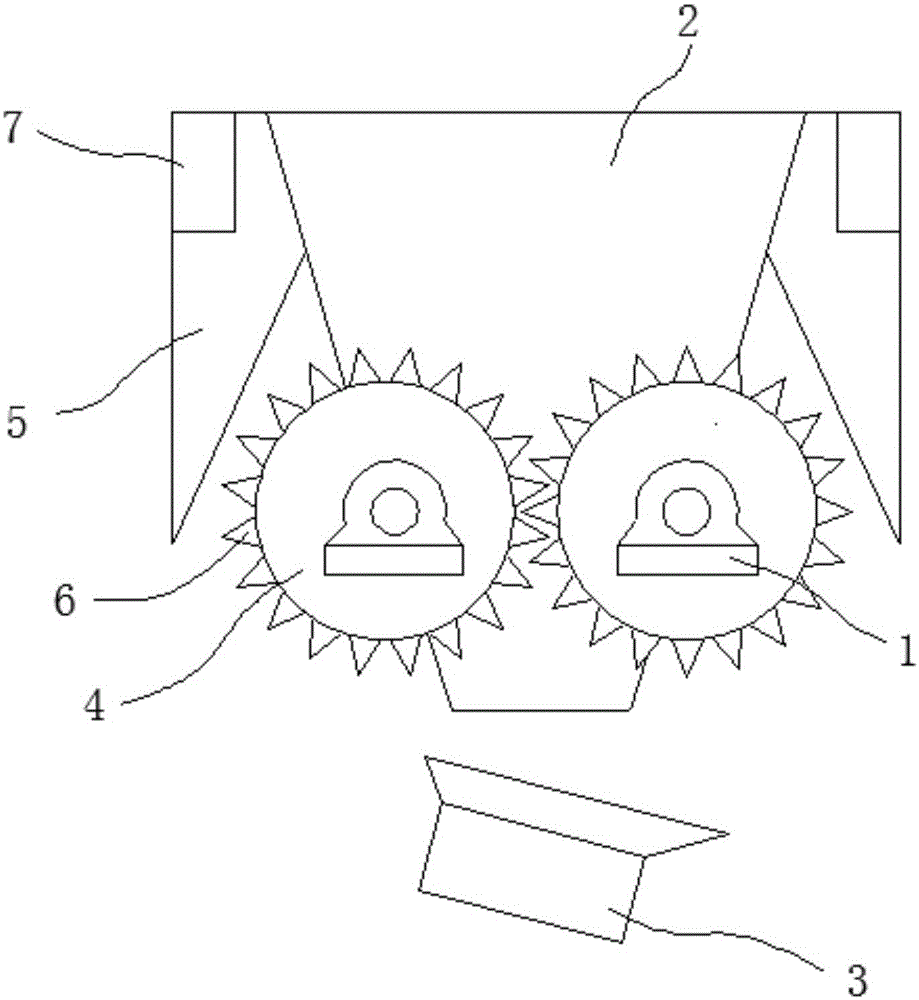

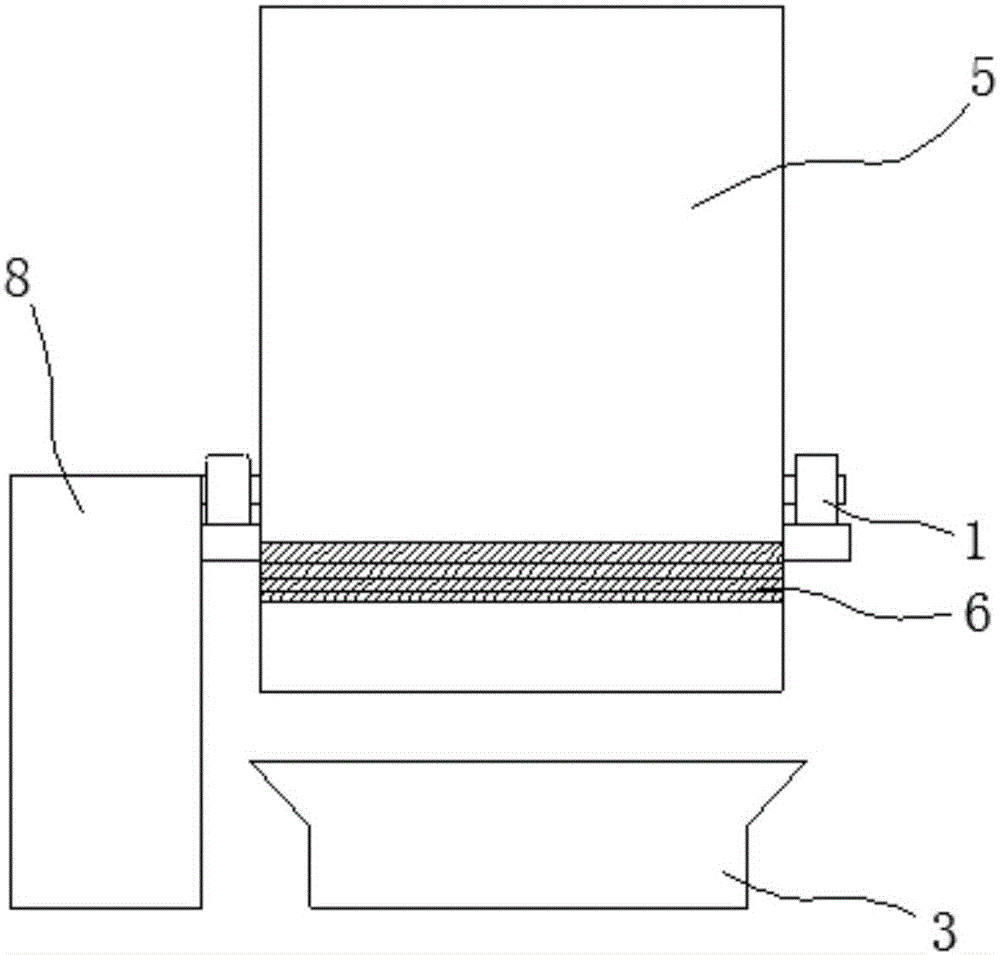

[0015] Such as figure 1 and figure 2 As shown, an automatic impurity-removing material extrusion double-roll machine includes a frame 1, a feed hopper 2, a material receiving hopper 3 and two extrusion rollers 4, and the material receiving hopper 3 is placed in the Below the feed hopper 2, the two squeeze rollers 4 are relatively rotatable embedded in the lower part of the feed hopper 2, and both ends of the two squeeze rollers 4 are connected to the frame 1 , the two extruding rollers 4 are cylindrical, and the surface of each extruding roller 4 is uniformly distributed with a plurality of extruding strips 6, each of which extruding strips 6 is welded on its extruded On the roller 4, the extruding bars 6 that ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap