Water tank of coffee machine and manufacturing method thereof

A manufacturing method and coffee machine technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of difficult mold forming, easy damage of the mold, high defective rate of water tanks, etc., achieve simple mold structure, improve yield rate, and obvious effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

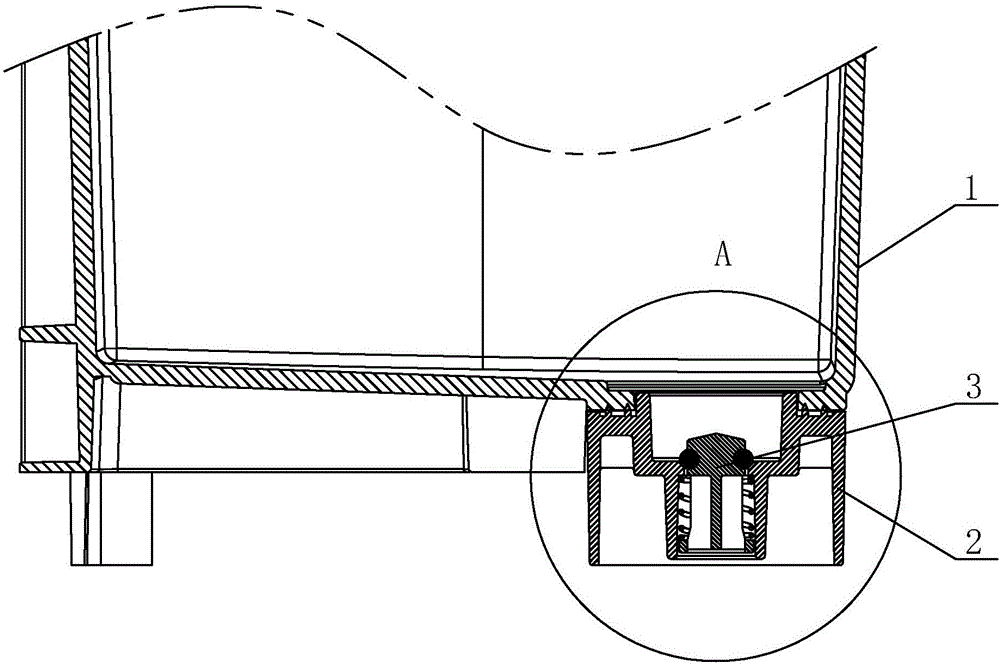

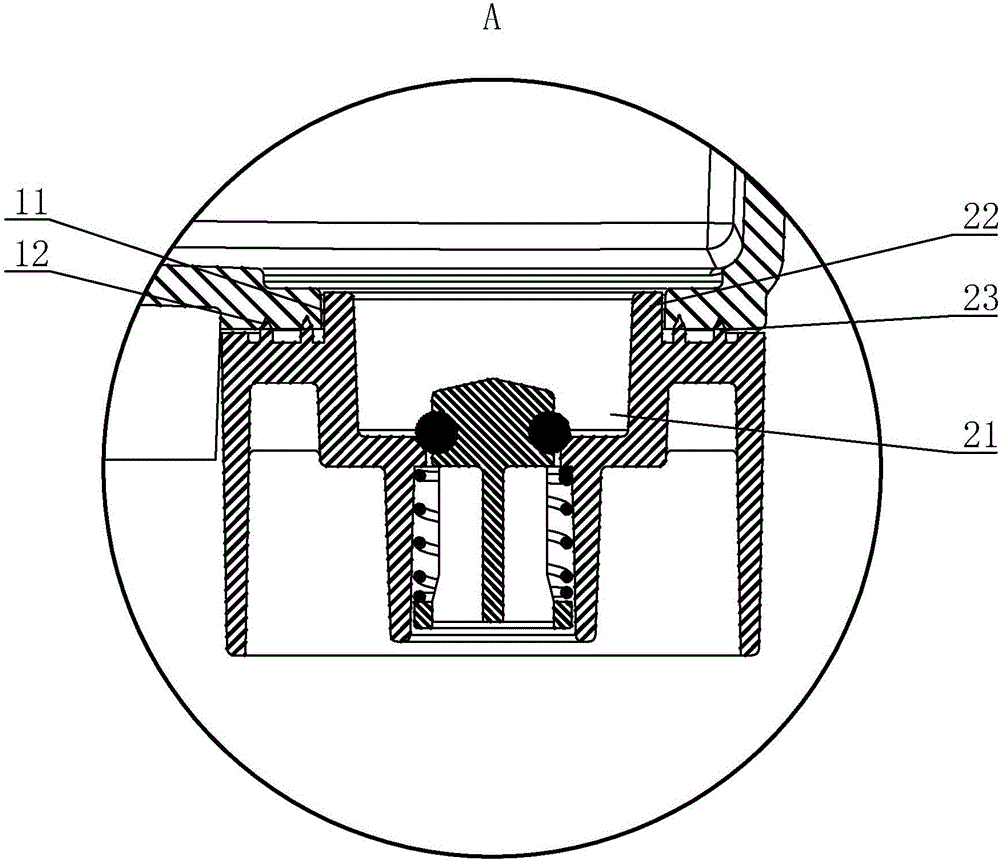

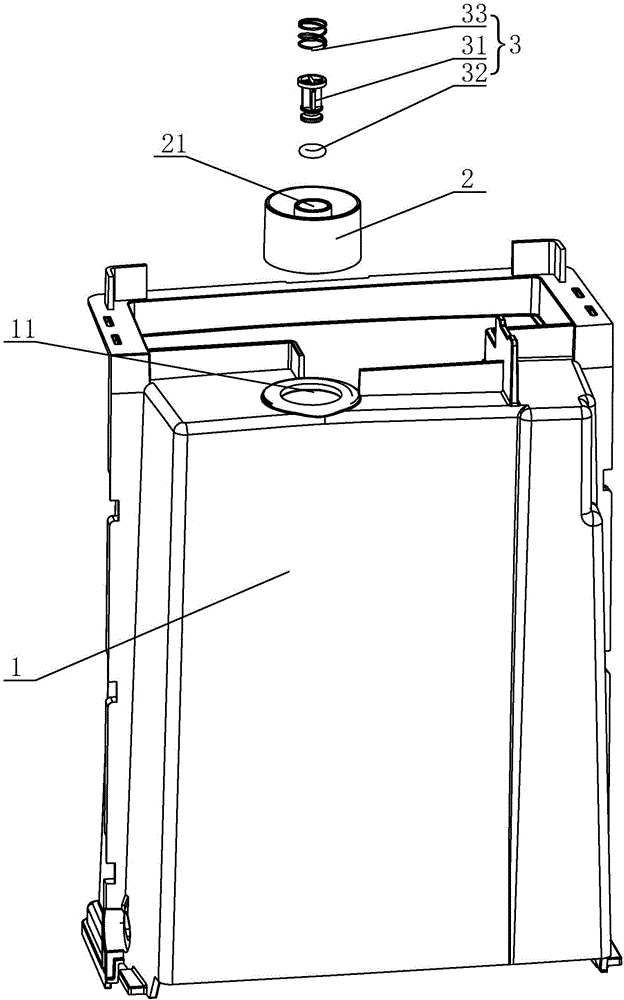

[0025] Such as Figure 1 to Figure 3 As shown, the water tank of a coffee machine according to the present invention includes a water tank 1, a water tank base 2 and a check valve assembly 3. The bottom of the water tank 1 is provided with a through hole 11, and the bottom of the water tank 1 has a plurality of tooth grooves 12. The water tank base 2 is located below the water tank 1. The water tank base 2 is provided with a stepped hole 21 connected to the outside. The stepped hole 21 is also communicated with the through hole 11. The upper end surface of the water tank base 2 A flange 22 is formed around the upper end of the stepped hole 21. The upper part of the water tank base 2 has a plurality of raised serrations 23 on the periphery of the flange 22. The water tank 1 is butted with the water tank base 2, and the flange 22 Extending into the through hole 11 of the water tank 1, the serrations 23 are embedded in the tooth groove 12 and the water tank 1 and the water tank ba...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap