Flue gas desulfurization and denitrification system

A technology for desulfurization and denitrification and flue gas, which is applied in the field of flue gas desulfurization and denitrification systems, can solve problems such as low denitrification efficiency, system scaling, and harm to human health, so as to facilitate equipment operation and maintenance, avoid scaling problems, and reduce equipment The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with embodiments and drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

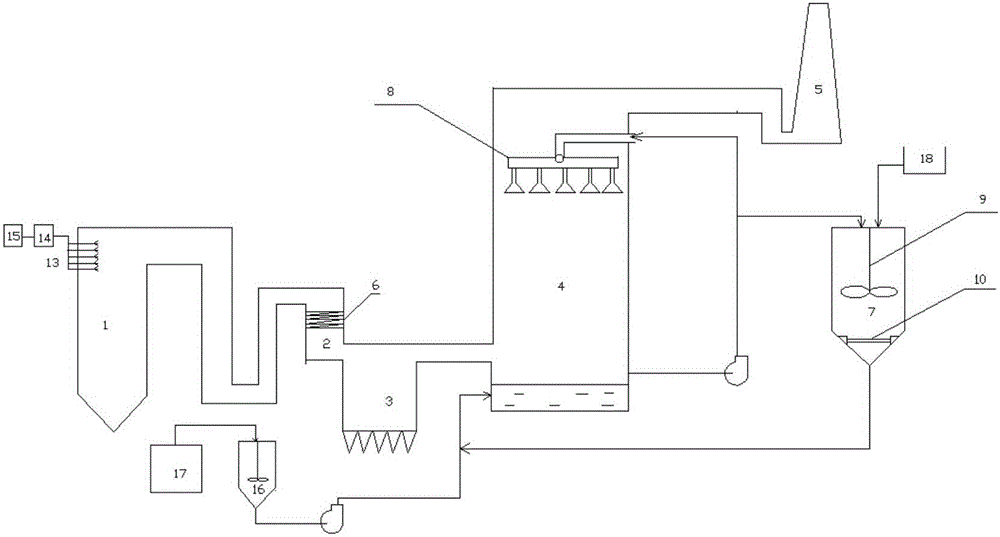

[0017] See figure 1 As shown, a flue gas desulfurization and denitrification system includes a coal-fired boiler 1, an SCR reactor 2, a dust collector 3, an absorption tower 4, and a chimney 5 connected in sequence through a flue gas pipeline. The furnace of the coal-fired boiler 1 is connected to denitrification Reductant injection module, the SCR reactor 2 is provided with a denitration catalyst layer 6; the lower part of the absorption tower is provided with an lye inlet and a lye outlet, and the lye outlet is respectively fed to the regeneration reactor 7 The outlet and the spray system 8 on the top are connected. The outlet of the regenerative reactor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap