Bag-feeding mechanism and control method of bag-feeding packaging machine, and bag-feeding packaging machine

A packaging machine and bag feeding technology, applied in packaging and other directions, can solve the problems of occupying the space of prefabricated bags, high technical requirements of workers, and reducing production efficiency, so as to reduce the labor intensity of workers, operate simple and fast, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

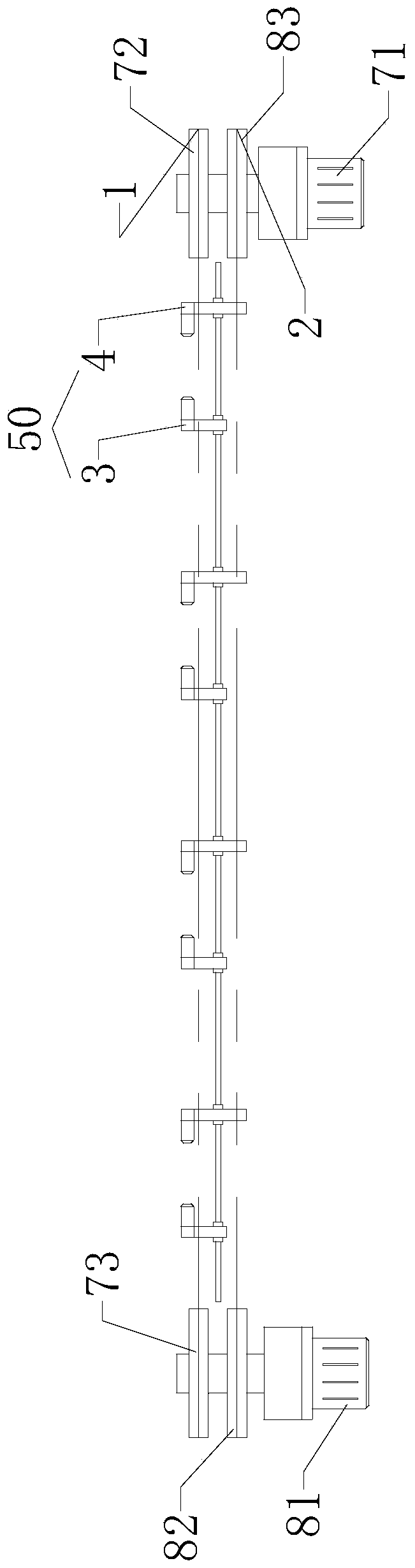

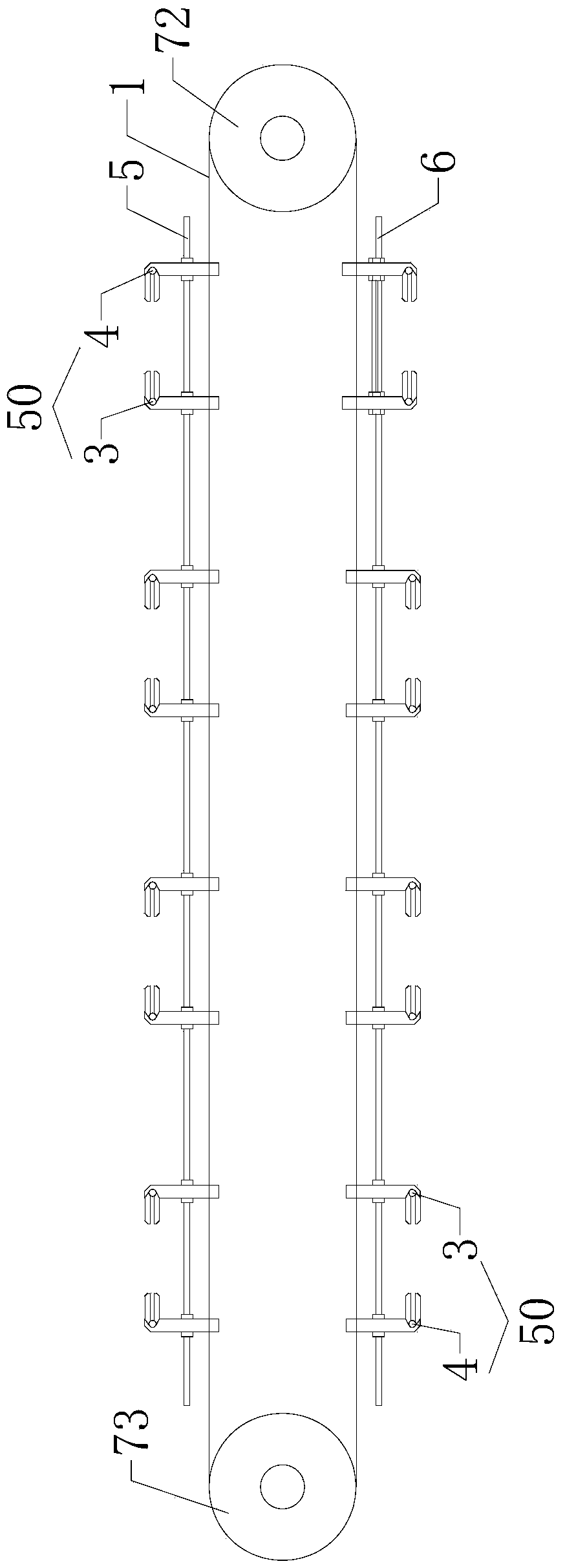

[0025] combine figure 1 and figure 2 , a bag-feeding mechanism applied to a bag-feeding packaging machine, comprising a first drive mechanism, a second drive mechanism, a first endless conveyor belt 1 driven by the first drive mechanism, and a second drive mechanism driven by the second drive mechanism. The endless conveyor belt 2; the first endless conveyor belt 1 and the second endless conveyor belt 2 are all horizontally arranged and both up and down are relatively arranged, the first endless conveyor belt 1 is connected with a plurality of first grippers 3, and the second endless conveyor belt 2 is connected with The plurality of second holders 4 corresponding to the plurality of first holders 3 one-to-one, the corresponding first holders 3 and the second holders 4 form a bag holder device 50 .

[0026] The control method of the above-mentioned bag feeding mechanism comprises the following steps:

[0027] 1) Control the operation of the first drive mechanism and the sec...

Embodiment 2

[0039] combine Figure 1 to Figure 4 , a bag-feeding packaging machine, comprising a frame 10 and several packaging mechanisms located on the frame 10 (several packaging mechanisms are respectively located at different stations), a finished product delivery system for transporting finished products that have been packaged Mechanism; also includes the bag feeding mechanism described in Embodiment 1, the bag feeding mechanism is arranged on the frame 10, and several packaging mechanisms are arranged side by side and located on one side of the first endless conveyor belt 1 of the bag feeding mechanism.

[0040] The above-mentioned several packaging mechanisms include a prefabricated bag transfer mechanism 11, a blanking mechanism 12, a pre-sealing mechanism 13, and a shaping and sealing mechanism 14 arranged in sequence.

[0041] The prefabricated bag transfer mechanism 11 is used for placing the prefabricated bag, and grabbing the prefabricated bag and placing it on the bag hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com