Preparation method of carbon nanotube composite wire

A carbon nanotube composite, carbon nanotube technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve problems such as weak carbon nanotube binding force, achieve enhanced mechanical strength, enhanced van der Waals force, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

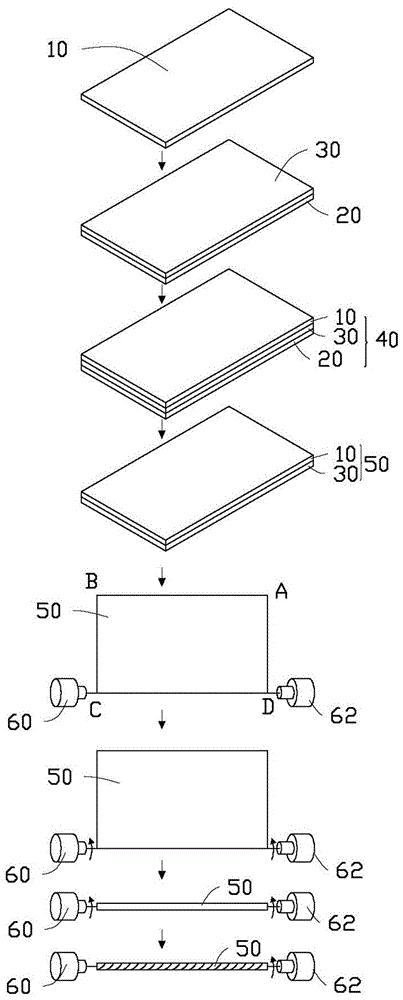

[0023] See figure 1 , the embodiment of the present invention provides a method for preparing a carbon nanotube composite wire 80, comprising the following steps:

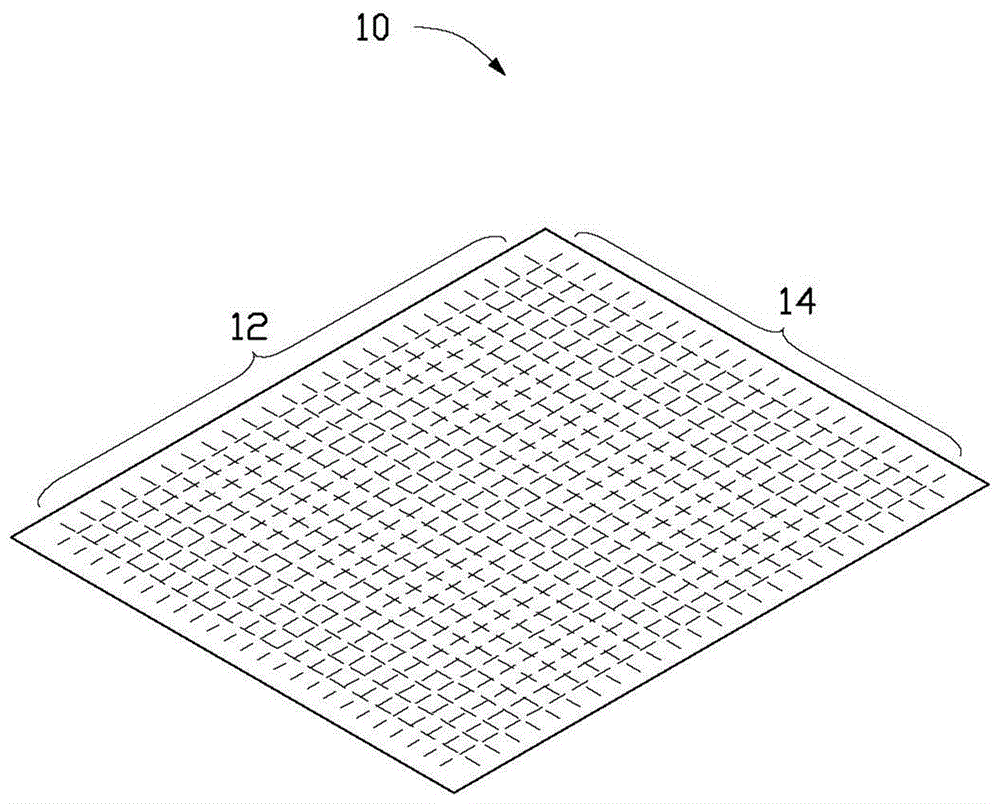

[0024] S10, providing at least one carbon nanotube film 10;

[0025] S20, providing a substrate 20 on which a graphene film 30 is grown;

[0026] S30, attaching the carbon nanotube film 10 to the surface of the graphene film 30 away from the substrate 20 to form a composite structure 40;

[0027] S40, removing the substrate 20 to form a carbon nanotube-graphene composite film 50;

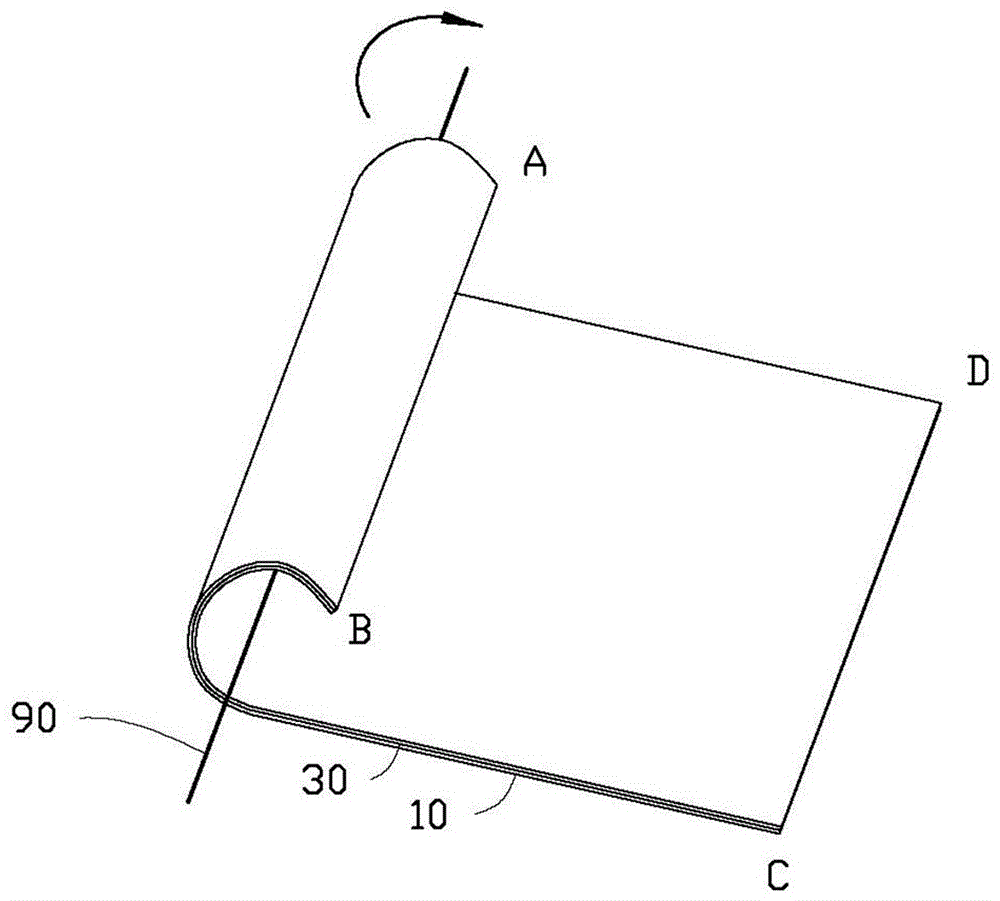

[0028] S50 , rolling up and twisting the carbon nanotube-graphene composite film 50 to form a carbon nanotube composite wire 80 .

[0029] In step S10, the carbon nanotube film 10 includes a plurality of uniformly distributed carbon nanotubes. The carbon nanotubes can be one or more of single-wall carbon nanotubes, double-wall carbon nanotubes, and multi-wall carbon nanotubes. The carbon nanotubes in the carbon nanotube film 10 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com