Multilayered graphene stain positioning detection device

A technology for positioning detection devices and olefinic stains, which is applied in the direction of optical testing flaws/defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

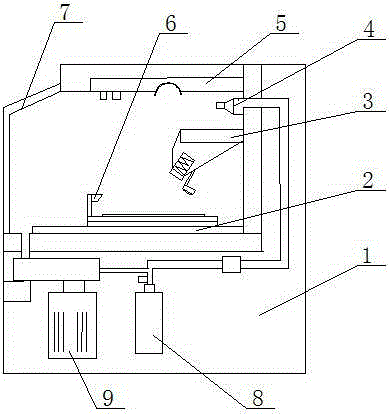

[0057] Such as figure 1 As shown, a kind of multi-layer graphene spot detection device of the present invention comprises: frame 1 and the scanning mechanism 5 that is arranged on frame 1, controller, operating mechanism, photographing mechanism 3, image processor, sealing cover 7. Air blower and vacuum pump;

[0058] The scanning mechanism 5 includes a scanning frame and a laser device and a lifter fixed on the scanning frame. The laser device includes a flat laser generator, a round head laser generator and a concave laser receiving groove, and several laser sensors are arranged on the inside of the laser receiving groove; The laser sensor, the two laser generators and the lifter are respectively electrically connected to the controller;

[0059] The operating mechanism includes a mobile platform 2 and a fixer, a reflector and a light screen 6 arranged on the mobile platform 2. The mobile platform 2 is provided with a lateral mover and a vertical mover, and the mobile platf...

specific Embodiment 2

[0073] According to the control system of the multilayer graphene stain location detection device of embodiment 1, comprising:

[0074] control units, including controllers;

[0075] Scanning unit, comprises scanning mechanism 5, and scanning mechanism 5 comprises laser device, lifter, and laser device comprises a flat laser generator, a round head laser generator and concave laser receiving groove, and is located at some laser sensors inside the laser receiving groove ; After the laser lifts to the specified position, the ribbon laser produces a flat laser with a width of 1mm and a thickness of 10um. The laser is reflected by the graphene and is received by the laser sensor in the specified area in the laser receiving slot; When the laser intensity change received by the laser or the laser sensor in the designated area exceeds the set value, the round head laser generator is turned on to generate a cylindrical laser with a radius of 10um. The cylindrical laser scans along the...

specific Embodiment 3

[0083] The photographing method of the control system according to specific embodiment 2:

[0084] Further, the camera method of the control system:

[0085] (1) After the control unit marks the stain position, turn on the light screen and camera; adjust the position of the light screen and camera so that the camera is aligned with the graphene stain position, and the light screen reflected by the mirror is used as the background;

[0086] (2) Adjust the telescopic device and control the movement of the magnifying glass to make the camera focus on the stain position;

[0087] (3) Adjust the light screen to a white screen, and the camera takes continuous pictures of the stain position at intervals of 0.1ms; obtain 20-30 pictures;

[0088] (4) The camera unit transfers the acquired photos to the control unit, and the control unit performs judgment and processing;

[0089] (5) Adjust the color of the light screen for more than three times, and take pictures of the stain positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com