Manual press

A technology of presses and machine bases, applied in the directions of presses, punching machines, manufacturing tools, etc., can solve the problems of inconvenient operation of workers, reduce production efficiency, affect the progress of other operations, etc., and achieve the effect of ensuring product quality and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

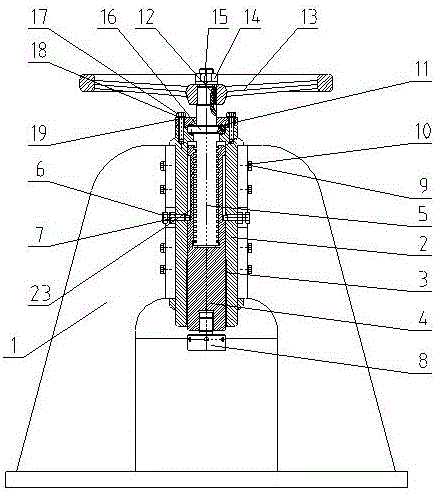

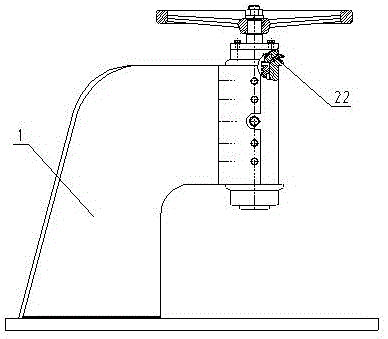

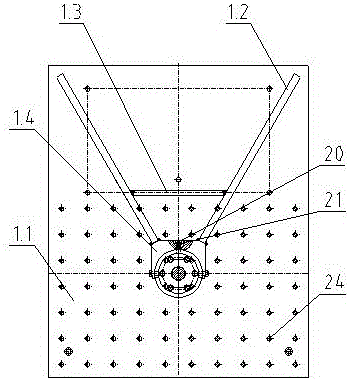

[0043] see Figure 1~Figure 3 , a manual press machine of the present invention, it comprises machine base 1, and described machine base 1 is provided with installation cylinder 2 through second bolt 9 and first washer 10, and described installation cylinder 2 is provided with push column 4, so The lower end of the top column 4 is provided with a pressure head 8, a sliding bearing 3 is provided between the top column 4 and the installation cylinder 2, and a step is provided on the top of the installation cylinder 2, and a square screw 5 is placed on the step, so that The middle part of the square tooth screw 5 is provided with an annular boss 16, and the annular boss 16 is arranged in the step. and the second gasket 15 are provided with a handwheel 13, the handwheel 13 is connected with the square tooth screw 5 through a flat key 12, and an end cover 19 is arranged above the top column 4, and the end cover 19 passes through the third The bolt 17 and the third washer 18 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com