Method for degrading carmine

A carmine and hydrogen peroxide technology, which is applied in textile industry wastewater treatment, oxidized water/sewage treatment, etc., can solve the problems of hydrogen peroxide waste, low utilization rate, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

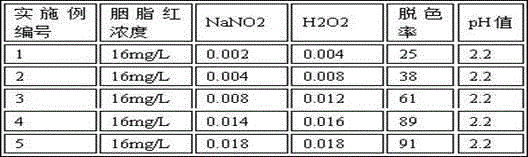

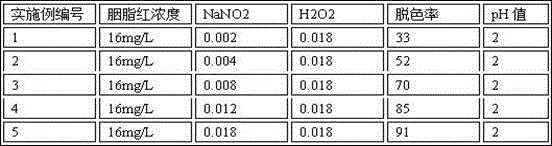

[0025] When the carmine concentration is 16mg / L, different concentrations of NaNO 2 And H 2 O 2 Influence on decolorization rate:

[0026] The following NaNO 2 And H 2 O 2 The concentration is molarity;

[0027] Table 1.1

[0028]

[0029] Table 1.2

[0030]

Embodiment 2

[0032] When the carmine concentration is different, the different concentration of NaNO 2 The effect of hydrogen peroxide and hydrogen peroxide on the decolorization rate:

[0033] The following NaNO 2 And the concentration of hydrogen peroxide is molar concentration;

[0034] Table 2.1

[0035]

[0036] Table 2.2

[0037]

Embodiment 3

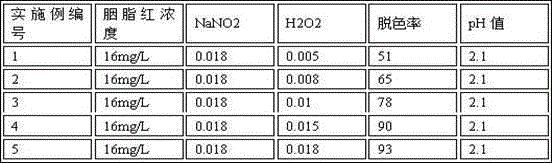

[0039] When the carmine concentration is 40mg / L, different concentrations of NaNO 2 The effect of hydrogen peroxide and hydrogen peroxide on the decolorization rate:

[0040] The following NaNO 2 And the concentration of hydrogen peroxide is molar concentration;

[0041] Form 3.1

[0042] Example number Carmine concentration NaNO2 H2O2 Decolorization rate pH value 1 40mg / L 0.030.005531.8 2 40mg / L 0.030.01691.9 3 40mg / L 0.030.015791.9 4 40mg / L 0.030.02881.9 5 40mg / L 0.030.025911.9

[0043] Table 3.2

[0044]

[0045] Through orthogonal experiment and single factor analysis experiment on carmine wastewater, the best experimental conditions for treating this printing and dyeing wastewater were determined. In NaNO 2 And H 2 O 2 When the molar concentration is 1:1 and the reaction time is 60s, the decolorization rate can reach more than 90%. Experiments show that the peroxynitrite system can efficiently degrade carmine wastewater. The above experiments prove that the system can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com