Tartarian buckwheat shell with formaldehyde-removing function and preparation method thereof

A technology of tartary buckwheat shell and function, applied in the field of tartary buckwheat shell with formaldehyde removal function and its preparation, can solve the problems of difficult carrier processing, unsuitable for wide use, and low catalytic efficiency, so as to improve photocatalytic efficiency and be suitable for industrialization The effect of simple production and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

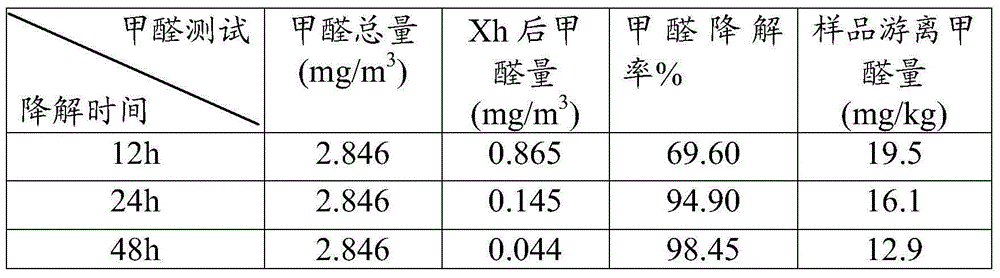

Examples

Embodiment 1

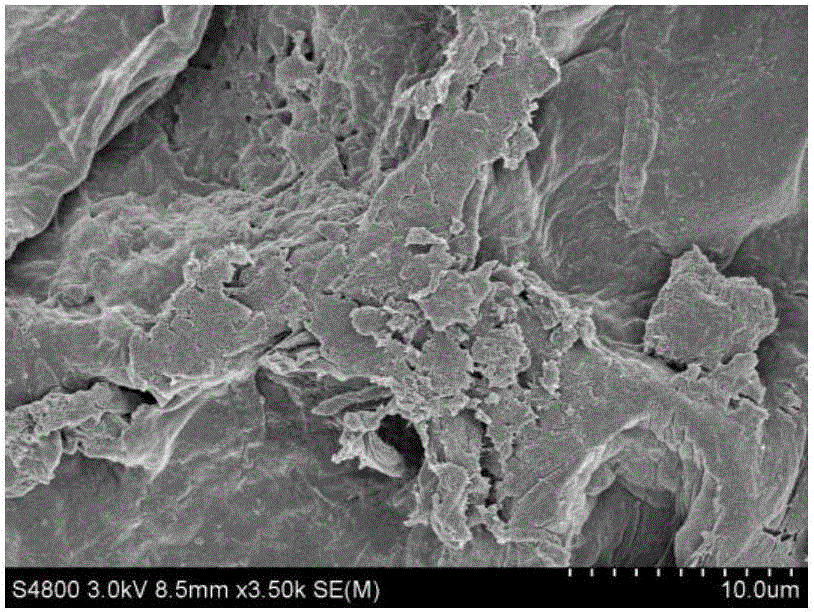

[0036] 1) Preparation of titanium dioxide gel by gel-sol method: drop 1 mL of phosphate-type gemini anionic surfactant into 100 mL of a 1% sericin solution, and adjust the pH to 1 with acetic acid to obtain solution A; add 10 mL of titanium dioxide Add tetrabutyl acid to 100 mL of absolute ethanol and mix to obtain solution B; under high-speed stirring, slowly drop solution B into solution A to form a dispersed colloid, and adjust the pH of the system to 6 with sodium carbonate aqueous solution , aged for 12h to obtain nano-titania gel;

[0037] 2) the metal pretreatment of tartary buckwheat hulls: 10g tartary buckwheat hulls are dipped in the palladium nitrate aqueous solution of 100ppm at 100mL concentration for 30min, then dehydrated and dried, so far palladium ions are attached to the tartary buckwheat hull surface;

[0038] 3) Dilute 10 mL of nano-titanium dioxide gel by 10 times, and immerse the tartary buckwheat husks pretreated in step 2) into it, the immersion tempera...

Embodiment 2

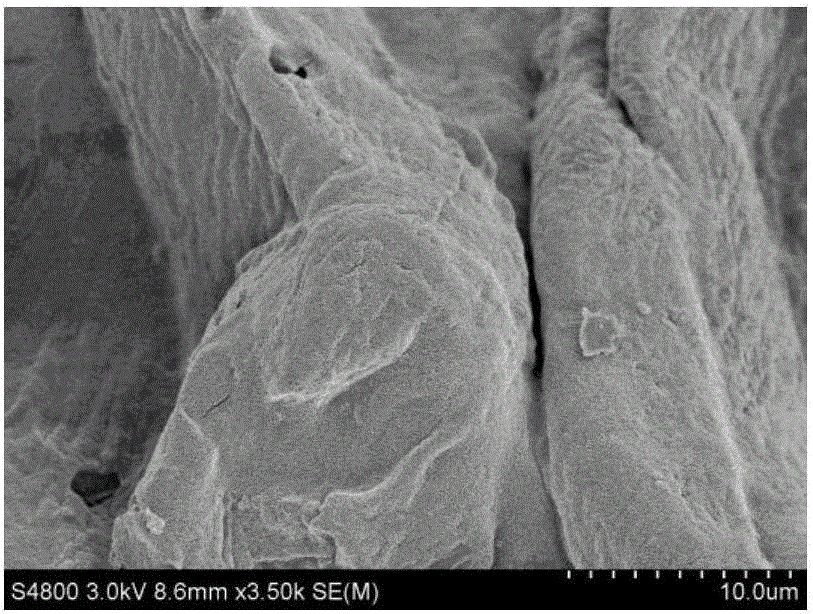

[0046]1) Preparation of titanium dioxide gel by gel-sol method: drop 1 mL of polysorbate surfactant into 100 mL of a 1% polyvinylpyrrolidone solution, and adjust the pH to 1.5 with citric acid to obtain solution A; Tetrabutyl acid was added to 100 mL of anhydrous ethanol and mixed to obtain solution B; in the state of high-speed stirring, slowly drop solution B into solution A to form a dispersed colloid, and adjust the pH of the system with aqueous sodium bicarbonate solution to 6. Ageing for 12h to obtain nano titanium dioxide gel;

[0047] 2) metal pretreatment of tartary buckwheat hulls: 10 g of tartary buckwheat hulls were dipped in 100 mL of a platinum nitrate aqueous solution with a concentration of 100 ppm for 30 min, and then dehydrated and dried, so that platinum ions were attached to the surface of tartary buckwheat hulls;

[0048] 3) Dilute 10 mL of nano-titanium dioxide gel by 10 times, and immerse the tartary buckwheat husks pretreated in step 2) in it, at a temp...

Embodiment 3

[0051] 1) Preparation of titanium dioxide gel by gel-sol method: drop 1 mL of fatty alcohol polyoxyethylene ether type surfactant into 100 mL of chitosan solution with a concentration of 1%, adjust the pH value to 1 with acetic acid, and obtain solution A; Add 10 mL of tetrabutyl titanate to 100 mL of absolute ethanol and mix to obtain solution B; under high-speed stirring, slowly drop solution B into solution A to form a dispersed colloid, and adjust the pH of the system with sodium carbonate aqueous solution To 6, aging for 12h to obtain nano titanium dioxide gel;

[0052] 2) metal pretreatment of tartary buckwheat hulls: 10g of tartary buckwheat hulls are immersed in 100mL concentration of silver nitrate aqueous solution of 100ppm for 30min, then dehydrated and dried, so far silver ions are attached to the surface of tartary buckwheat hulls;

[0053] 3) Dilute 10 mL of nano-titanium dioxide gel by 10 times, and immerse the tartary buckwheat husks pretreated in step 2) into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com