A process and equipment for removing nitrate in drinking water

A nitrate and drinking water technology, applied in water pollutants, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc., can solve the problem of reduced removal rate, high resin removal rate, increased equipment investment and cost, etc. problem, to achieve the effect of low cost, less resin dosage, stable and balanced water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

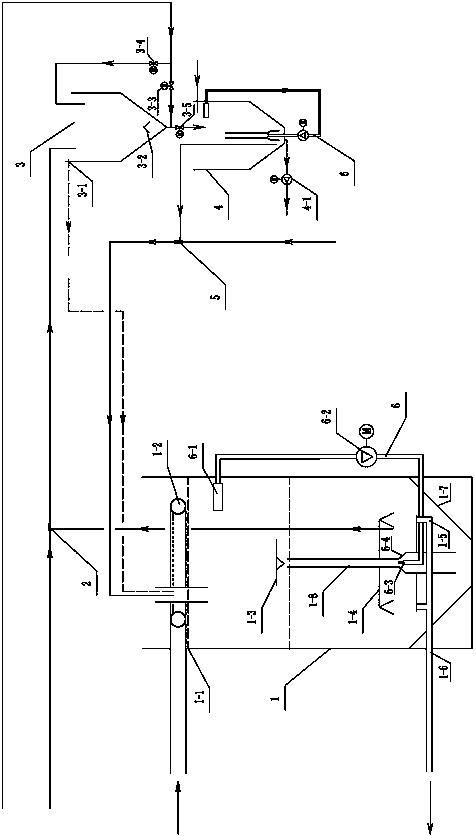

[0026] Please refer to the attached figure 1 As shown, the present invention relates to a kind of equipment for removing nitrate in drinking water, which consists of a reaction tank 1, a resin extractor 2, a resin temporary storage tank 3, a resin regeneration tank 4, a resin injector 5 and two hydraulic agitators 6 And so on several parts.

[0027] Wherein, the reaction tank 1 is provided with a water inlet 1-1 and a water outlet 1-6. The reaction tank 1 is connected with one of the hydraulic stirrers 6 . A central pipe 1-8 is vertically arranged in the center of the reaction tank 1, with a bell mouth 6-4 and a spray port 6-3 inside, and a water pump 6-2 outside. The resin extractor 2 extends to the bottom of the reaction tank 1 , which can extract the resin and transport it to the temporary resin storage tank 3 . The top side wall of the temporary resin storage tank 3 is provided with an overflow hole 3-1, and the overflowed water and resin are injected into the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com