Method for preparing CNTs/Ni composite material through composite electrodeposition

A composite electrodeposition and composite material technology, applied in the field of composite electrodeposition to prepare composite materials, can solve problems such as poor dispersion of carbon nanotubes, and achieve the effects of wide applicability, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

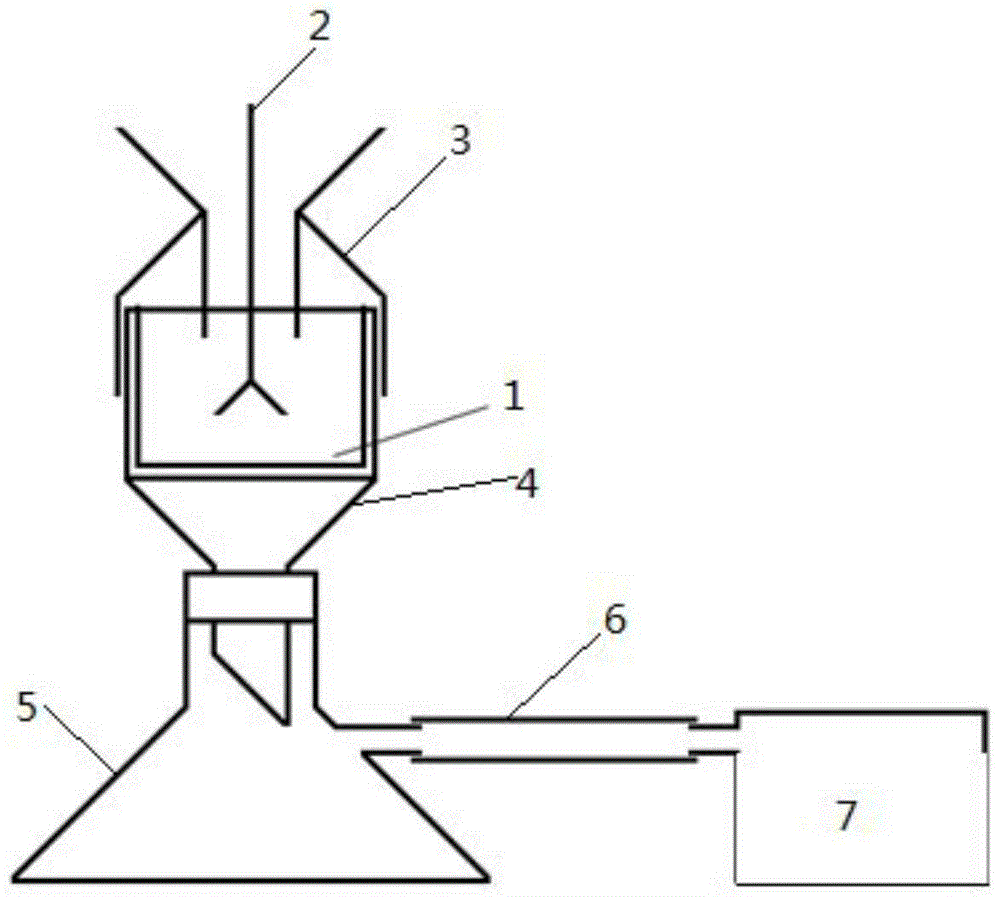

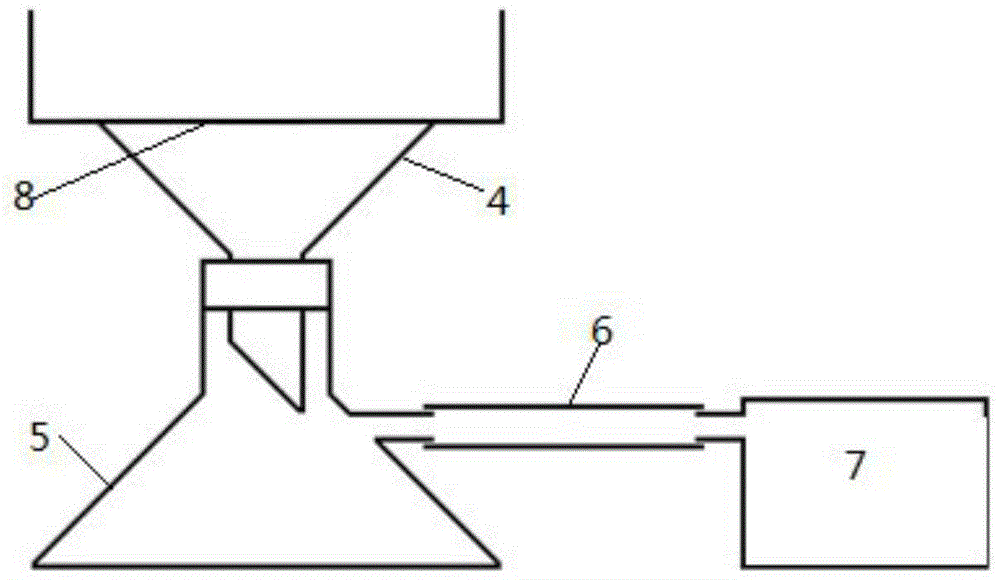

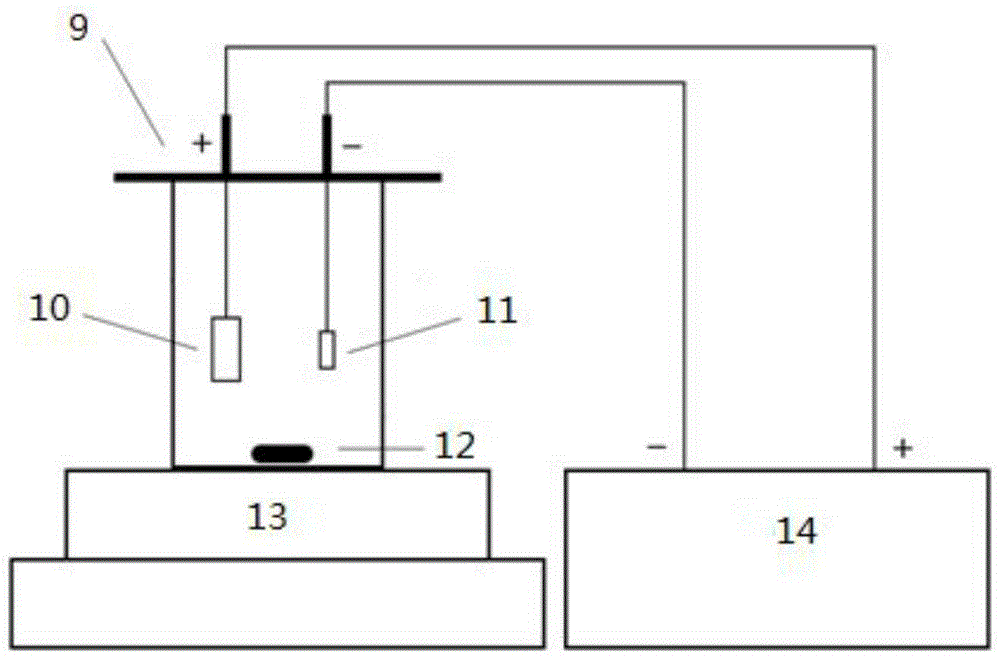

Method used

Image

Examples

Example Embodiment

[0026] Specific embodiment 1: This embodiment is a method for preparing CNTs / Ni composite material by composite electrodeposition, which is specifically carried out according to the following steps:

[0027] 1. Mix the carbon nanotube powder with concentrated nitric acid, add concentrated sulfuric acid, and then perform intermittent ultrasonic treatment for 25h under mechanical stirring conditions, each ultrasonic time is 30min, the intermittent time is 2h, and the suspension is obtained; The tube powder is 15g, the volume of concentrated nitric acid is 250mL, and the volume of concentrated sulfuric acid is 750mL;

[0028] 2. Add distilled water to the suspension obtained in step 1, until the volume is 2000mL, stir evenly, and then stand still to produce a precipitate. When the volume of the precipitate reaches 1000mL, pour the upper solution; repeat the operation: add distilled water to the volume 2000mL, stir evenly, and then stand to produce a precipitate. When the volume of the...

Example Embodiment

[0032] Specific embodiment two: This embodiment is different from the specific embodiment one in that the mass concentration of concentrated nitric acid in step one is 69%. Others are the same as the first embodiment.

Example Embodiment

[0033] Specific embodiment three: this embodiment is different from specific embodiment one or two in that the mass concentration of concentrated sulfuric acid in step one is 98%. Others are the same as the first or second embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap