Manufacturing method for inductor through two times of powder feeding and structure of inductor

A technology of secondary powder feeding and production method, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., and can solve problems such as decreased powder filling accuracy, uneven metal powder amount, and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

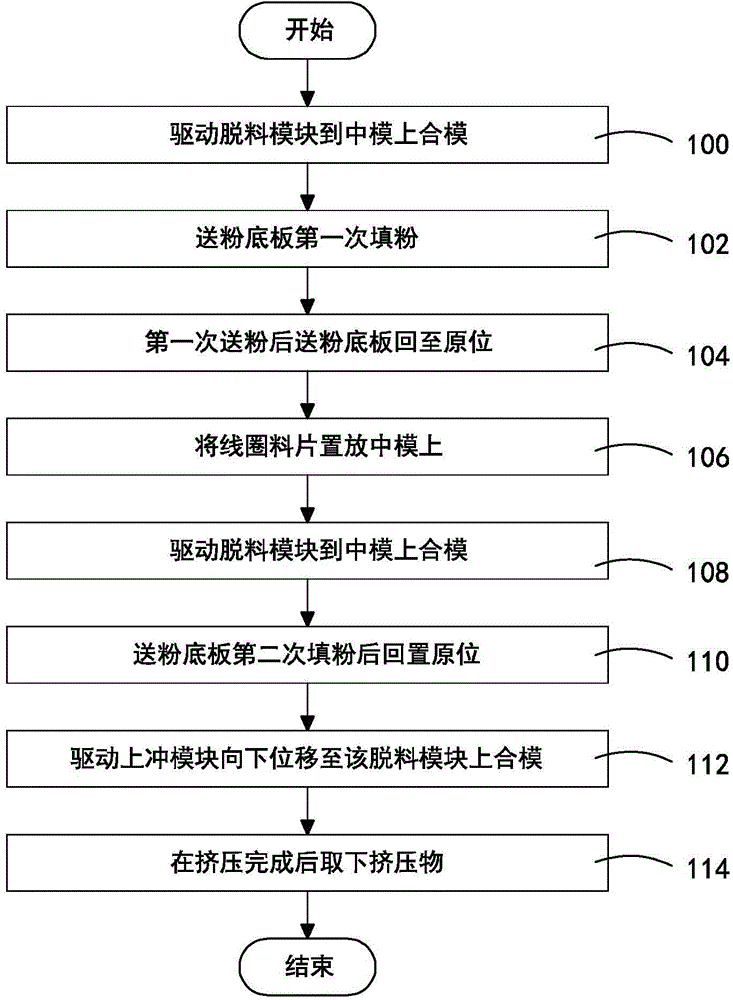

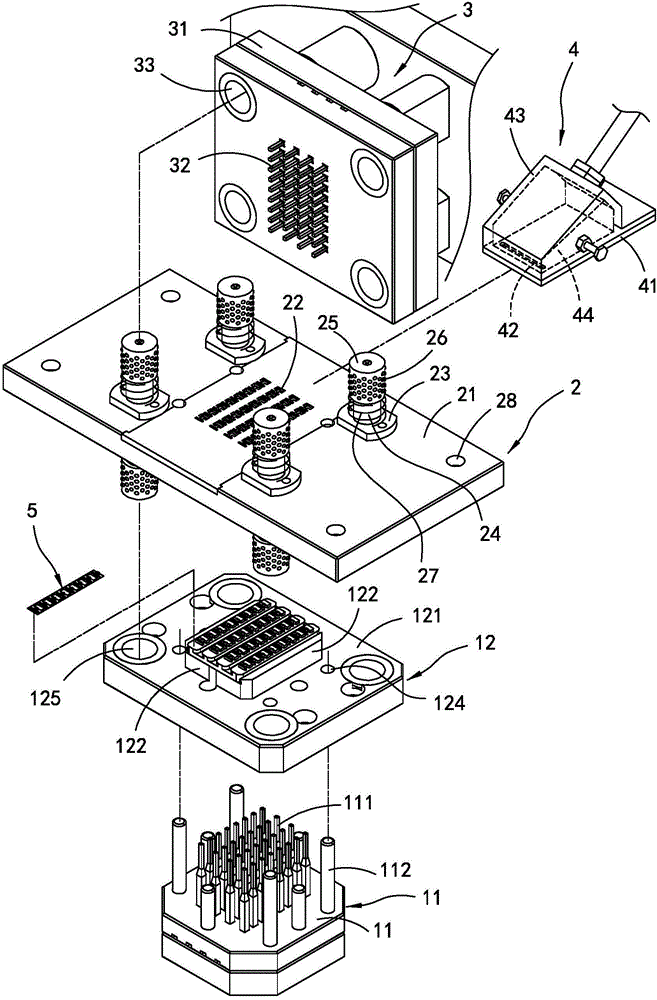

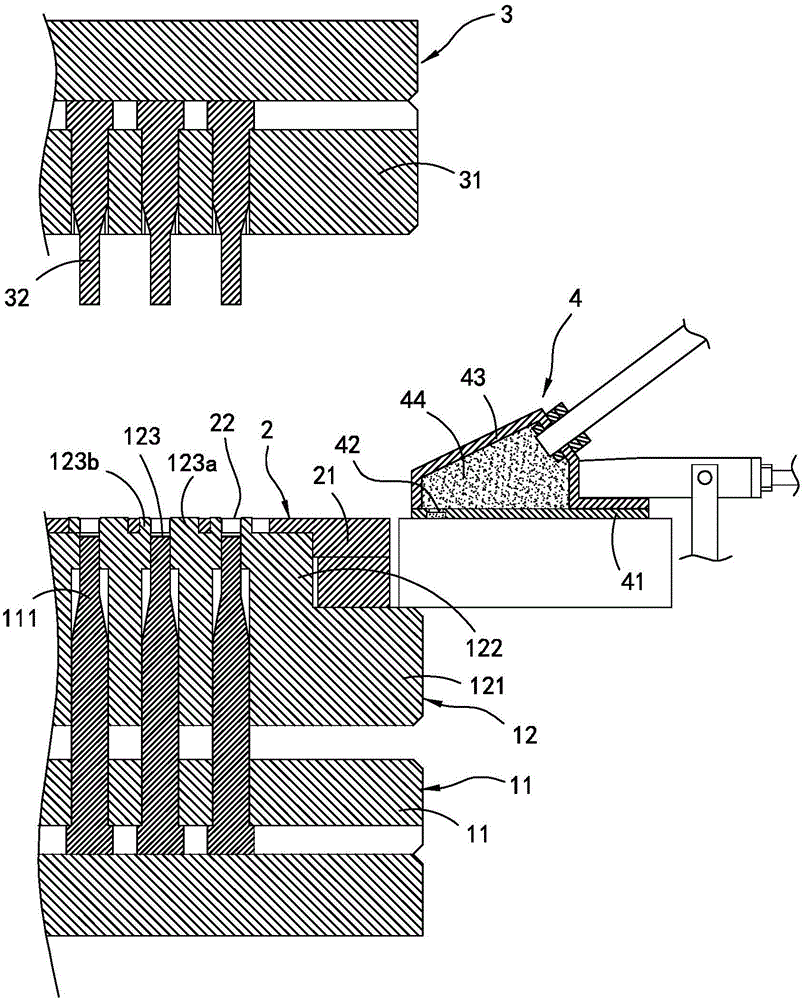

[0082] The technical content and detailed description of the present invention are now described as follows in conjunction with the accompanying drawings:

[0083] see figure 1 , a schematic flow chart of the secondary powder feeding structure for making inductors in the present invention. As shown in the figure: the secondary powder feeding production method of the inductor of the present invention is mainly used in a machine (also known as a cold press, in this paper) with a lower punching module, a stripping module, an upper punching module and a powder feeding bottom plate In the invention, the machine (referred to as the machine for short) performs secondary powder feeding to make the inductor. First, as in step 100, the machine drives the mold cover of the stripping module to move to the boss of the middle mold to close the mold, so that the two sides of the boss The protrusion is framed by the through hole of the mold cover.

[0084] Step 102, the machine drives the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com