Preparation method of hierarchical porous air electrode

An air electrode, hierarchical porous technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of high price, short cycle life, side reactions, etc., and achieve the effect of simple method, high cost efficiency and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

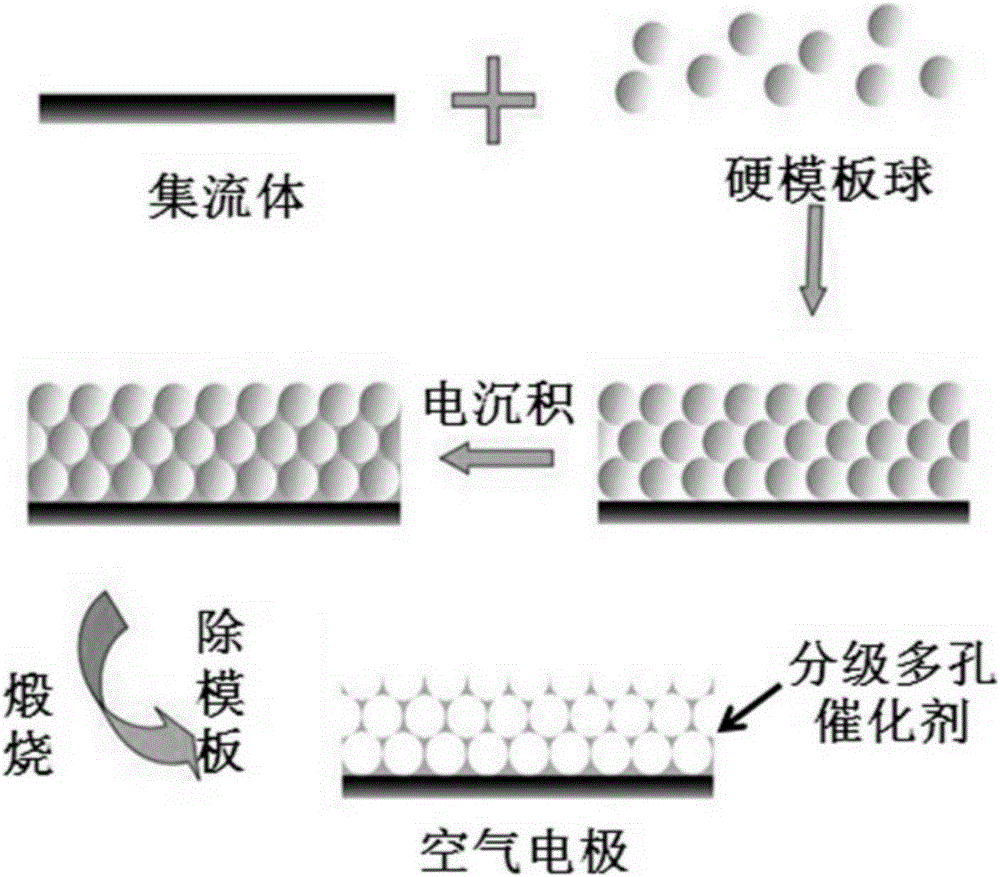

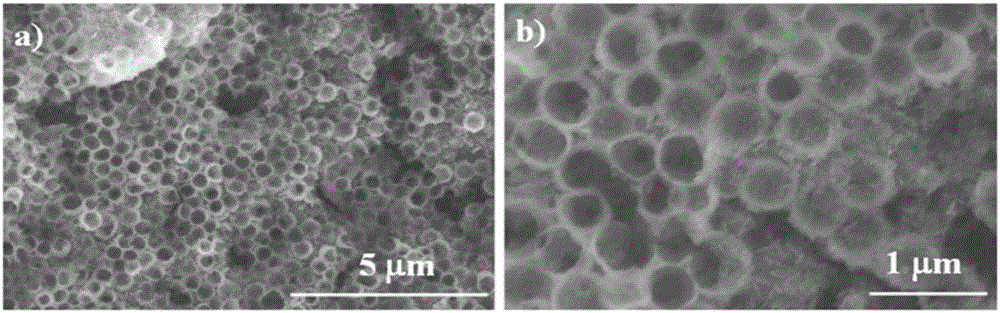

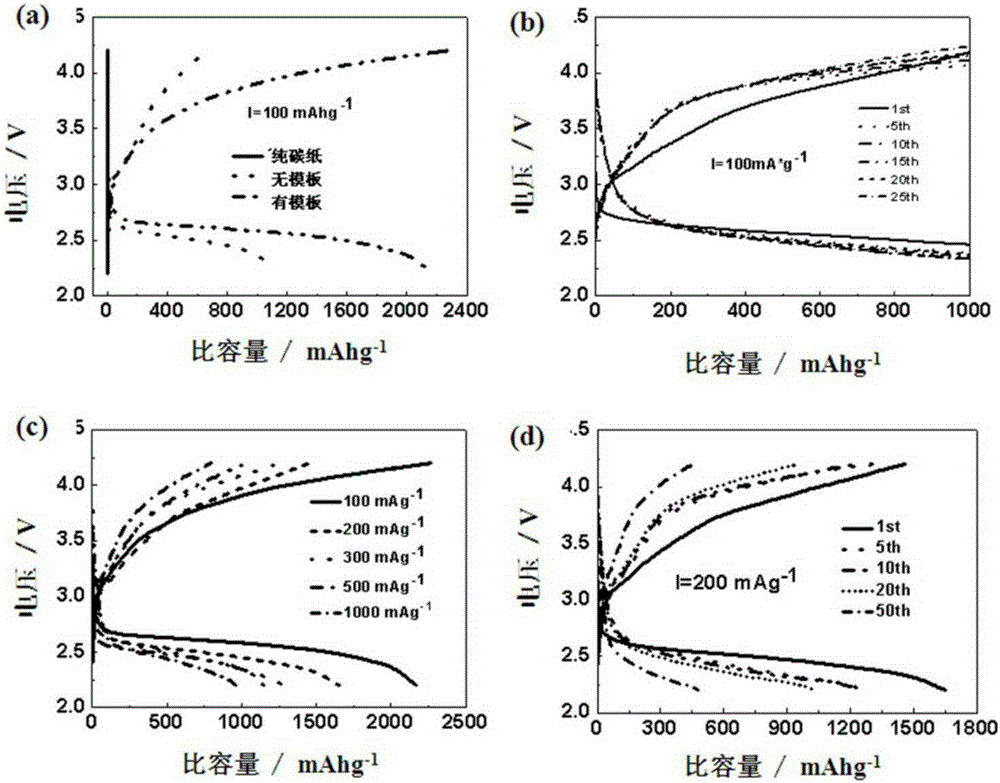

[0018] The preparation method of the hierarchical porous air electrode of the present invention comprises the following steps: (a) self-assembling a hard template on any surface of the current collector; (b) depositing and growing a metal oxide catalyst precursor on the hard template; ( c) Calcining the device obtained in step (b) to remove the hard template. The method is simple, efficient and low-cost, and the formed air electrode structure also has the following advantages: it can provide more catalytic active sites, and the open pore system provides freedom for reactant molecules to reach and leave the active sites of the catalyst. Restricted channels, discharge products are mainly deposited on the surface of the catalyst with a porous structure, etc., thereby improving the performance of the air electrode.

[0019] In the step (a), the surface of the current collector is treated (acid washing can be used, such as nitric acid solution with a mass concentration of 68%, for ...

Embodiment 1

[0024] This embodiment provides a method for preparing a hierarchical porous air electrode, such as figure 1 As shown, it includes the following steps:

[0025] (a) Select carbon paper as the current collector, ultrasonically clean it successively in acetone, isopropanol, ethanol and water, dry it in an oven for later use; place the carbon paper in a nitric acid solution with a mass concentration of 68% for 30 minutes, Its surface is negatively charged. After taking it out, clean it with deionized water and ethanol, and dry it in an oven; 2 In the ethanol dispersion of spherical hard template (the concentration of spherical hard template is 25mg / ml) for 2-5 minutes, make SiO 2 The balls are self-assembled on the surface of the current collector, then dried and dried, and repeated 3 to 5 times to ensure the formation of multiple hard template layers on the surface of the current collector to obtain a fluid / hard template substrate.

[0026] (b) Immerse the fluid / hard template ...

Embodiment 2

[0030] This example provides a method for preparing a hierarchical porous air electrode. The general steps are the same as those in Example 1, except that the hard template used is polystyrene balls; in the end, it does not need to be soaked in NaOH, but directly calcined That's it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com