Method for preparing drug-loaded injection type calcium sulfate bone cement for promoting bone growth

A technology of bone cement and calcium sulfate, which is applied in the technical field of biomedical materials, can solve problems such as prolonged curing time, achieve the effects of improving refractory and over-dense, simple preparation methods, and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

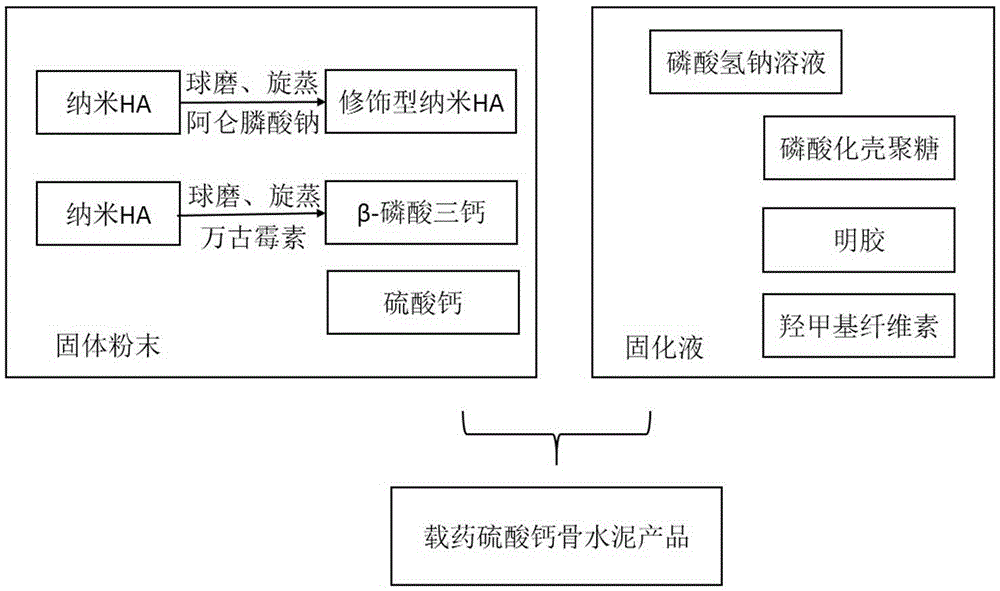

Method used

Image

Examples

Embodiment 1

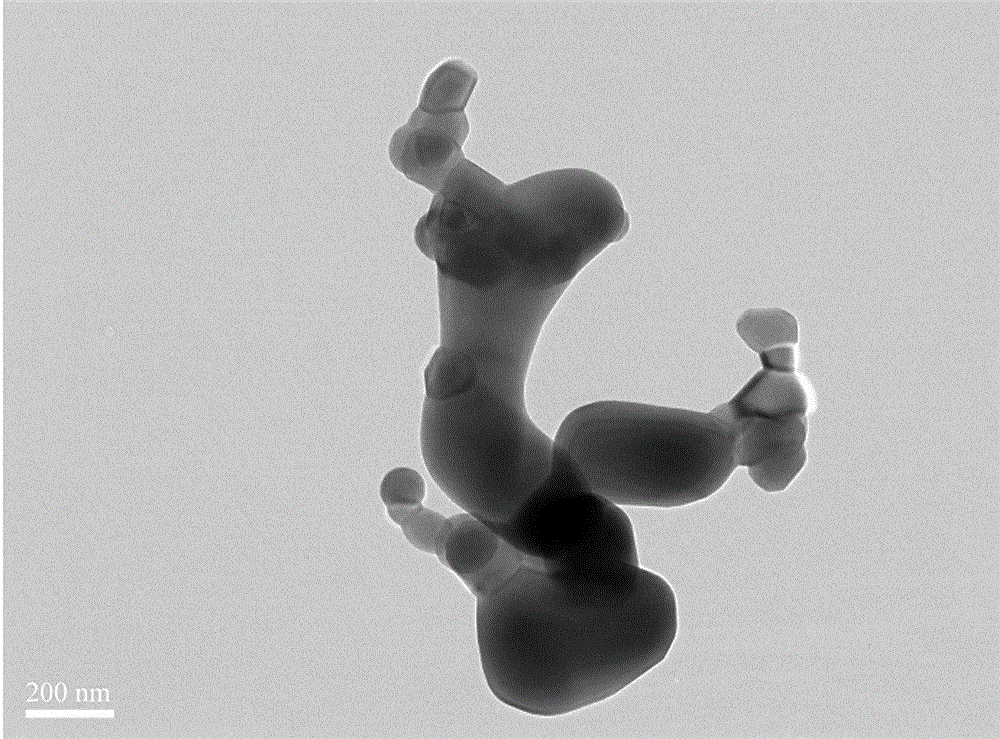

[0037] Sodium alendronate was pre-dissolved in absolute ethanol solution to form a 0.1Mol / L solution, and then self-made hydroxyapatite powder was added to the solution, mixed in a ball mill for liquid phase grinding surface modification, and rotary evaporation Powder after solvent.

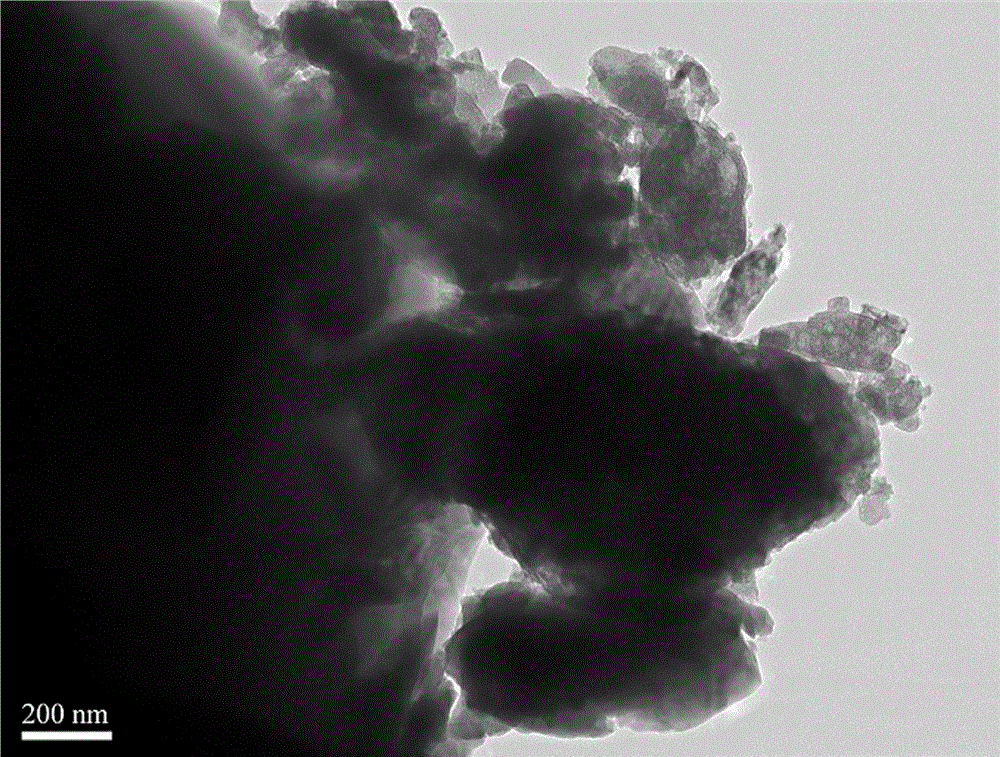

[0038] Pre-dissolve vancomycin in absolute ethanol solution to form a 0.1Mol / L solution, then add self-made β-tricalcium phosphate powder into the solution, mix in a ball mill for liquid phase grinding surface modification, and rotate the solvent to evaporate Then get powder. Use the above as a recipe alternative.

[0039] Take by weighing 0.1g phosphorylated chitosan, 0.15g gelatin, 0.1g hydroxypropyl methylcellulose, dissolve in 19.65g sodium hydrogen phosphate solution, prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan, 1.5% gelatin, 1% hydroxypropyl methylcellulose bone cement solidification solution.

[0040] Pure calcium sulfate hemihydrate is a solid phase powder, and th...

Embodiment 2

[0042] Sodium alendronate was pre-dissolved in absolute ethanol solution to form a 0.1Mol / L solution, and then self-made hydroxyapatite powder was added to the solution, mixed in a ball mill for liquid phase grinding surface modification, and rotary evaporation Powder after solvent.

[0043] Pre-dissolve vancomycin in absolute ethanol solution to form a 0.1Mol / L solution, then add self-made β-tricalcium phosphate powder into the solution, mix in a ball mill for liquid phase grinding surface modification, and rotate the solvent to evaporate Then get powder.

[0044] Calcium sulfate hemihydrate, β-tricalcium phosphate and hydroxyapatite were mixed at a ratio of 5:4:1 to prepare bone cement solid phase powder.

[0045] Take by weighing 0.1g phosphorylated chitosan, 0.15g gelatin, 0.1g hydroxypropyl methylcellulose, dissolve in 19.65g sodium hydrogen phosphate solution, prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan, 1.5% gelatin, 1% hydroxypropyl methylcellul...

Embodiment 3

[0048] Sodium alendronate was pre-dissolved in absolute ethanol solution to form a 0.1Mol / L solution, and then self-made hydroxyapatite powder was added to the solution, mixed in a ball mill for liquid phase grinding surface modification, and rotary evaporation Powder after solvent.

[0049] Pre-dissolve vancomycin in absolute ethanol solution to form a 0.1Mol / L solution, then add self-made β-tricalcium phosphate powder into the solution, mix in a ball mill for liquid phase grinding surface modification, and rotate the solvent to evaporate Then get powder.

[0050] Calcium sulfate hemihydrate, β-tricalcium phosphate and hydroxyapatite were mixed in a ratio of 5:3:2 to prepare bone cement solid phase powder.

[0051] Take by weighing 0.1g phosphorylated chitosan, 0.15g gelatin, 0.1g hydroxypropyl methylcellulose, dissolve in 19.65g sodium hydrogen phosphate solution, prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan, 1.5% gelatin, 1% hydroxypropyl methylcellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com