Hearth for hot pot

A technology for a hot pot and a stove, which is applied in the field of stoves, can solve the problems of complex structure, inconvenient installation and use, and many parts, and achieves the effects of simple structure, convenient installation and disassembly, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

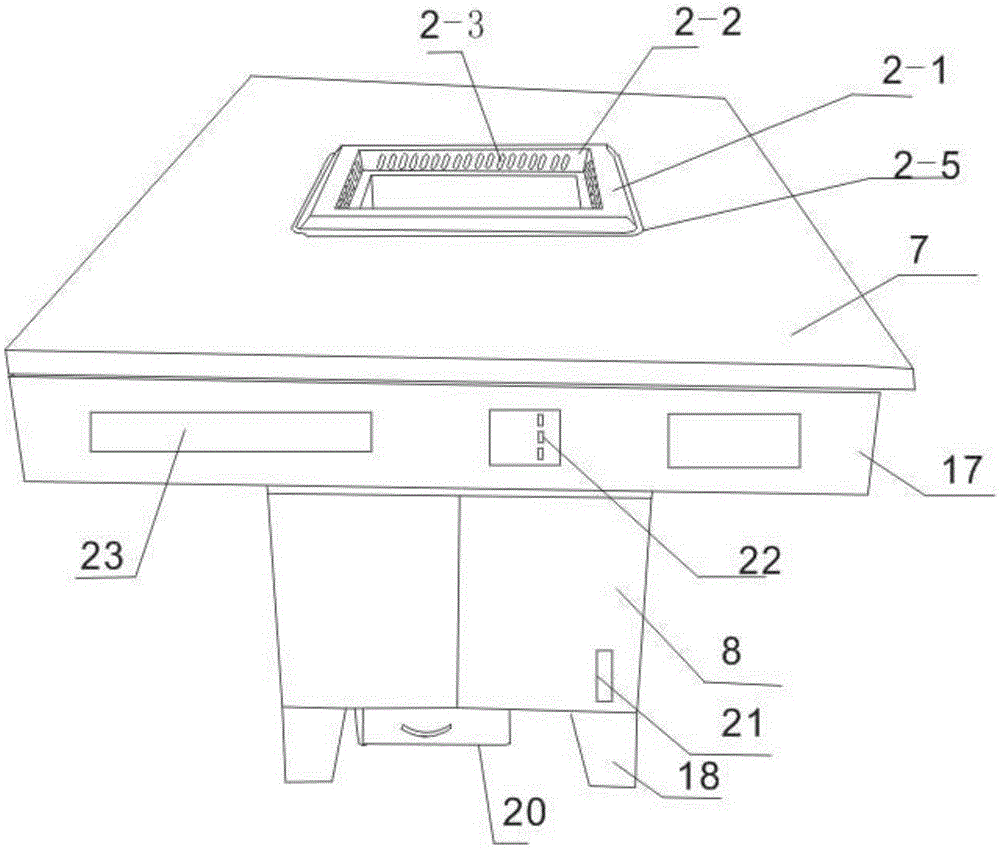

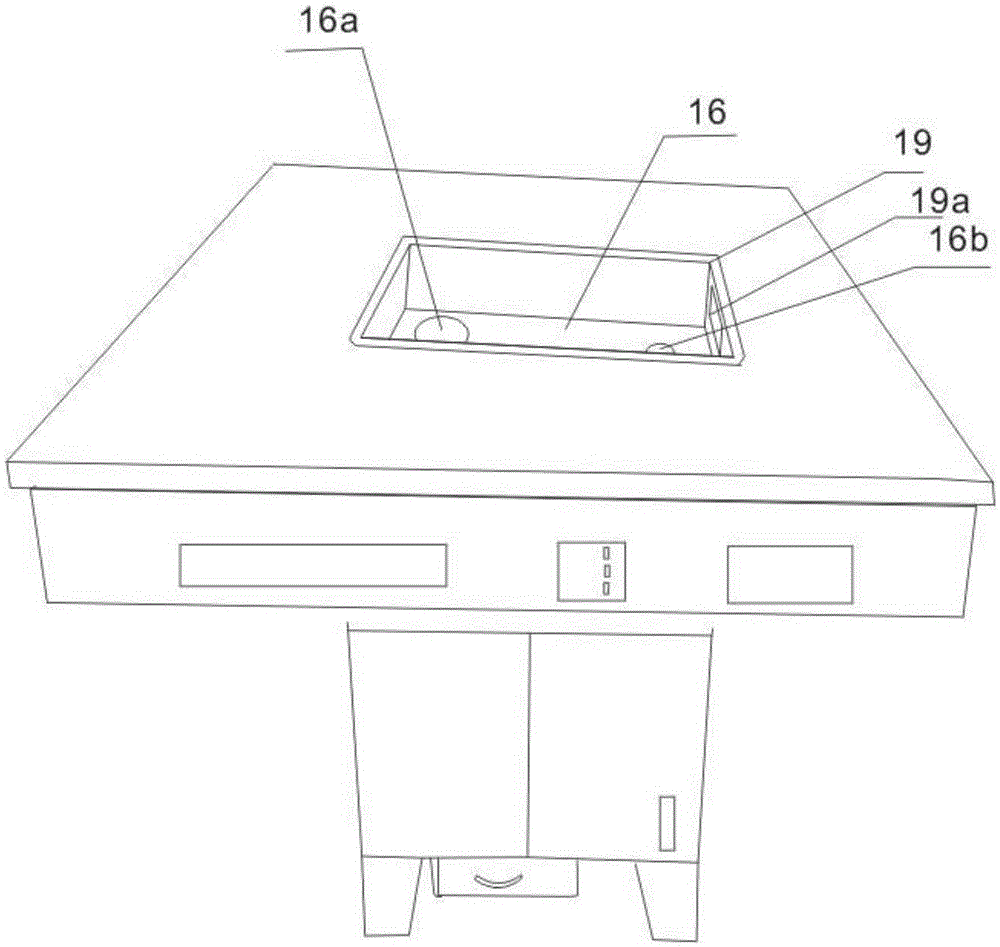

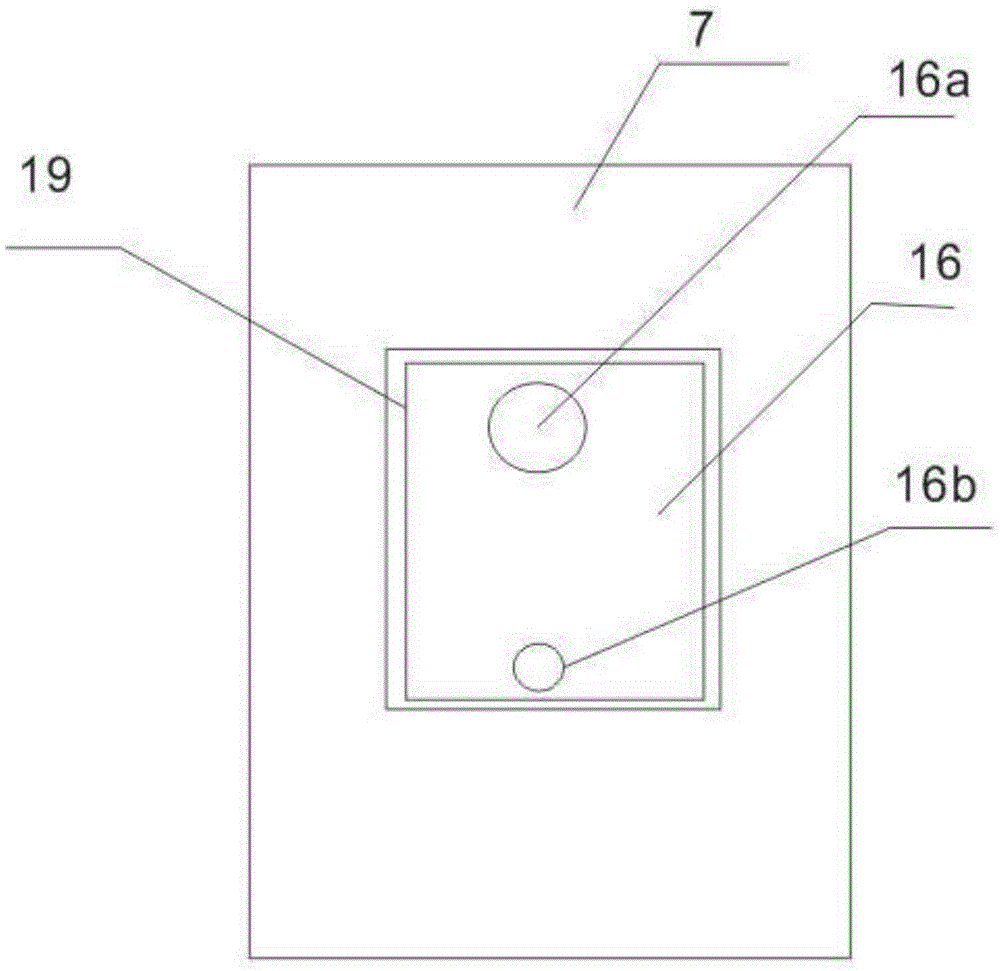

[0047] Example 1, such as Figure 1-14Shown: chafing dish table of the present invention is made up of components such as water tank 8, upper case 9, metal frame 17, table top 7, bottom bucket 19, kitchen range box, chafing dish device.

[0048] Water tank 8 comprises square water tank body, and four jiaos of the base plate of water tank 8 are provided with outer leg 18, and the outside of the lower end of the front side plate of water tank 8 is provided with water gauge 21, is convenient to observe the water level situation in water tank 8. Also be provided with water inlet and drain on the water tank 8, do not specifically show among the figure.

[0049] The left side of water tank 8 bottom plate is provided with the exhaust hole that axis extends up and down, and exhaust tube 8b is arranged on this exhaust hole, and exhaust tube 8b is near the front end of water tank 8, and exhaust tube 8b is positioned at water tank 8, and exhaust tube The height of 8b is lower than the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com