Finger mechanism of wiring robot

A robot finger and wiring technology, applied in the field of robots, can solve the problems of slow wiring operation, cumbersome wiring work, complex electrical system, etc., and achieve the effect of large wiring and wiring workload, improving wiring efficiency, and accurate wiring operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

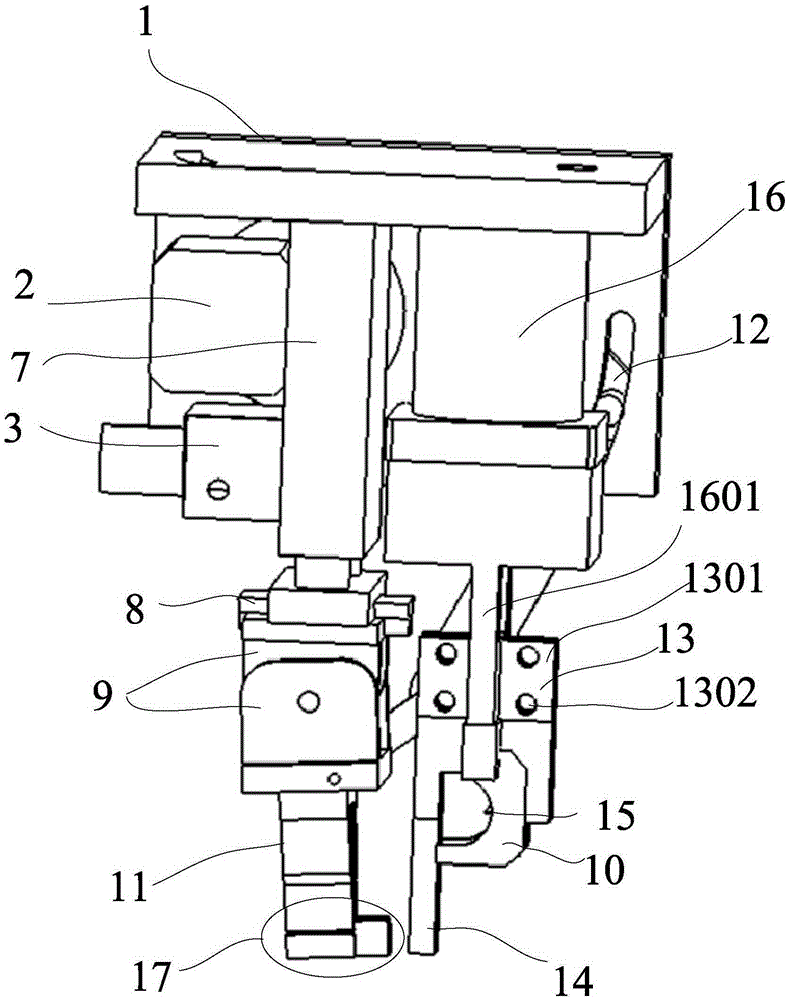

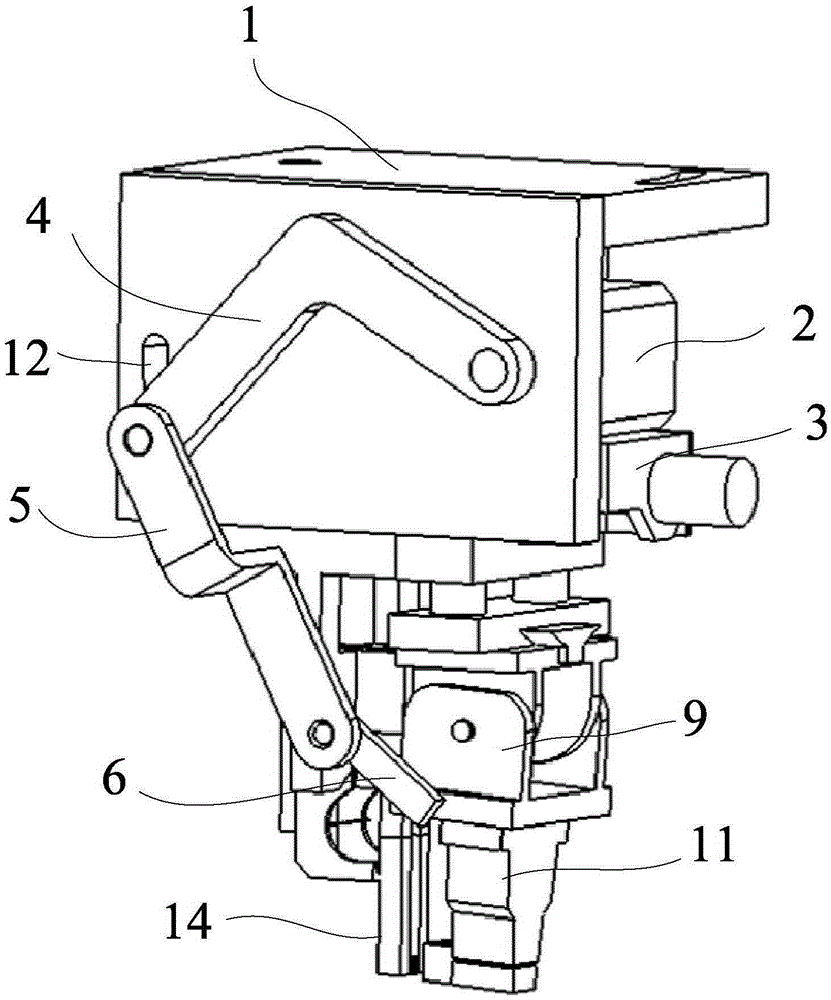

[0022] A wiring robot finger mechanism provided in this embodiment, such as figure 1 and figure 2 shown, including:

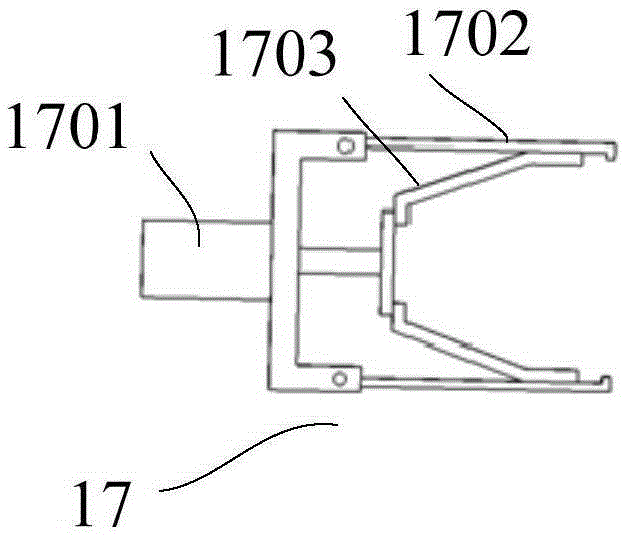

[0023] Mounting plate 1, stepping motor 2, wire feeder 3, swing connecting rod 4, angle connecting rod 5, lifting connecting rod 6, telescopic cylinder 7, slider 8, movable joint 9, wire passing device 10, wire stripping mechanism 11 , slideway 12, compression spring opening and closing bin 13, clamping finger 14, thread cutter 15, rotary drive cylinder 16, wire stripping nozzle 17;

[0024] The mounting plate 1 is used to connect the arm mechanism above the finger mechanism of the wiring robot. The arm mechanism is not within the scope of the present invention, and its structure is not given. It should be noted that the movement of the arm mechanism can drive the installation plate 1 to move or rotate, thereby driving the entire finger mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com