Two-way multi-hole drilling machine

A technology of multi-hole drilling and hole drilling machine, which is applied in metal processing and other directions, can solve the problems that the position of the drilling hole is difficult to meet the design requirements and the work efficiency is low, and achieves the effect of wide application range, high work efficiency and reduction of processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

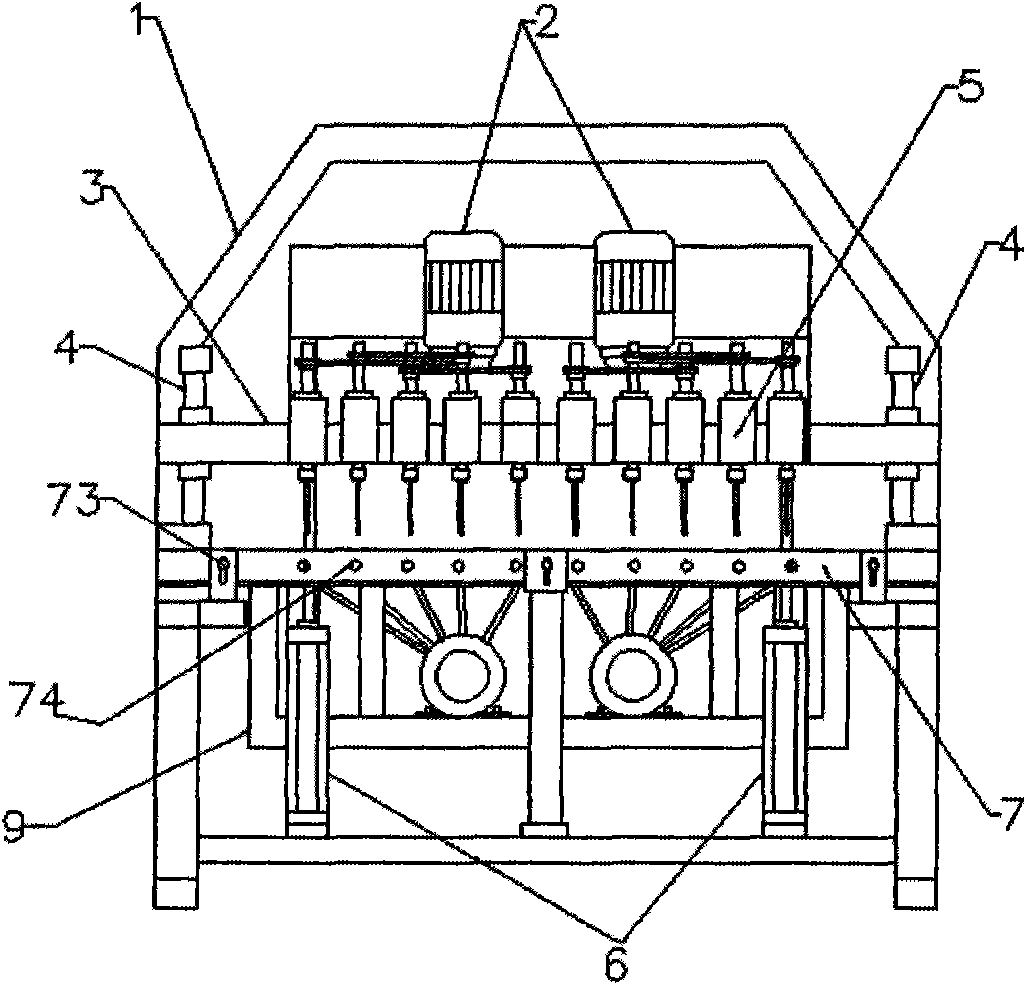

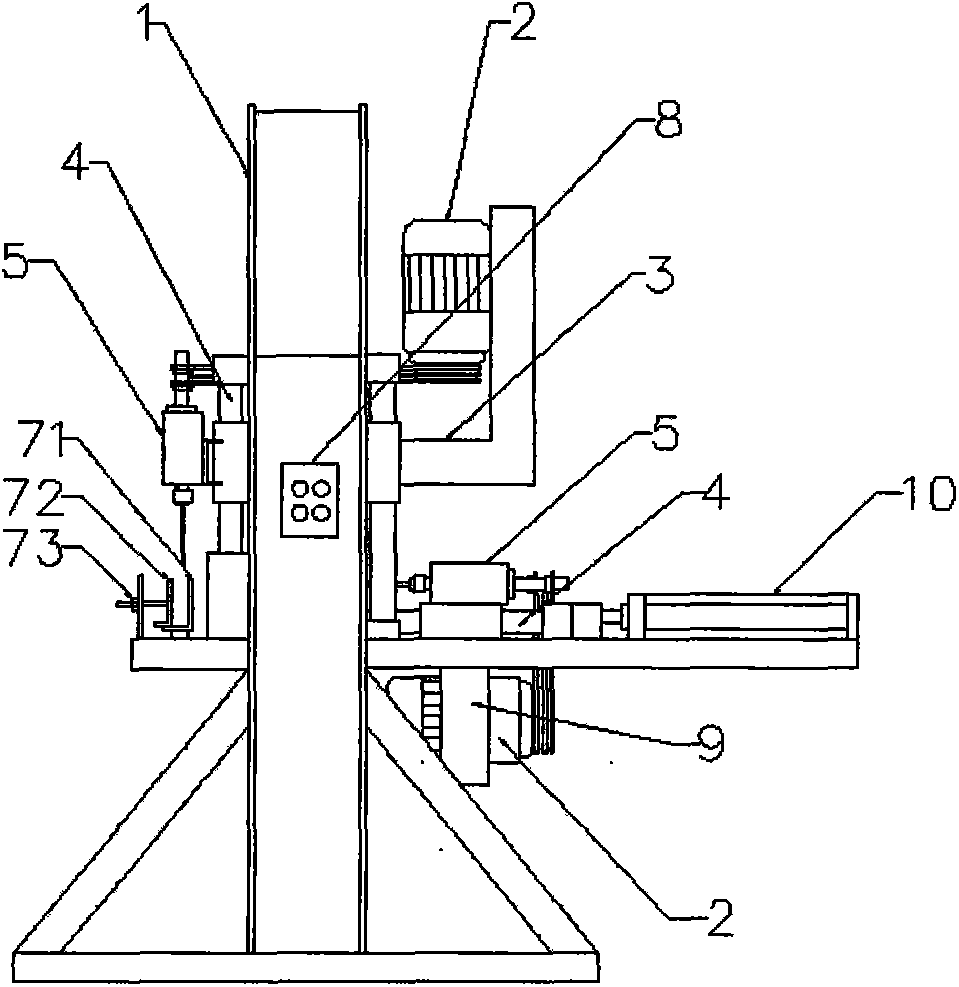

[0017] A two-way multi-hole drilling machine, including a support frame 1, a motor 2, a horizontal drilling platform 3, a longitudinal drilling platform 9, a guide shaft 4, a combined drill 5, a hydraulic lifting device, a clamp 7 and a control box 8, its The features are: the support frame 1 is provided with a horizontal drilling platform 3, a longitudinal drilling platform 9, a guide shaft 4, a hydraulic lifting device, a fixture 7 and a control box 8, and the horizontal drilling platform 3 and the longitudinal drilling platform 9 are provided with Motor 2, combination drill 5, horizontal drilling platform 3 and longitudinal drilling platform 9 are connected with hydraulic lifting device, and move along with the motion of hydraulic lifting device. The four corners of the horizontal drilling platform 3 and the longitudinal drilling platform 9 are provided with sleeves, which are respectively sleeved on the guide shaft 4 of the support frame. The horizontal drilling platform 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com