Laterally locking type double-layer vibration damping fastener

A vibration-damping fastener and double-layer technology, applied in the directions of roads, tracks, buildings, etc., can solve the problems of difficulty in repairing and replacing the vibration-damping cushion, easy peeling of the vulcanized rubber layer, and high maintenance and repair costs, so as to facilitate maintenance, repair and replacement. The middle elastic cushion is simple and the vibration reduction effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below according to the drawings and embodiments.

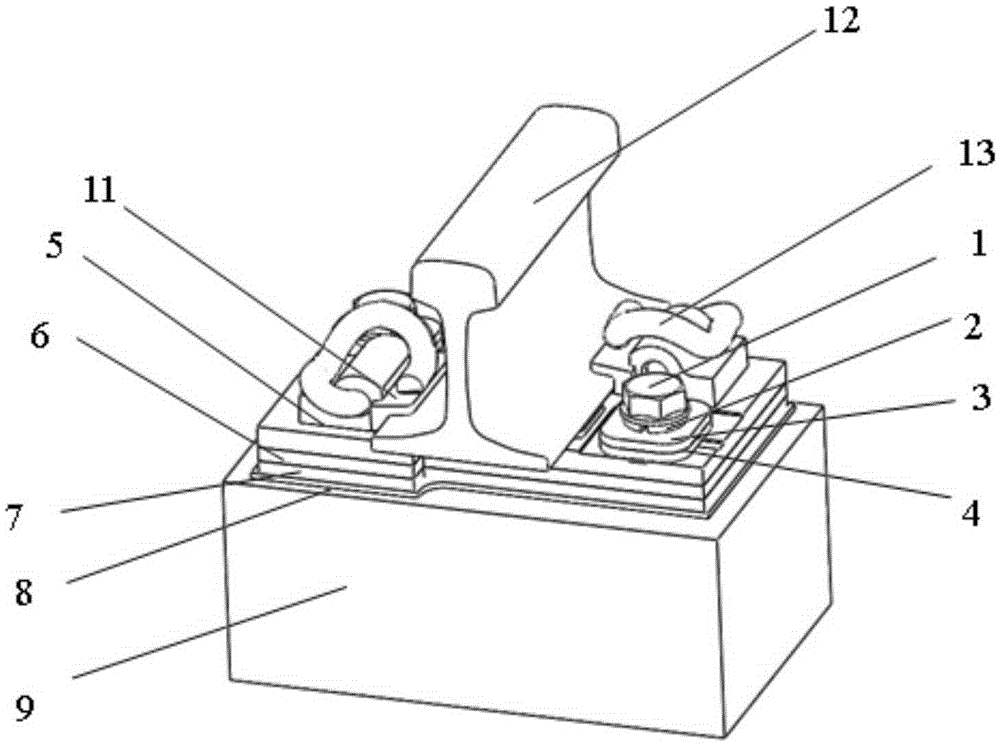

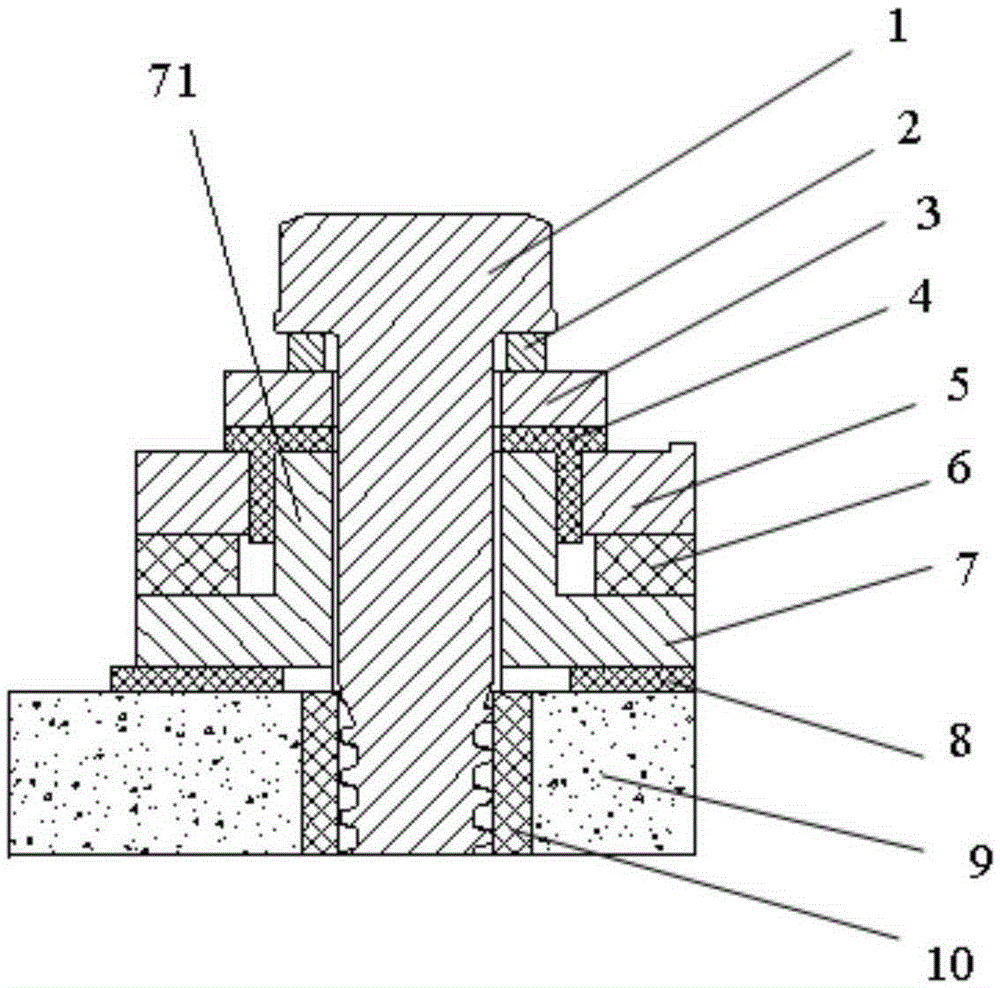

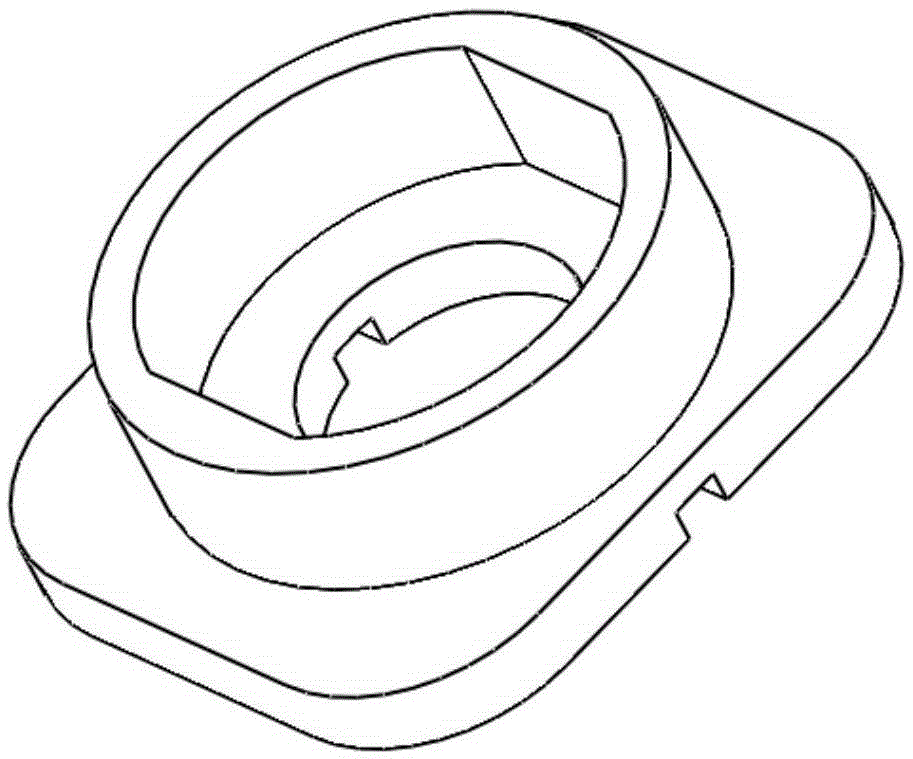

[0020] refer to Figure 1-Figure 6 , the present invention, the side-lock type double-layer damping fastener, including anchor bolt 1, heavy spring washer 2, flat spacer 3, nylon insulation cover 4, upper iron backing plate 5, middle elastic backing 6, lower iron backing plate 7. Insulation cushion plate 8, base 9, nylon sleeve 10, insulation gauge block 11, steel rail 12, elastic bar 13.

[0021] The structure of the fastener is as follows: a nylon sleeve 10 is pre-embedded in the base 9, an insulating cushion plate 8 is directly laid on the base 9, and the lower iron plate 7 and the middle elastic pad are successively laid on the insulating cushion plate 8. Layer 6 and the upper iron backing plate 5, there are two protruding columns 71 on the lower iron backing plate 7, and there is a through hole in the middle of the column 71, the through hole and the bolt h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap