Applicable to the method of changing the steel derrick to the well tower in the underground mining hoisting system

A hoisting system and underground mining technology, applied in shaft equipment, mining equipment, earth-moving drilling, etc., can solve the problems of easy slippage of the first rope, easy freezing of the crown wheel and the first rope, hidden safety hazards, etc. The effect of strong safety and reliability and construction quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

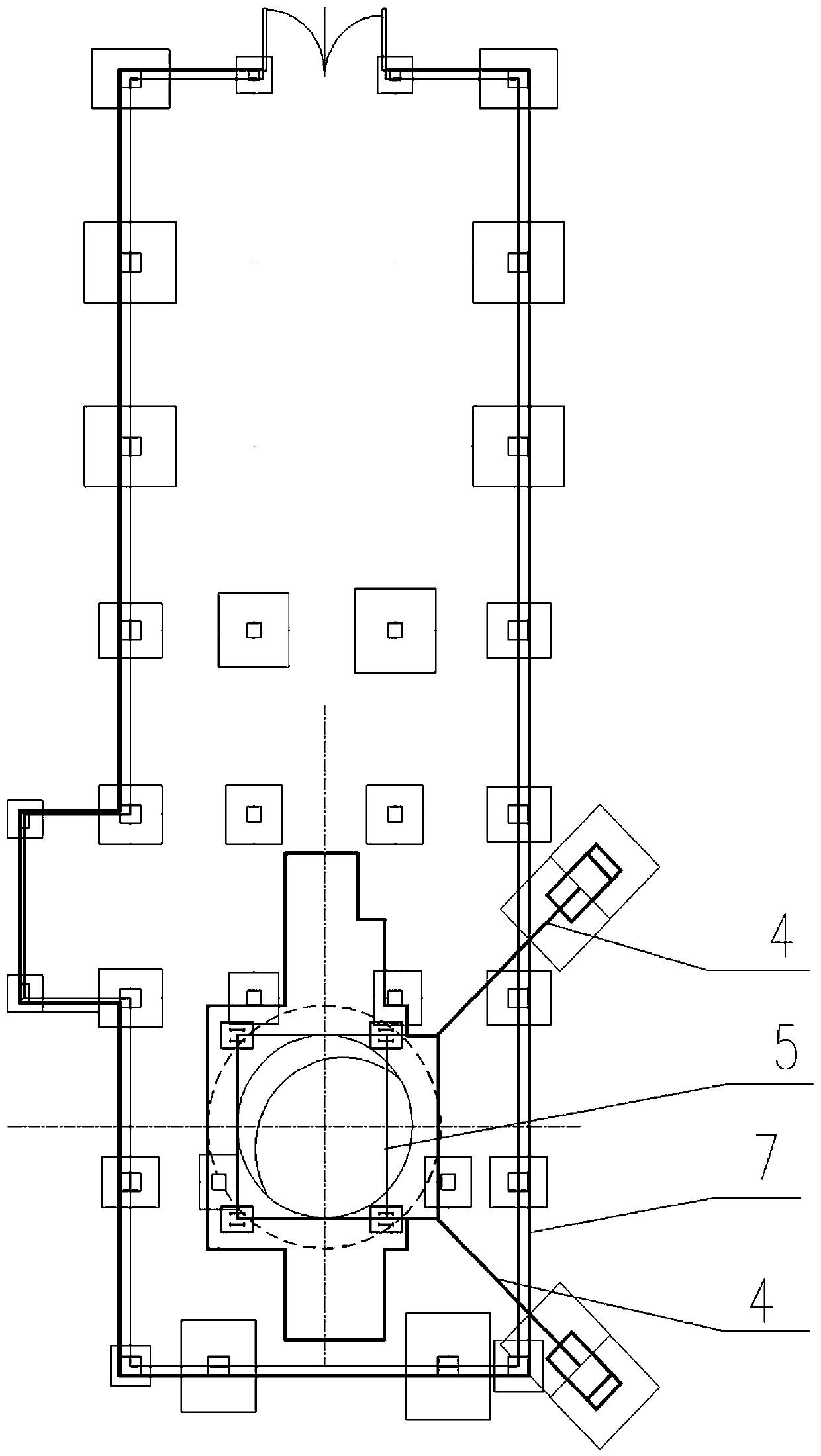

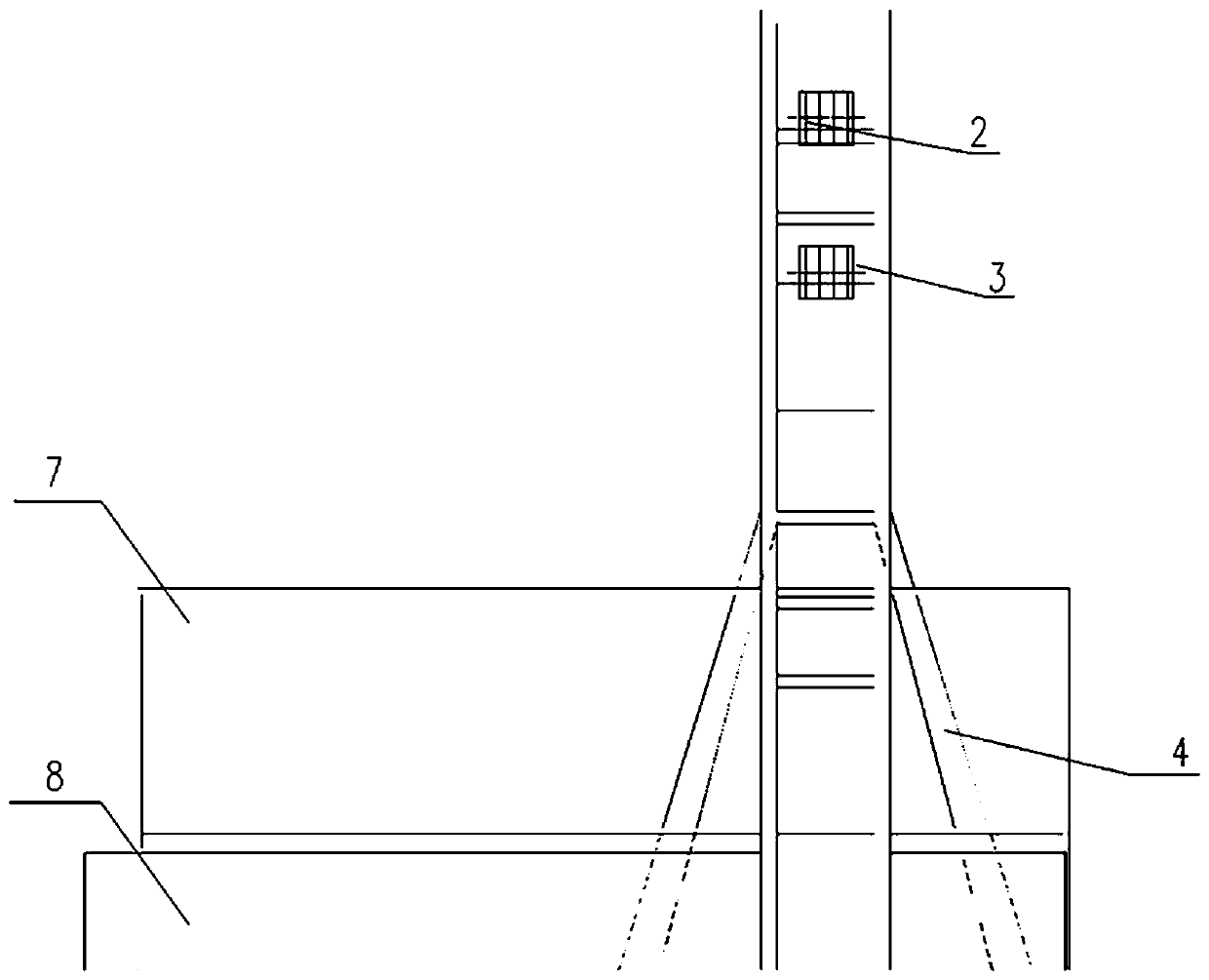

[0032] figure 1 and figure 2 It is a common and representative oblique bracing steel derrick structure in the existing steel derrick. It generally includes the original steel derrick lifting device 1, the original steel derrick upper sky wheel 2, the original steel derrick lower sky wheel 3, the original steel derrick diagonal brace 4, the original steel derrick vertical frame 5, the original steel wire rope 6, the original wellhead room 7, etc. Generally, the derrick is divided into 4 platform layers: the upper sky wheel platform ①, the lower sky wheel platform ②, the top platform of the vertical frame ④, and the wellhead platform (ground) ⑥. For example, the auxiliary shaft hoisting system of a gold-copper mine in Hubei is currently using this kind of diagonally braced steel derrick. The plane projection size of the main part of the derrick is 6.5m×9m, and the height is 35m. The center elevation of the upper sky wheel is 57.1m, and the center elevation of the lower sky whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com