A high-speed, low-inclusion electroslag remelting device and its remelting method

A low-inclusion, electroslag remelting technology, applied to low-inclusion electroslag remelting devices, high-speed fields, can solve the problems of accelerated consumable electrode melting, low remelting efficiency, and inclusions, etc. The effect of energy consumption, production efficiency improvement, and purity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

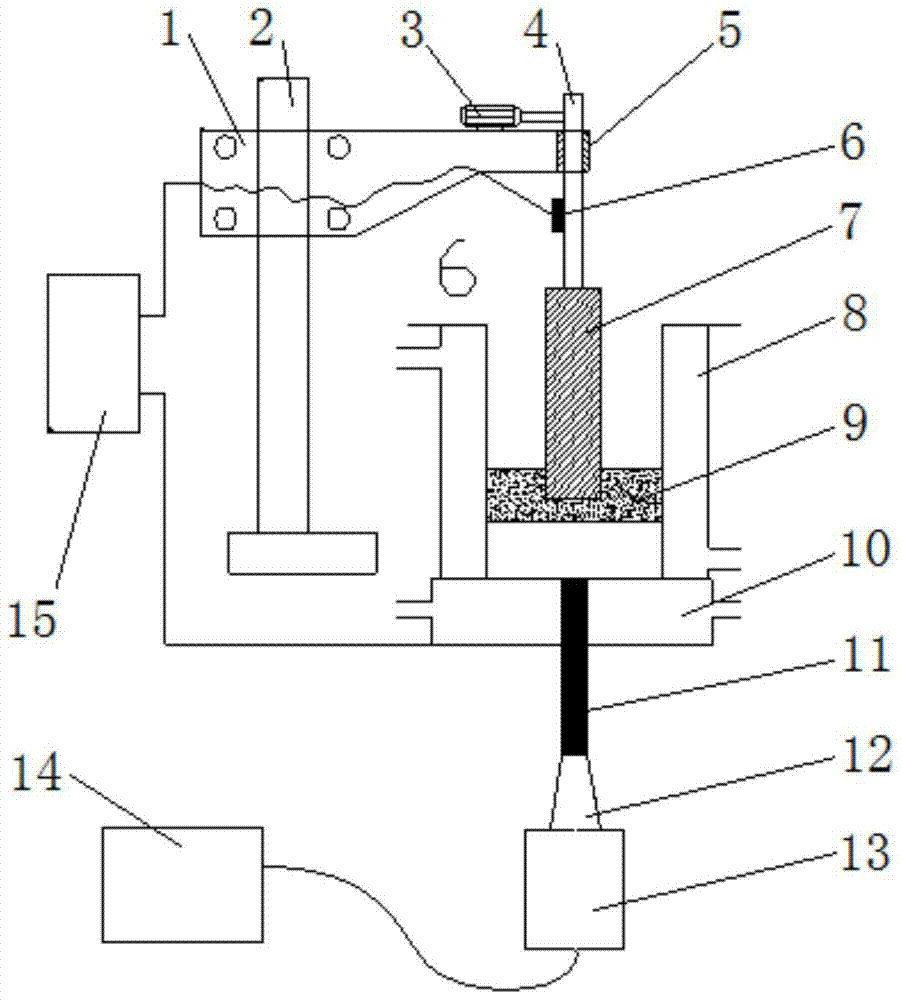

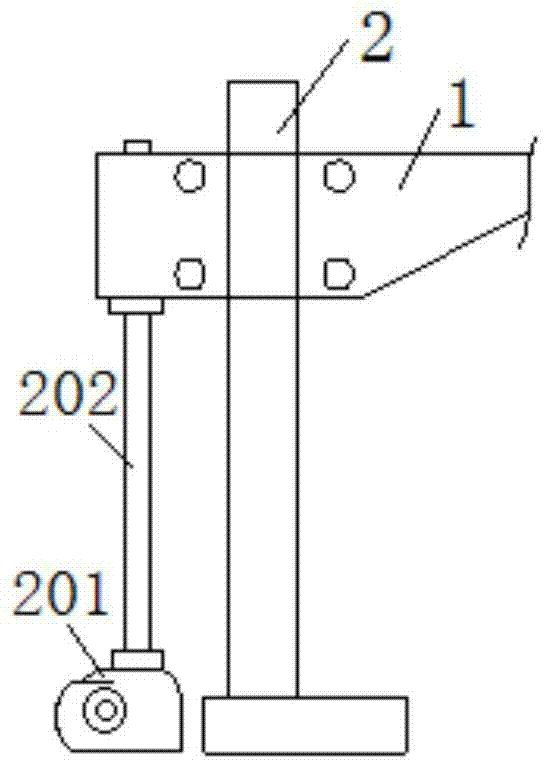

[0039] to combine figure 1 , a high-speed, low-inclusion electroslag remelting device in this embodiment includes a transformer 15, a consumable electrode 7, a crystallizer 8, an electrode drive mechanism, and an ultrasonic generator installed at the bottom of the crystallizer 8. Among them, the electrode driving mechanism is mainly composed of a fixing device, a speed-regulating motor 3 and a dummy electrode 4. The dummy electrode 4 is made of cylindrical metal material. The axes of the consumable electrodes 7 coincide; the other end of the dummy electrode 4 is connected with the bearing 5 on the fixing device, so that the dummy electrode 4 can rotate in the bearing 5 . The upper section of the dummy electrode 4 protrudes from the upper side of the bearing 5, and is connected to the speed-regulating motor 3 installed on the fixing device through a reduction gear, and the dummy electrode 4 is controlled to rotate by the speed-regulating motor 3 .

[0040]One end of the transf...

Embodiment 2

[0052] A high-speed, low-inclusion electroslag remelting method in this embodiment has the same basic steps as in Embodiment 1, the difference is that in this embodiment, the consumable electrode maintains a rotating speed of 20r / min, and the ultrasonic power Adjusted to 10W / cm 2 , Add Al-Mn-Si alloy to the slag pool for deoxidation, the addition amount is 5Kg / t steel.

Embodiment 3

[0054] A high-speed, low-inclusion electroslag remelting method in this embodiment has the same basic steps as in Embodiment 1, the difference is that in this embodiment, the consumable electrode maintains a rotating speed of 30r / min, and the ultrasonic power Adjusted to 5W / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com