A Welded and Supported Tire Frame with Variable Angle Plate Units

A tire-supporting, angle-changing technology, which is applied to welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that affect the construction period and economic benefits, cannot be reused, increase costs, etc., and reduce operation. Difficulty and labor intensity, shortening the construction period, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

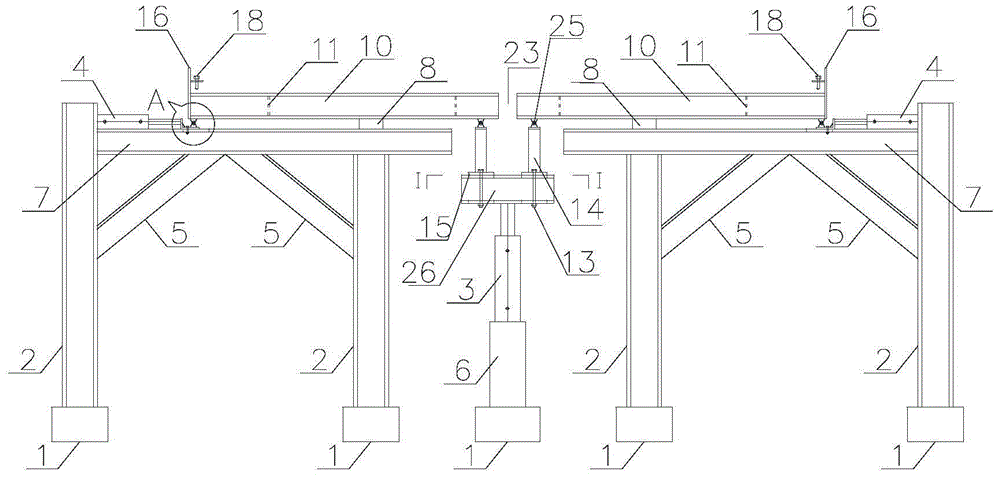

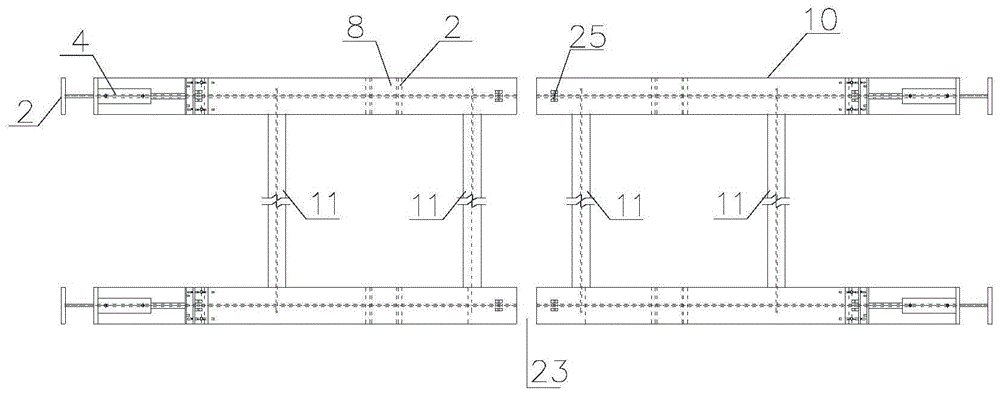

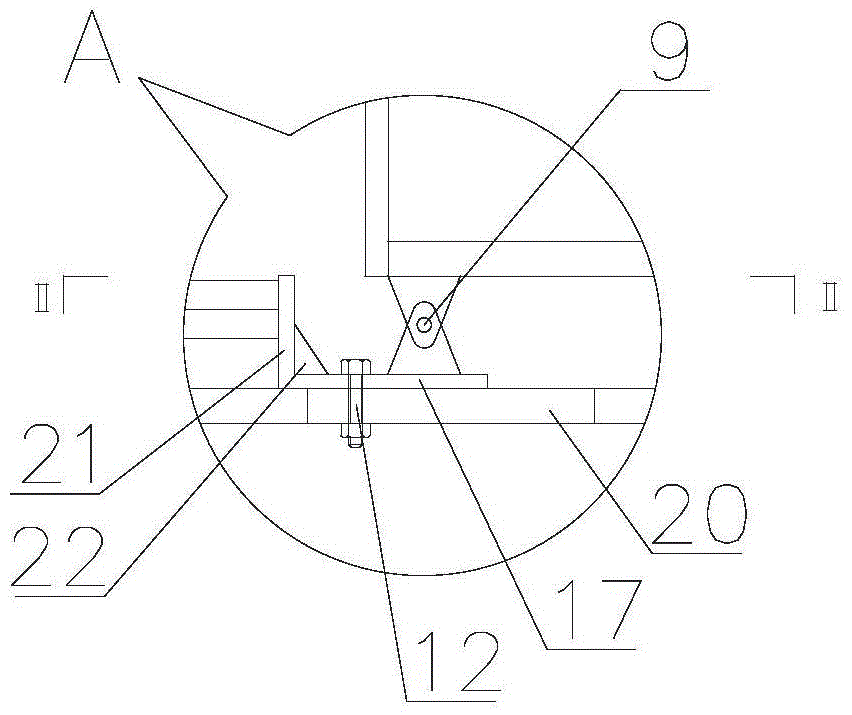

[0014] Such as Figure 1 to Figure 7 As shown, a variable-angle plate unit welded support tire frame of the present invention includes symmetrically arranged left and right concrete base groups, and each side of the concrete base group includes two rows of concrete bases 1 arranged in parallel and opposite to each other. Concrete base 1 can be provided with at least two, on each concrete base vertically fixed with tire frame upright 2, on the same side and on the same row of tire frame uprights 2 welded with tire frame crossbeam 7, preferably in Diagonal braces 5 for supporting the tire frame beams 7 are welded between the tire frame uprights 2 and the tire frame beams 7 on the same side and in the same row, and a top connection is provided between the left and right concrete base groups. There are two concrete bases 1 with two hydraulic cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com