High thermal conductive silicone grease and preparation method thereof

A technology of thermal conductive silicone grease and high thermal conductivity, applied in the field of polymer interface materials, can solve the problems of poor relative thermal conductivity and low thermal conductivity of heat-dissipating silicone grease, achieve strong heat transfer ability, high thermal conductivity, and overcome low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

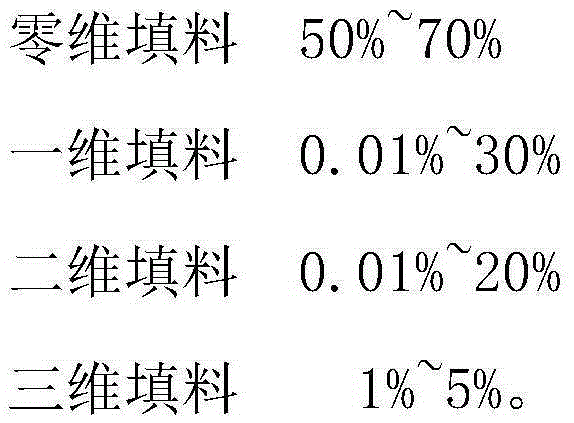

Method used

Image

Examples

Example Embodiment

[0035] Example 1

[0036] A high thermal conductivity silicone grease, including the following components, in parts by mass: 28.98 parts of silicone oil, 70 parts of aluminum nitride, 0.01 parts of carbon nanotubes, 1 part of graphene foam, and 0.01 parts of graphene sheets.

[0037] Among them, the particle size of aluminum nitride is 3-5 μm, the silicone oil is methyl long-chain alkyl silicone oil, and the viscosity is 500 cps at 25°C.

[0038] Preparation

[0039] Add silicone oil and thermally conductive filler to a double planetary mixer for mixing and stirring for 20 minutes, and then grind and disperse it on a three-roll mill for 2 times after stirring, and then vacuum and stir under vacuum for 1 hour to obtain the final silicone grease. After measurement, its thermal conductivity is 0.9W / m·K.

Example Embodiment

[0040] Example 2

[0041] A high thermal conductivity silicone grease, comprising the following components, by mass: 2 parts of silicone oil, 50 parts of graphite, 13 parts of carbon fiber, 10 parts of carbon nanotubes, 5 parts of graphene foam, and 20 parts of graphene sheets.

[0042] Among them, the particle size of graphite is 3500 mesh, the silicone oil is a mixture of phenyl silicone oil, vinyl silicone oil and hydroxy silicone oil, and the viscosity at 25°C is 15000 cps.

[0043] Preparation

[0044] Add silicone oil and thermally conductive filler to a small kneader for mixing and stirring for 20 minutes. After stirring evenly, grind and disperse 3 times on a three-roll mill, then vacuum and stir for 2 hours under vacuum to obtain the final silicone grease. After measurement, its thermal conductivity is 1.1W / m·K.

Example Embodiment

[0045] Example 3

[0046] A high thermal conductivity silicone grease, including the following components, by mass: 25 parts of silicone oil, 50 parts of graphite, 20 parts of alumina, 0.5 parts of carbon fiber, 1 part of graphene foam, 2.5 parts of graphene sheets, 1 part of carbon nanotubes Parts; among them, graphite is flake graphite, the particle size of graphite is 3500 mesh, and the particle size of alumina is 0.02-20μm. Among them, the silicone oil is a mixture of amino silicone oil and dimethyl silicone oil, and the viscosity is 1000cps at 25°C.

[0047] Preparation

[0048] Add silicone oil and thermally conductive filler to a double planetary mixer for mixing and stirring for 20 minutes. After evenly stirring, grind and disperse on a three-roll mill for 3 times, then vacuum and stir for 2 hours under vacuum to obtain the final silicone grease. After measurement, its thermal conductivity is 1.8W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap