Centrifugal pendulum vibration absorber

A centrifugal pendulum, shock absorber technology, used in shock absorbers, inertia effect shock absorbers, shock absorbers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

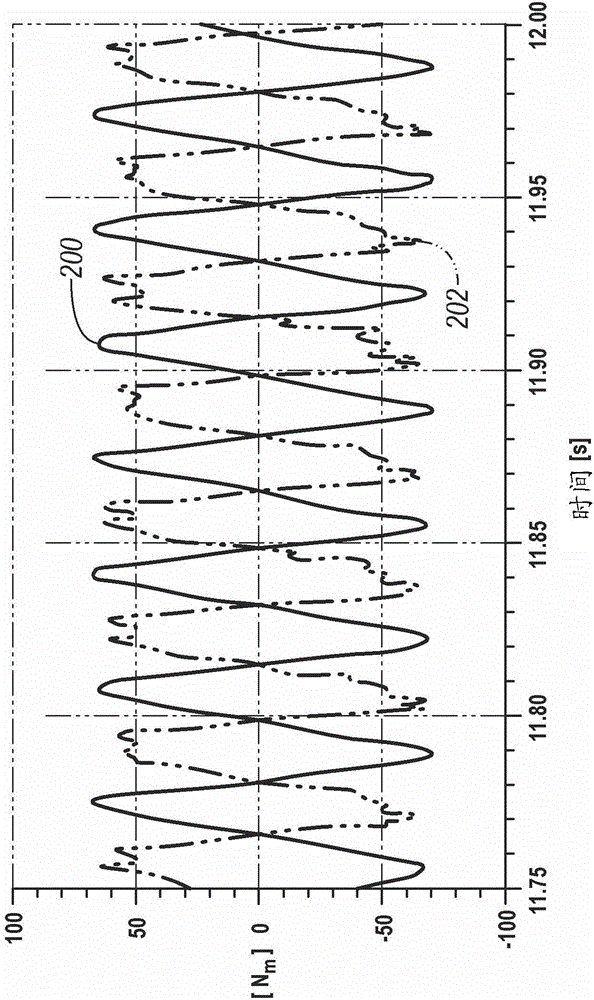

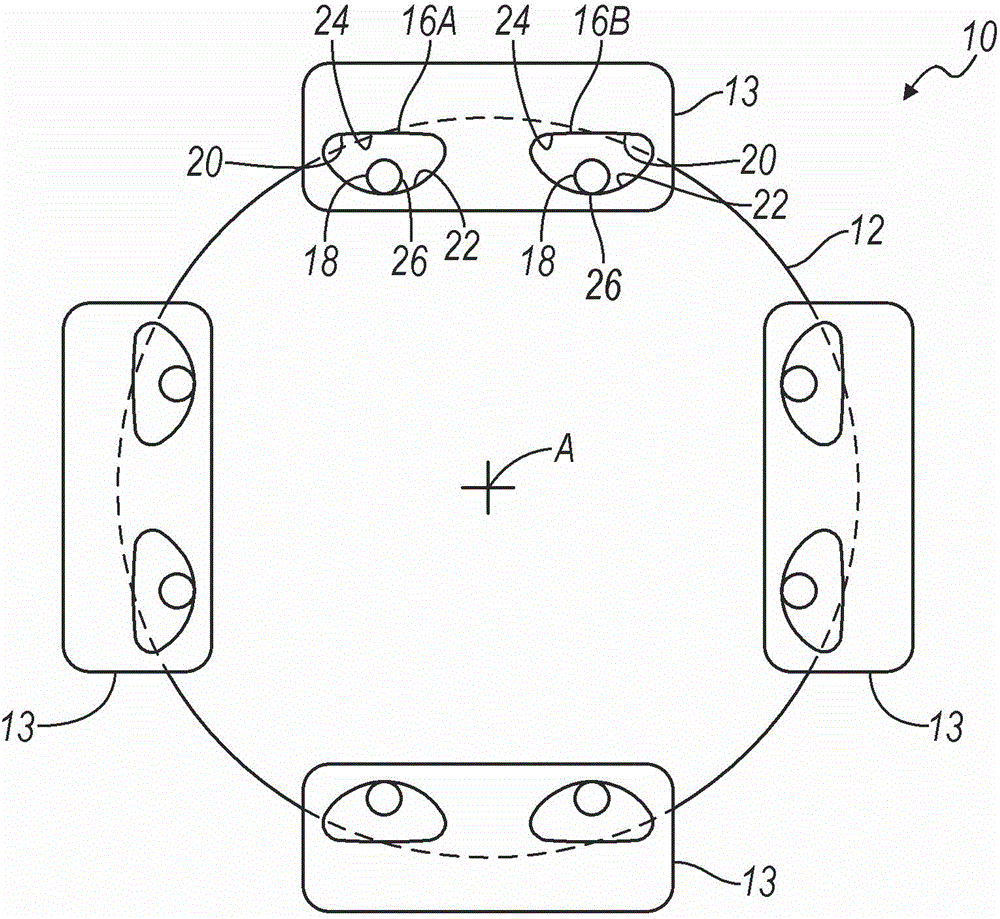

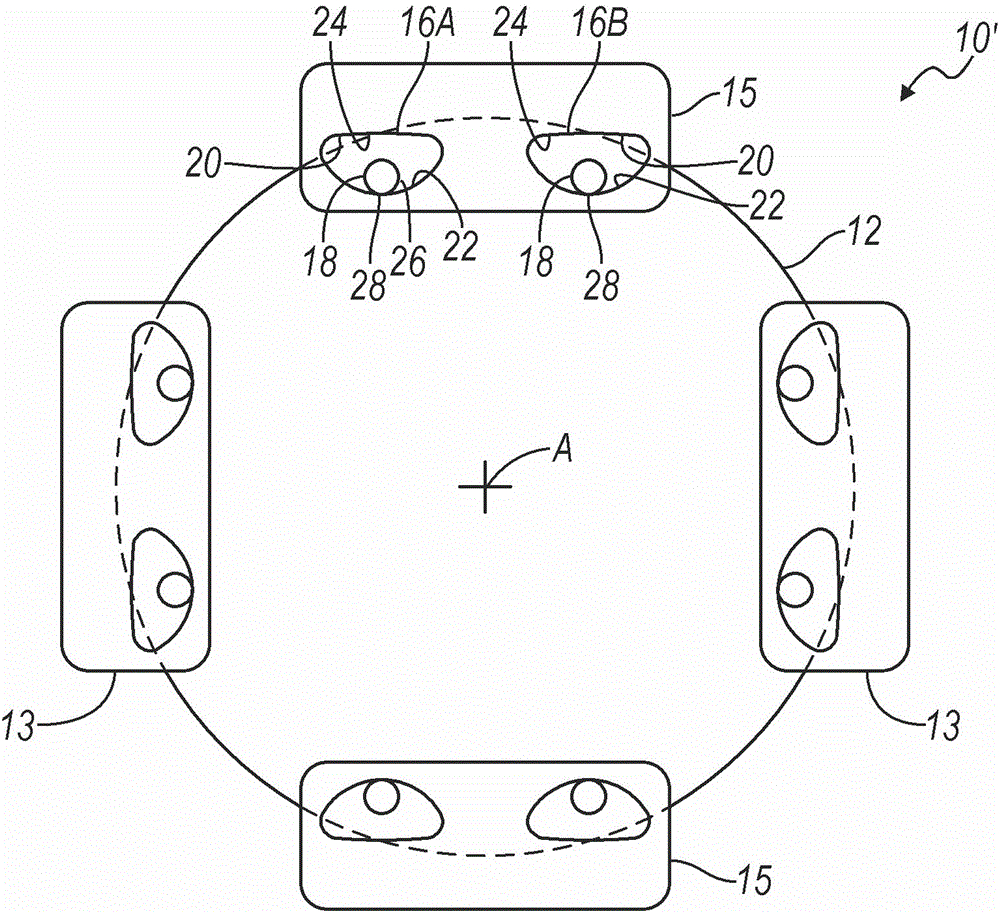

[0046] The following description is merely exemplary in nature, and is not intended to limit the disclosure, application, or uses. Referring to FIG. 1 , a centrifugal pendulum damper (CPVA) system is generally indicated by reference numeral 10 . The CPVA system 10 includes a rotating plate 12 and a set of shock absorbers 13 having a plurality of pendulums movably connected to the first plate 12 . Plate 12 is driven by a torque generator to provide drive torque to plate 12 . Accordingly, the plate 12 is rotatable about an axis “A” concentric with the plate 12 . Plate 12 is operable to transmit torque to another component in the motor vehicle, such as a transmission component. For example, plate 12 may be connected to another rotatable plate or member (not shown), which is preferably part of a torque transmitting device such as a torque converter like an automatic transmission or a clutch for a manual transmission. It should be understood, however, that the plate 12 may be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com