Non-open-fire cigarette lighting device high in radiating performance

A technology with no open flame and high heat dissipation. It is applied in the direction of combustion ignition, incandescent ignition, lighting and heating equipment, etc. It can solve the problems of reducing device heat generation, low heat utilization efficiency, and large heat generation, so as to reduce heat transfer and reduce the surface area. temperature, the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

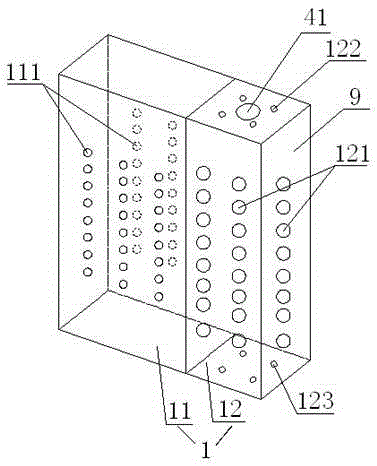

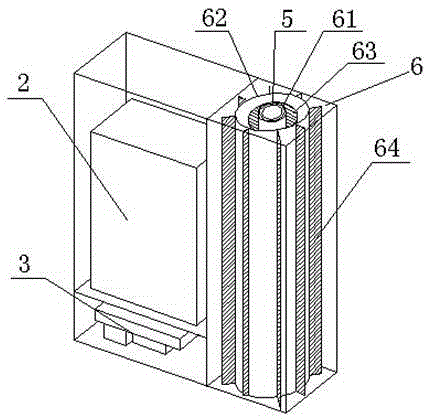

[0030] Such as figure 1 with 2 As shown, a high heat dissipation performance non-open flame cigarette lighter includes a accommodating cavity 1. The accommodating cavity includes an adjacent first accommodating room 11 and a second accommodating room 12; the first accommodating room 11 is provided with a battery 2 and In the circuit module 3 for controlling heating; an electric heating device 4 is provided in the second containing chamber 12, the electric heating device 4 is located at the lower end of the second containing chamber 12, and the electric heating device 4 is an electric heating wire layer or a heating film. The top of the second containment chamber 12 is provided with an opening 41 for inserting cigarettes into the electric heating device; the outer wall of the electric heating device 4 is provided with an insulation layer 5, and the insulation layer 5 is provided with a heat dissipation mechanism 6; A heat dissipation hole 111 is provided on the...

Example Embodiment

[0034] Example 2

[0035] This embodiment is the second embodiment of the present invention. The difference from Embodiment 1 is:

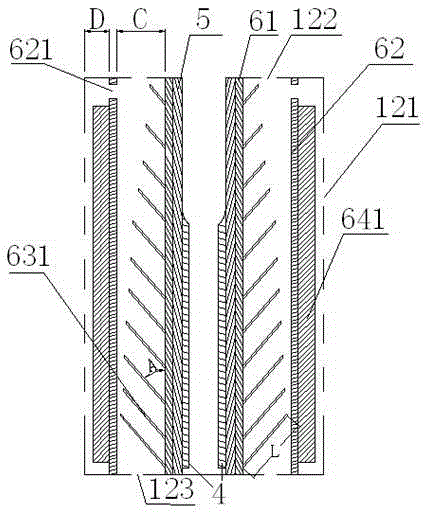

[0036] Such as image 3 with 4 As shown, the first heat dissipation fin group 63 includes a plurality of first heat dissipation fins 631. The first heat dissipation fins are distributed along the axis of the second receiving chamber 631. One end of the first heat dissipation fin 631 is connected to the first heat dissipation fin 631. The layers 61 are connected, and the other end faces the top of the second containing chamber 12. In the axial section of the second containing chamber, the first heat dissipation fin 631 and the first heat dissipation layer 61 form a first angle A, and the angle of the first angle is 30°~80°, preferably 45°. Airflow holes 6311 are provided on the first heat dissipation fins, and the axial cross-sectional length L of the first heat dissipation fins 631 gradually decreases toward the opening direction to reduce air resis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap