Lithium ion battery flexible packaging material, and lithium ion battery prepared from lithium ion battery flexible packaging material

A lithium-ion battery and flexible packaging technology, applied in the field of energy storage devices, can solve the problems of serious corrosion, no obvious effect of electrochemical corrosion, etc., and achieve the effect of good resistance to electrochemical corrosion and improvement of resistance to hydrofluoric acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

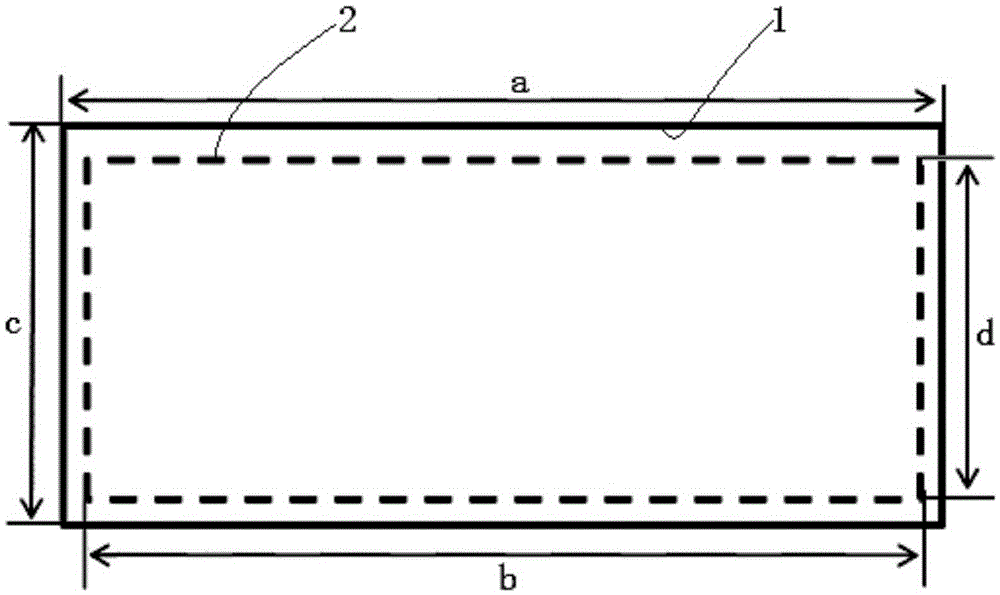

[0037] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. "Front", "back", "left", "right", "upper" and "lower" mentioned in the article refer to the lithium-ion battery flexible packaging material and the placement state of the lithium-ion battery using the material in the attached drawings .

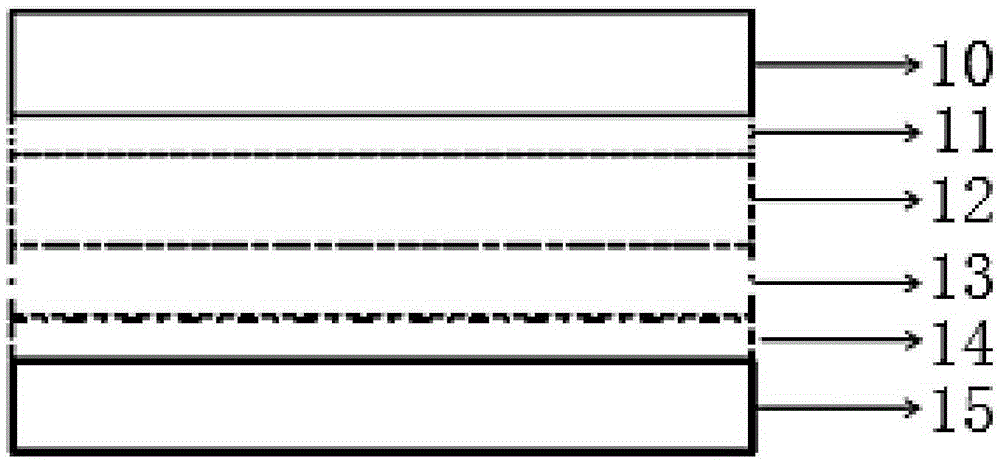

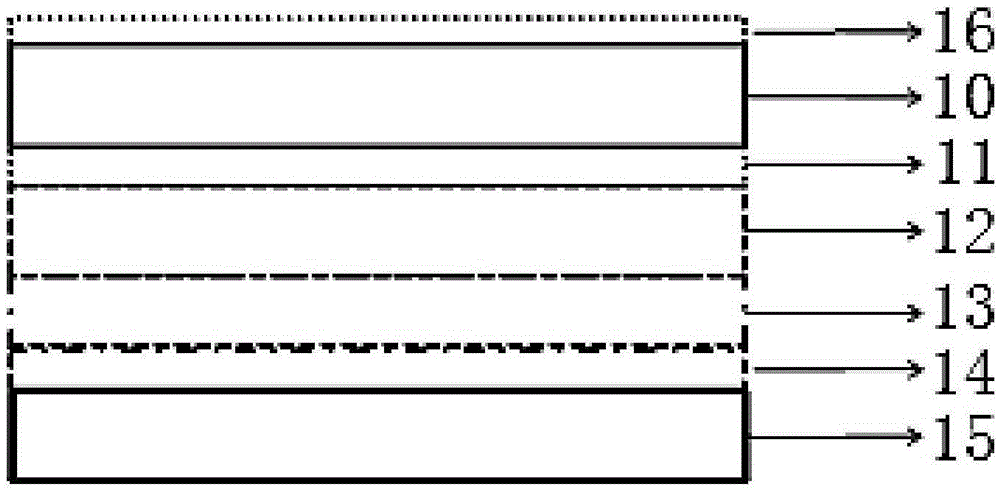

[0038] Such as figure 1 As shown, Embodiment 1 of the present application provides a flexible packaging material for lithium-ion batteries, the packaging material sequentially includes a substrate layer 10, a first adhesive layer 11, a metal foil layer 12, and an anti-corrosion treatment layer 13 from outside to inside. , the second adhesive layer 14 and the sealing layer 15 .

[0039] The base material layer 10 is located on the outside of the packaging material and plays the role of outer layer protection. It adopts a single-layer or multi-layer heat-resistant resin film. For the outer la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com