Super-capacitor energy storage type electric workover rig

A technology of electric workover rigs and supercapacitors, applied in electric vehicles, battery circuit devices, collectors, etc., can solve the problems of low work efficiency, low power, and low power of electric workover rigs, and achieve high operating efficiency and high performance Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

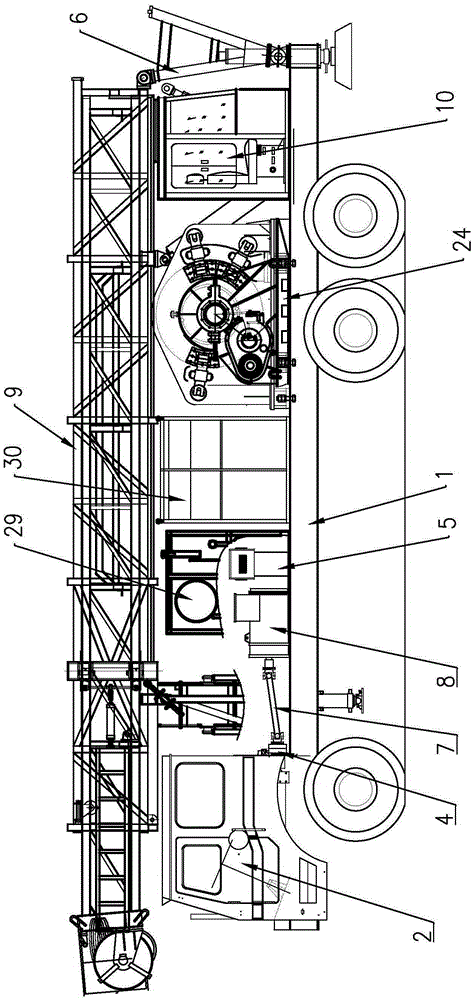

[0028] Such as figure 1 and figure 2 Shown, comprise the special automobile chassis 1 of workover rig, the front end of special automobile chassis 1 of workover rig is provided with driver's cab 2, the below of driver's cab 2 rear seats is provided with engine 3, is installed on the special automobile chassis 1 of workover rig Press 5, hydraulic station 29, electric control room 30, derrick 9 and workover operation room 10, the workover operation room 10 is located at the rear of the chassis 1 of the special vehicle for the workover rig, and the rear end of the derrick 9 is connected to the inverted triangle bracket 6 The top is hingedly connected, and the bottom end of the inverted triangular support 6 is installed on the tail of the special automobile chassis 1 of the workover rig;

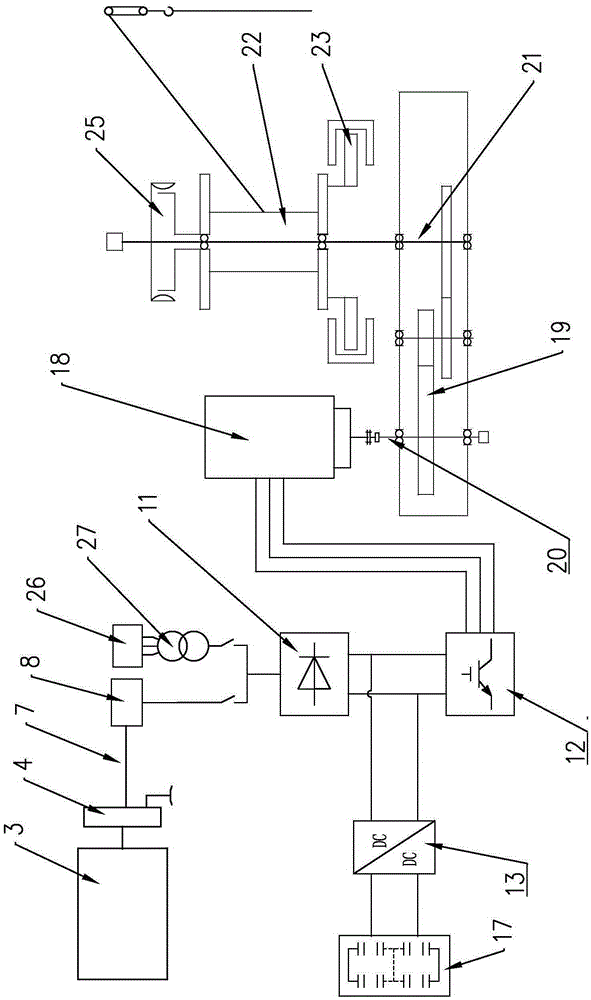

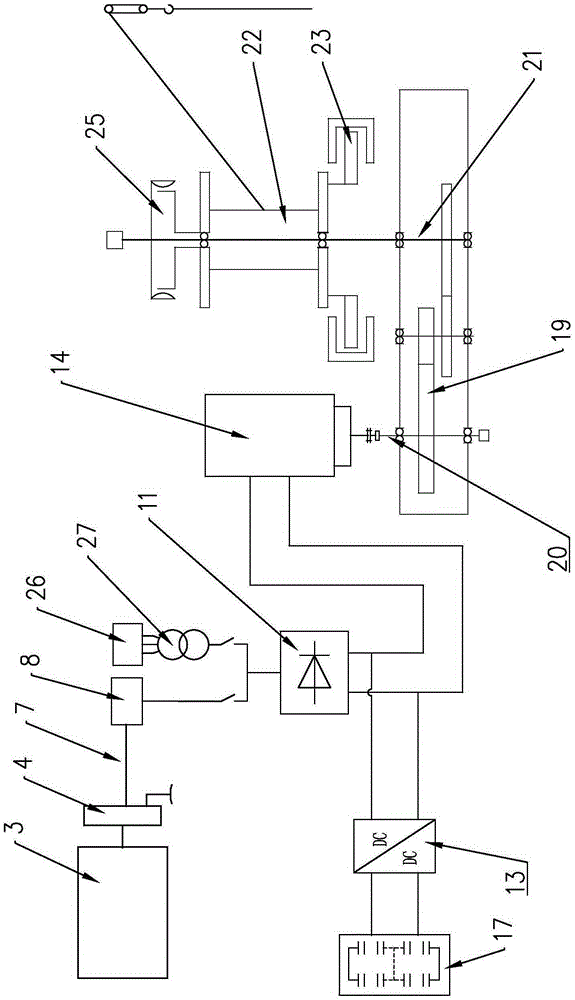

[0029] The automobile chassis 1 is provided with a supercapacitor power compensation device, and the supercapacitor power compensation device includes a rectifier circuit unit 11, the rectifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com