Riser for preparing chlorinated polyvinyl chloride through circulating fluidized bed

A technology of chlorinated polyvinyl chloride and circulating fluidized bed, which is applied in the field of riser to solve the problem of chlorination uniformity, improve safety and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

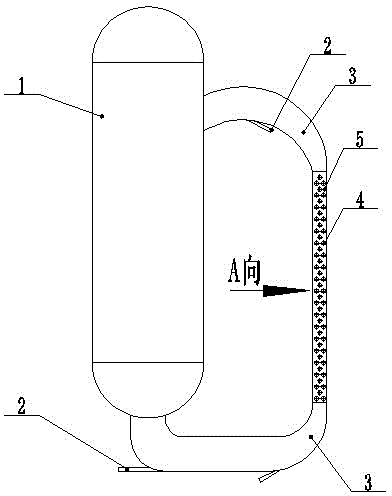

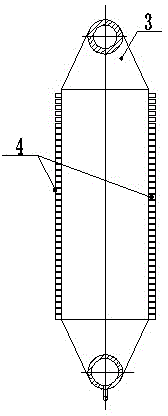

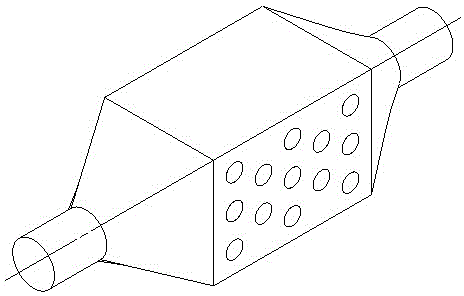

[0026] Embodiment 1, as specification attached Figure 1-5 , the riser device includes a connecting device 3, a rising pipe 4, a fixing device 5, and a purging device 2; Unicom; at least two corresponding fixing devices 5 are provided on any diagonal surface of the side wall of the riser 4; the fixing devices 5 are distributed in a dislocation array on the surface of the riser 4, and the center distance of the fixing devices 5 is an ultraviolet lamp 10 twice the diameter, the fixing device 5 includes a connecting pipe 6, a locking nut 7, a sealing ring 8, an outer pipe 9, and a fixed ring 11; the connecting pipe 6 is connected with the riser 4, and the outer pipe 9 is used The material is a silicon dioxide material, preferably quartz, which is horizontally inserted into the riser 4, and connected with the corresponding connecting pipe 6 on the diagonal surface, and its two ends are connected to the connecting pipe 6 through lock nuts 7 and sealing rings 8. Sealing, the ultrav...

Embodiment 2

[0029]Embodiment 2: with reference to attached Figure 1-5 , The difference between this embodiment and Embodiment 1 is that the distance between the centers of the fixing devices 5 is three times the diameter of the ultraviolet lamp 10 .

Embodiment 3

[0030] Embodiment 3: with reference to attached Figure 1-5 , The difference between this embodiment and Embodiments 1 and 2 is that the distance between the centers of the fixing devices 5 is 4 times the diameter of the ultraviolet lamp 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com