Detecting method for welding seam track of welding robot

A welding robot and trajectory technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor performance of welding robots, welding defects, low accuracy, etc., to facilitate measurement and analysis, and save detection. Cost, effect of accurate evaluation criteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

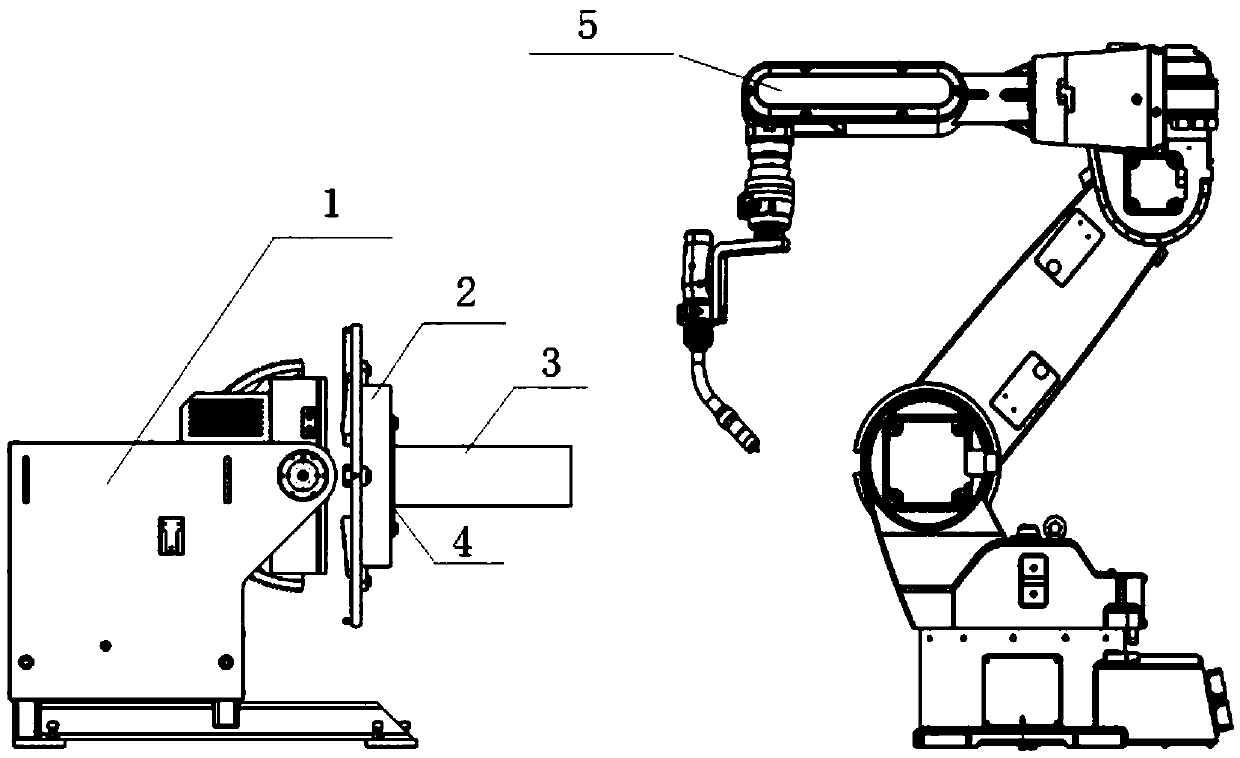

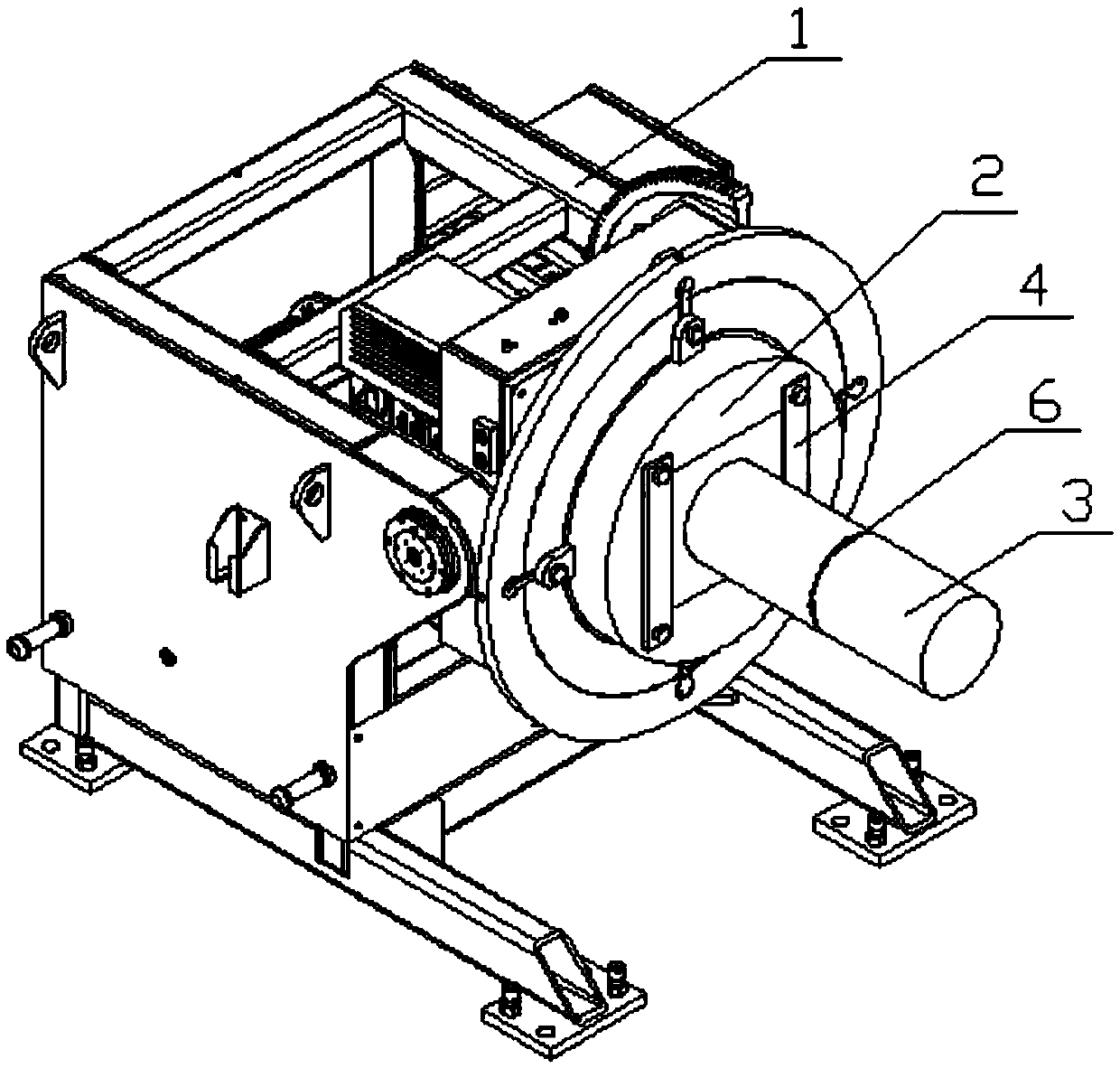

[0020] The present invention relates to a method for detecting a welding seam trajectory of a welding robot, comprising a welding robot 5, a tooling, a gypsum workpiece 3, a scratch steel needle, a positioner 1, a three-dimensional laser scanner, three-dimensional model software, three-dimensional modeling software and analysis software , the specific detection method is as follows:

[0021] a. Fix the gypsum workpiece 3 on the tooling;

[0022] b. Fix the tooling on the positioner 1, start the positioner 1, and the tooling moves with the disk of the positioner 1, thereby driving the gypsum workpiece 3 on the tooling to move;

[0023] c. Install the scratch steel needle on the welding torch head of the welding robot 5;

[0024] d. Adjust the distance between the welding robot 5 and the positioner 1 according to the welding requirements on site, start the welding robot 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com